If you’re someone who enjoys learning about machinery or has an interest in woodworking, you might have come across a lathe machine. But have you ever wondered, “Are lathe machines dangerous?” Well, in this article, we’re going to explore this question and shed some light on the potential hazards associated with these powerful tools. So, let’s dive in and find out if working with a lathe machine requires extra caution.

When it comes to using any type of machinery, safety should always be a top priority. Now, you might be wondering, “Why should I be concerned about lathe machine safety?” Well, lathe machines can pose certain risks if not handled correctly. In the next few paragraphs, we’ll discuss some of the potential dangers and how to stay safe while operating a lathe machine.

But don’t worry, we’re not here to scare you away from exploring the world of lathe machines. Instead, our goal is to equip you with knowledge and guidelines on how to use these machines safely. So, let’s get started and learn how to enjoy the thrill of working with a lathe machine while minimizing the risks involved.

Lathe machines can be dangerous if not used properly. Understanding and adhering to safety guidelines is crucial in minimizing the risk of accidents. Always wear appropriate safety gear, such as goggles and gloves, when operating a lathe machine. Keep long hair and loose clothing secured and away from moving parts. Ensure the machine is properly maintained and that all safety features are functional. Understanding the machine’s operations and practicing proper techniques will help prevent accidents and maintain a safe working environment.

Are Lathe Machines Dangerous? The Essential Guide to Safety and Best Practices

Lathe machines are powerful tools used in a variety of industries for shaping and cutting materials. While lathe machines are incredibly useful, they can also pose safety risks if not used properly. In this guide, we will explore the potential dangers of lathe machines and provide you with essential safety tips to ensure your well-being while operating these machines. Whether you are a beginner or an experienced operator, this guide will equip you with the knowledge and precautions necessary to work safely with lathe machines.

The Importance of Worksite Safety

Your safety should be the top priority when working with any machinery, and lathe machines are no exception. It is crucial to understand the potential risks associated with lathe machines and take the necessary precautions to mitigate them. By following proper safety practices, you can prevent accidents, injuries, and even fatalities. Let’s dive into the key safety aspects of working with lathe machines.

Proper Safety Gear

When operating a lathe machine, it is essential to wear the appropriate safety gear to protect yourself from potential hazards. This includes safety glasses or goggles to shield your eyes from flying debris or particles. Ear protection, such as earmuffs or earplugs, is crucial to prevent hearing damage caused by the machine’s noise. Additionally, wearing protective gloves and clothing can minimize the risk of injury from sharp tools or rotating parts.

It is also important to ensure that the work area has proper lighting to enhance visibility and reduce the chances of accidents. Adequate ventilation is necessary to prevent the buildup of fumes, dust, or other harmful particles. By wearing the right safety gear and maintaining a safe working environment, you can significantly reduce the risk of accidents while operating a lathe machine.

