If you’ve ever wondered, “Are circular saw blades universal?” then you’ve come to the right place. Well, let me tell you, my curious friend, the answer isn’t as simple as a yes or no. You see, when it comes to circular saw blades, there are a few factors that determine their compatibility. Let’s dive in and explore this captivating topic!

So, here’s the deal: circular saw blades come in different sizes, types, and designs. They’re like puzzle pieces that need to fit perfectly into the saw’s arbor. And that’s where the magic happens! You need to make sure the blade you choose matches your saw’s specifications, like its diameter and arbor size. It’s like finding the perfect pair of shoes that fit just right!

But don’t fret, my young apprentice of the woodworking realm! While circular saw blades may not be universally interchangeable, fear not, for there are many standard sizes available in the market. So, once you know your saw’s blade requirements, you’ll have plenty of options to choose from—a world of possibilities for all your cutting adventures!

So, dear reader, remember this: the compatibility of circular saw blades depends on various factors, including the size and design of the blade, as well as the specifications of your trusty saw. Now that we’ve laid the groundwork, let’s explore further and uncover the secrets of circular saw blades together! Buckle up, my friend, because we’re about to embark on an exciting journey into the world of circular saws!

Are Circular Saw Blades Universal?

In the world of woodworking and construction, circular saws are indispensable tools for cutting various materials with precision. One common question that arises is whether circular saw blades are universal. Can any blade fit any circular saw? In this article, we will explore the compatibility of circular saw blades and shed light on the factors to consider when choosing the right blade for your saw.

Factors to Consider When Choosing Circular Saw Blades

When it comes to circular saw blades, compatibility is not as straightforward as one might think. There are several factors to consider when selecting the right blade for your saw. Let’s take a closer look at these factors:

