If you’ve ever wondered if circular saw blades are hardened, you’re in the right place! In this article, we’ll dive into the fascinating world of saw blades and find out if they go through a hardening process. So, are you ready to uncover the truth about these essential tools?

When it comes to circular saw blades, hardness plays a crucial role in their performance. But what does it mean for a blade to be hardened? Well, it’s all about making the blade tougher and more durable. So, if you’re curious to know if saw blades undergo hardening, keep reading!

In this informative article, we’ll explore the ins and outs of circular saw blades and answer the burning question: are they hardened? So, let’s put on our safety goggles and embark on this exciting journey together!

Are Circular Saw Blades Hardened? A Closer Look at Blade Durability

If you’re an avid woodworker or construction enthusiast, you’ve likely come across circular saw blades in your projects. These blades are essential for making precise and efficient cuts through various materials, including wood, metal, and plastic. One question that often arises when choosing the right circular saw blade is whether or not they are hardened. In this article, we’ll dive into the topic of circular saw blade hardness, exploring what it means for a blade to be hardened and how it affects performance and durability.

Understanding Blade Hardness: The Basics

Before we delve into the specifics of circular saw blade hardness, let’s first understand what it means for a blade to be hardened. Blade hardness refers to the ability of a blade to resist wear and withstand the pressures and stresses encountered during cutting. Hardening a circular saw blade involves heat treating the steel blade to increase its hardness, thereby enhancing its performance and longevity.

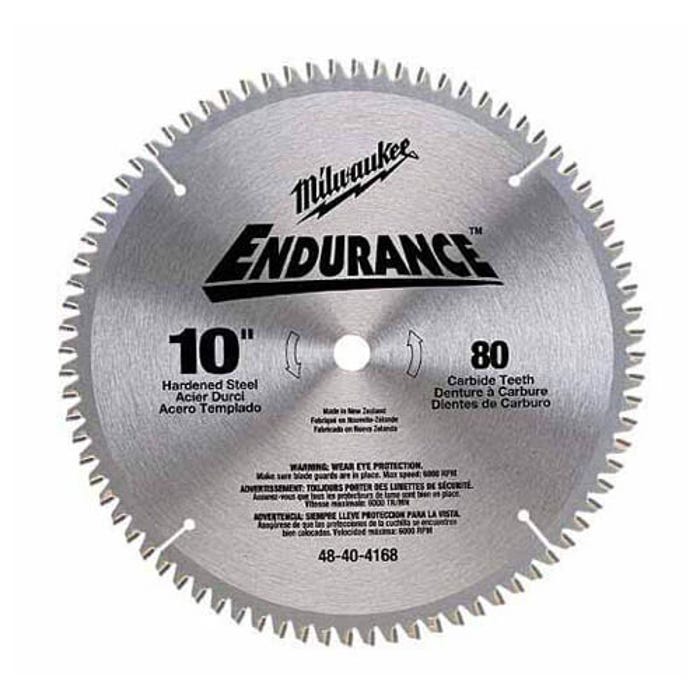

Most circular saw blades are made of high-speed steel (HSS) or carbide-tipped steel. HSS blades are known for their excellent cutting performance and ability to retain their sharpness for longer periods. On the other hand, carbide-tipped blades are renowned for their durability and long lifespan. Both types of blades can be hardened to different degrees, usually measured using the Rockwell C scale. A higher hardness rating indicates a more durable and wear-resistant blade.

The Benefits of Hardened Circular Saw Blades

Now that we understand what it means for a circular saw blade to be hardened let’s explore the benefits of using hardened blades for your cutting tasks.

1. Increased Cutting Performance: Hardened circular saw blades offer superior cutting performance compared to non-hardened blades. Their hardened edges retain their sharpness for longer, allowing for cleaner, more precise cuts and reduced effort during cutting.

2. Enhanced Durability: Hardened blades have a higher resistance to wear and can withstand the rigors of cutting through tough materials without dulling quickly. This means they have a longer lifespan and require less frequent replacement, saving you time and money in the long run.

3. Reduced Heat Build-up: The heat treatment process used to harden circular saw blades also helps in dissipating heat more efficiently. This reduces the risk of overheating during heavy cutting tasks, prolonging the blade’s life and maintaining its cutting performance.

Choosing the Right Hardened Circular Saw Blade

When it comes to choosing the right hardened circular saw blade for your needs, there are a few factors to consider:

- Material: Determine the type of material you’ll be cutting the most. Different blades are designed for specific materials, such as wood, metal, or plastic. Ensure the blade is hardened and optimized for the material you’ll be working with.

- Tooth Configuration: Consider the tooth configuration of the blade. Different tooth designs are suitable for different cutting applications, such as ripping or cross-cutting. Choose a blade with a tooth configuration that aligns with your specific cutting needs.

- Hardness Rating: Look for the hardness rating of the blade. The higher the rating, the more durable and wear-resistant the blade is likely to be.

- Manufacturer Reputation: Research and choose blades from reputable manufacturers known for their quality and durability.

Tips for Extending the Lifespan of Hardened Circular Saw Blades

To ensure the longevity of your hardened circular saw blades and maximize their performance, consider the following tips:

- Proper Cleaning: Regularly clean the blades to remove built-up debris and sawdust, which can affect cutting performance.

- Correct Storage: Store the blades in a dry, moisture-free environment to prevent rusting and corrosion.

- Proper Usage: Always use the appropriate blade for the specific material you’re cutting and avoid putting excessive pressure on the blade.

- Regular Inspections: Inspect the blades regularly for any signs of damage or wear, and replace them when necessary.

The Role of Blade Hardness in Performance and Longevity

Now that we’ve explored the concept of circular saw blade hardness and its benefits let’s dig deeper into the role it plays in the overall performance and longevity of the blades. Understanding this connection can help you make informed decisions when selecting the best circular saw blade for your cutting needs.

The Relationship Between Hardness and Cutting Speed

Blade hardness plays a crucial role in determining the cutting speed of a circular saw blade. Hardened blades have a higher resistance to wear, allowing them to maintain their sharpness for longer. This results in faster and more efficient cuts, as the blade can smoothly glide through the material without requiring excessive force or multiple passes. The increased cutting speed can significantly reduce the overall time spent on a project and increase productivity.

However, it’s important to strike the right balance between blade hardness and cutting speed. Blades that are too hard may become brittle and prone to chipping or cracking, especially when cutting through hard or dense materials. On the other hand, blades that are too soft may wear out quickly and lose their cutting efficiency, leading to poorer overall performance.

Durability and Blade Hardness

The hardness of a circular saw blade directly correlates with its durability and lifespan. Hardened blades are more resistant to wear and abrasion, allowing them to withstand the high pressures and stresses experienced during cutting. This increases their overall durability, making them ideal for heavy-duty cutting tasks and extended use.

Blades with lower hardness ratings may wear out more quickly, requiring frequent sharpening or replacement. This can be inconvenient and costly, especially for professional woodworkers or contractors who rely on their tools for daily use. Opting for hardened blades can help avoid these issues and provide a longer-lasting cutting solution.

Choosing the Right Hardness for Your Needs

It’s important to consider the specific requirements of your cutting tasks when choosing the hardness level of your circular saw blades. Different materials and cutting applications may necessitate different hardness ratings to achieve optimal results.

For example, if you primarily work with softwoods or non-abrasive materials, blades with a moderate hardness rating may be suitable. These blades offer a good balance between cutting speed and durability. On the other hand, if you frequently cut through hardwoods or abrasive materials, opting for blades with a higher hardness rating may be beneficial. These blades can withstand the higher levels of stress and offer longer cutting lifespans.