1. Blade Diameter

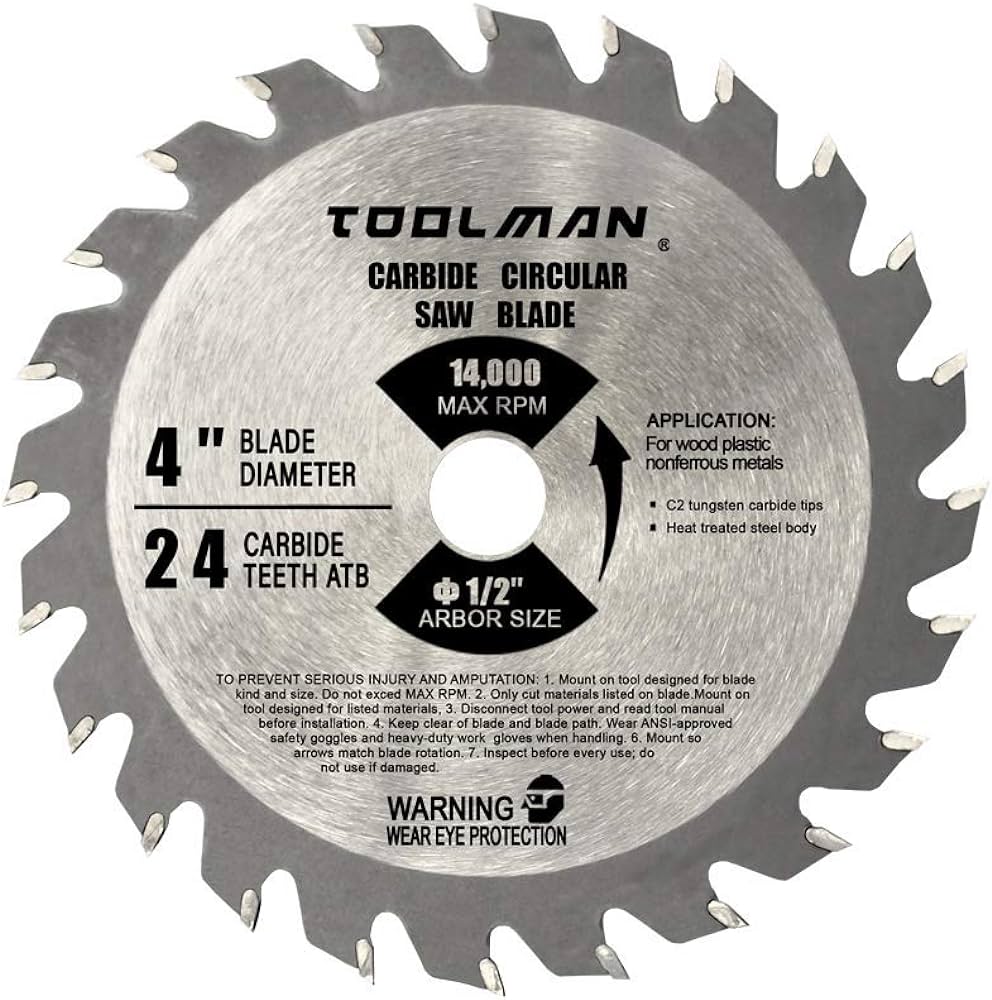

The diameter of a circular saw blade refers to the size of the blade itself. Most circular saws have a recommended blade diameter range, and it is crucial to choose a blade that falls within this range. Using a blade with a diameter outside the recommended range can result in poor performance, inaccurate cuts, and even damage to the saw.

It is important to note that different sizes of circular saws have different blade diameters. For example, a standard 7.25-inch circular saw requires a blade with a 7.25-inch diameter. Therefore, it is essential to check the specifications of your circular saw and choose a blade that matches its recommended diameter range.

Beyond the diameter, the thickness of the blade should also be taken into consideration. Blades that are too thick may not fit in the saw, while blades that are too thin may cause vibration and lead to imprecise cuts.

2. Arbor Size

The arbor size of a circular saw blade refers to the diameter of the hole at the center of the blade where it attaches to the saw’s arbor. It is crucial to choose a blade with a compatible arbor size to ensure a secure and tight fit. Most circular saws have a standard arbor size, commonly 5/8-inch or 1-inch, but there are variations, so it is important to check the specifications of your saw.

Using a blade with the wrong arbor size can lead to dangerous situations as the blade may not be securely fastened to the saw. It can cause excessive vibration, increased risk of kickback, and compromised cutting performance. Therefore, always ensure that the arbor size of the blade matches the arbor size of your circular saw.

3. Blade Type and Material

Circular saw blades come in various types and materials, each designed for specific cutting applications. Understanding the different blade types and materials is crucial in selecting the right blade for your specific needs.

Some common blade types include rip-cut blades, crosscut blades, and combination blades. Rip-cut blades have fewer teeth and are ideal for cutting along the wood grain, while crosscut blades have more teeth and are suitable for cutting across the grain. Combination blades, as the name suggests, are versatile and can handle both rip-cutting and crosscutting tasks.

The material of the blade also plays a significant role in its performance. Blades with carbide-tipped teeth offer excellent durability and can withstand the rigors of cutting through various materials, including wood, metal, and plastic. High-speed steel blades, on the other hand, are more affordable but tend to wear down faster.

4. Cutting Depth and Bevel Capacity

In addition to the blade’s diameter and arbor size, it is crucial to consider the cutting depth and bevel capacity of the blade. The cutting depth refers to how deep the blade can cut into the material, while the bevel capacity refers to the blade’s ability to make angled cuts.

It is essential to choose a blade that matches the cutting depth and bevel capacity requirements of your specific cutting tasks. Using a blade with insufficient cutting depth can result in incomplete cuts, while using a blade with limited bevel capacity can hinder your ability to make angled cuts effectively.

5. Safety Considerations

When selecting a circular saw blade, it is vital to prioritize safety. Always choose blades with proper safety features, such as anti-kickback design and laser-cut expansion slots. Additionally, ensure that the blade is appropriate for the material you are cutting and follows all safety guidelines provided by the saw manufacturer.

Remember, the right blade not only enhances cutting performance but also minimizes the risk of accidents and injuries. Prioritize safety above all else when choosing a circular saw blade.

6. Specialty Blades

In addition to standard circular saw blades, there are also specialty blades available for specific cutting tasks. These include blades for cutting metal, concrete, ceramic tiles, and other specialized materials. If you frequently work with these materials, investing in specialty blades can significantly improve your cutting efficiency and the quality of your results.

It is important to note that specialty blades may have different compatibility requirements or may only be suitable for specific saw models. Always check the specifications and recommendations provided by the blade manufacturer to ensure compatibility and optimal performance.

7. Blade Maintenance and Lifespan

Proper blade maintenance is essential for ensuring longevity and optimal cutting performance. Regularly cleaning and sharpening the blade can significantly extend its lifespan and prevent issues such as dullness and overheating. Additionally, properly storing the blade and protecting it from moisture and rust will also contribute to its longevity.

When a blade becomes too dull or damaged beyond repair, it is important to replace it promptly. Continuing to use a worn-out blade not only compromises the quality of your cuts but also poses safety risks. Regularly inspect your blades for signs of wear and tear and replace them as needed to maintain optimal cutting performance.