Final Thoughts

When it comes to circular saw blades, hardness plays a critical role in determining their performance and longevity. Hardened blades offer increased cutting performance, enhanced durability, and reduced heat build-up. By choosing the right hardness level for your specific cutting needs and following proper maintenance and usage practices, you can ensure that your circular saw blades provide optimal performance and last longer. Remember to carefully select blades from reputable manufacturers and consider factors such as material compatibility, tooth configuration, and hardness rating to make informed decisions.

Key Takeaways: Are Circular Saw Blades Hardened?

- Hardened circular saw blades are designed to be more durable and long-lasting.

- Hardening involves heating the blade and then rapidly cooling it to increase its hardness.

- Hardened blades can withstand the stress and friction during cutting tasks.

- Hardening also helps to prevent the blade from becoming dull quickly.

- It is important to check the specifications of a circular saw blade to know if it is hardened.

Frequently Asked Questions

In this section, we will answer some commonly asked questions about circular saw blades and whether they are hardened.

What does it mean for a circular saw blade to be hardened?

When a circular saw blade is hardened, it means that the blade undergoes a special heat treatment process to increase its hardness and durability. This process involves heating the blade to a high temperature and then rapidly cooling it. This hardening process helps the blade withstand the cutting forces and abrasion that it experiences during use.

Hardened circular saw blades are able to cut through materials such as wood, metal, or plastic more effectively and with less wear. They are less likely to become dull quickly, which can save time and money in the long run.

Do all circular saw blades come already hardened?

No, not all circular saw blades come hardened. Some blades are manufactured from materials that are naturally hard and do not require additional heat treatment. These blades are often made from high-quality steel or carbide, which provide excellent strength and durability without the need for hardening.

On the other hand, there are blades that are not hardened during the manufacturing process. These blades are typically made from softer materials and may require hardening to improve their cutting performance and longevity. It is important to check the manufacturer’s specifications or product information to determine if a particular circular saw blade is hardened or not.

Are hardened circular saw blades better than non-hardened ones?

While hardened circular saw blades offer greater durability and cutting performance, that doesn’t necessarily mean they are always better than non-hardened blades. The choice between the two depends on the specific cutting application and the materials being cut.

For cutting harder materials like metal or dense hardwoods, hardened blades are generally recommended due to their ability to withstand the high cutting forces and maintain sharpness. However, for softer materials like plywood or plastics, non-hardened blades may offer sufficient cutting performance at a lower cost.

How can I tell if a circular saw blade is hardened?

Identifying whether a circular saw blade is hardened or not can sometimes be challenging. The best way to determine the hardness of a blade is to consult the manufacturer’s specifications or product information. This should indicate whether the blade has undergone a hardening process or if it is made from naturally hard materials like carbide or high-quality steel.

Additionally, hardened circular saw blades often have a distinctive color or coating. They may be treated with a black oxide or a titanium-nitride coating, which improves their resistance to corrosion and wear. These coatings can serve as visual cues to indicate the presence of hardening.

Can I sharpen a hardened circular saw blade?

Sharpening a hardened circular saw blade can be more challenging compared to sharpening non-hardened blades. However, it is still possible to sharpen a hardened blade with the right tools and techniques. It is recommended to seek professional sharpening services or consult the manufacturer for guidance on sharpening hardened blades.

If you attempt to sharpen a hardened blade yourself, be sure to use a diamond file or a specialized sharpening tool designed for hardened blades. Take caution and follow the proper sharpening procedure to avoid damaging the blade or compromising its hardening.

Can You Harden a Saw Blade?

Summary

Circular saw blades are hardened to make them stronger and more durable. Hardening involves heating the blade to a high temperature and then rapidly cooling it. This process creates a hard outer layer that can withstand the pressure and friction of cutting through materials. However, the inner core of the blade remains softer to provide flexibility.

It is important to note that not all circular saw blades are hardened. Some cheaper blades are not hardened and may wear down more quickly. Hardening also affects the type of material that the blade can cut. Blades made for cutting metal, for example, are typically harder than blades for cutting wood. So if you’re using a circular saw blade, it’s a good idea to check if it is hardened and suitable for the material you are cutting.