Choosing the Right Circular Saw Blade

Now that we have explored the various factors to consider when choosing a circular saw blade, let’s summarize the key points:

- Consider the blade diameter and ensure it falls within the recommended range for your saw.

- Check the arbor size and choose a blade that matches the arbor size of your circular saw.

- Understand the different blade types and materials and select the appropriate one for your cutting tasks.

- Consider the cutting depth and bevel capacity requirements of your specific projects.

- Prioritize safety by choosing blades with proper safety features and following all manufacturer guidelines.

- Consider specialty blades for specific cutting tasks or materials.

- Maintain and replace blades regularly to ensure optimal performance and safety.

By taking these factors into account and making an informed decision, you can confidently choose the right circular saw blade for your needs. Remember, the blade is a crucial component of your saw, and selecting the right one will greatly impact your cutting performance and overall woodworking experience.

Key Takeaways: Are Circular Saw Blades Universal?

- Not all circular saw blades are universal, as they come in various sizes and types.

- It is important to match the blade size and type with the specific saw you have.

- There are different blades for cutting wood, metal, and other materials.

- Some saws may require specific blade attachments or adapters to use a different blade.

- Always refer to the manufacturer’s instructions and recommendations for the correct blade.

Frequently Asked Questions

In the world of circular saw blades, there can be confusion about their universality. Here are some common questions and answers to help clear things up.

1. Can any circular saw blade fit on any circular saw?

The short answer is no. While there are similarities between circular saw blades, they are not always universal. Circular saw blades come in different sizes, with variations in diameter, arbor size, and blade type. It’s crucial to choose a blade that matches your specific circular saw model to ensure compatibility and optimal performance.

Before purchasing a new circular saw blade, consult your saw’s user manual or manufacturer’s website to determine the blade specifications that are compatible. This way, you can ensure a proper fit and achieve the best results when cutting.

2. Are circular saw blades interchangeable between brands?

Interchanging circular saw blades between different brands can be risky. Although there are standards for blade sizes and arbor hole dimensions, there may still be variations between brands. It is recommended to use blades specifically designed for your circular saw’s brand to ensure compatibility, safety, and performance.

Blades from the same brand are more likely to have a perfect fit and alignment with the saw, optimizing cutting precision and reducing the risk of accidents. Following the manufacturer’s recommendations for blade selection will help maintain the warranty coverage and keep you safe while operating the saw.

3. Can a larger diameter blade be used on a smaller circular saw?

No, it is not recommended to use a larger diameter blade on a smaller circular saw. Each circular saw has a maximum blade diameter it can accommodate, and going beyond that limit can cause severe safety hazards and damage to both the blade and the saw.

A larger blade may protrude from the saw’s guard or housing, increasing the risk of kickback, binding, or the blade contacting the work surface inappropriately. Always follow the manufacturer’s guidelines and use the correct blade size recommended for your specific circular saw.

4. Do all circular saw blades have the same tooth count and shape?

Circular saw blades come with different tooth counts and shapes, designed for specific cutting applications. It’s essential to select the appropriate blade for the task at hand to achieve desired results.

The tooth count on a circular saw blade determines the cutting speed and the finish quality. Blades with fewer teeth perform faster but may leave a rougher finish, while blades with more teeth produce smoother cuts but can slow down the cutting process. Similarly, different blade shapes, such as rip blades or crosscut blades, are optimized for specific cutting needs.

5. Can I use the same circular saw blade for different materials?

While some circular saw blades can handle multiple materials, it is generally recommended to use blades specifically designed for the material you are cutting. Blades designed for wood may not be suitable for cutting metal or masonry, and vice versa.

Using the right blade for the material not only ensures clean and precise cuts but also prolongs the life of the blade. Material-specific blades have features and coatings that enhance their performance and durability when cutting through specific materials.

Summary

Circular saw blades are not universal and come in different sizes and types to fit specific needs. It is important to choose the right blade for the material you are cutting, such as wood or metal. Using the wrong blade can result in poor performance and even damage to the saw or material.

Additionally, circular saw blades have different arbor sizes, which is the hole in the center where they attach to the saw. It is crucial to match the blade’s arbor size to the saw’s arbor size for a proper fit. Always refer to the manufacturer’s instructions and consult a professional if you are unsure about which blade to use.

In conclusion, understanding that circular saw blades are not universal and selecting the right blade for the job is essential for safety and optimal performance.