Machine Maintenance and Inspection

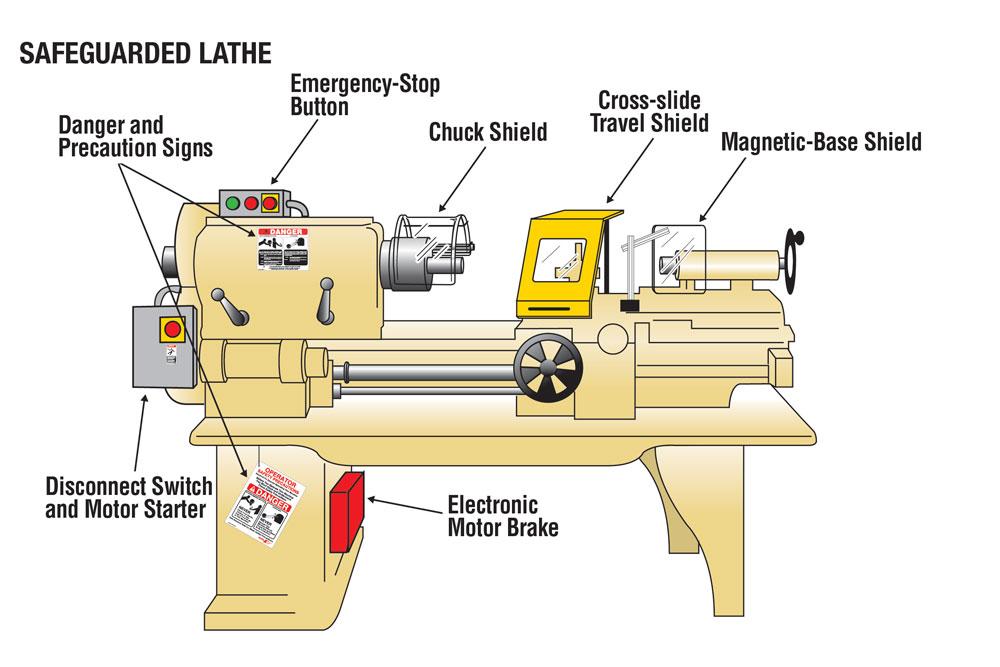

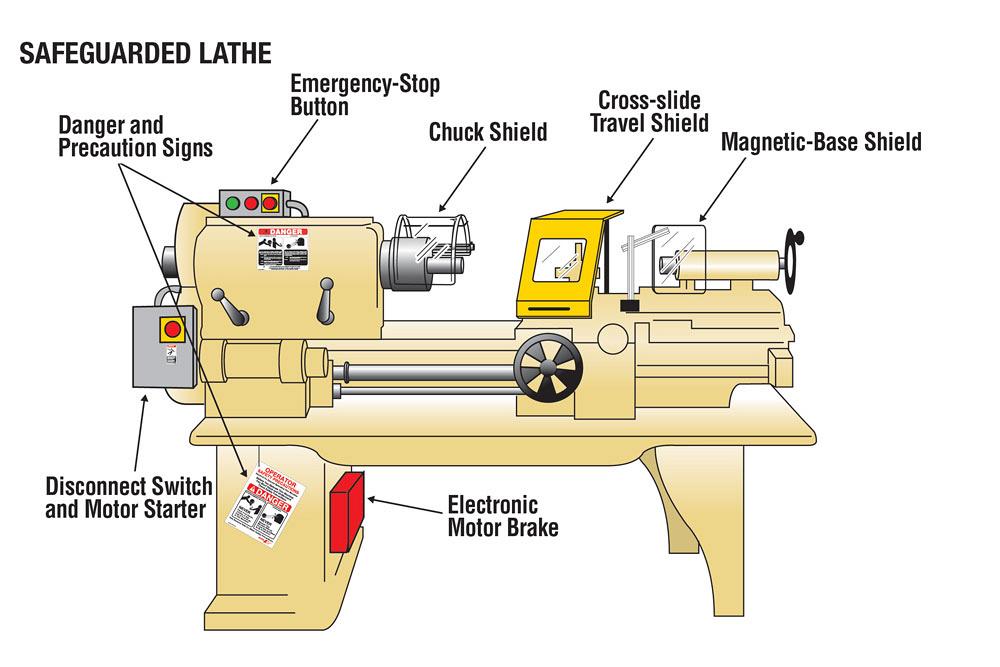

Regular maintenance and inspections are vital for ensuring the safe and efficient operation of a lathe machine. Before using the machine, thoroughly inspect it for any signs of damage or wear. Check for loose or missing parts, damaged cables or belts, and any other potential issues. If any problems are detected, do not attempt to use the machine until the necessary repairs are made.

Regular lubrication of moving parts is crucial to reduce friction and prevent overheating. Refer to the machine’s manual for specific lubrication requirements and adhere to the recommended schedule. Additionally, ensure that the lathe machine is properly grounded to prevent electrical shocks or other electrical hazards. Regular maintenance and inspections will help identify and address any potential safety risks before they escalate into more significant issues.

Safe Operating Procedures

Following safe operating procedures is paramount to minimize the risk of accidents while using a lathe machine. Familiarize yourself with the specific machine’s operating manual and instructions provided by the manufacturer. This will ensure that you understand all the safety features, controls, and procedures for safe operation.

Always double-check the workpiece and tool alignment before starting the machine. Ensure that the tools are properly secured and the workpiece is adequately supported. Do not overload the machine or attempt to force the cutting tools beyond their capacity. Keep your hands and loose clothing away from the moving parts and rotating chucks. Avoid reaching into the machine while it is in operation and use appropriate tools or accessories for adjustments or repairs.

Finally, never leave the lathe machine unattended while it is running. If you need to step away, turn off the machine and wait for it to come to a complete stop before leaving the workstation. By adhering to safe operating procedures, you can significantly reduce the risk of accidents or injuries associated with lathe machines.

Employee Training and Supervision

Providing thorough training and supervision to employees who operate lathe machines is of utmost importance. Employers should conduct comprehensive training programs that cover the safe operation, maintenance, and emergency procedures associated with lathe machines. It is crucial to ensure that operators are well-informed about the potential risks and are equipped with the necessary skills to work safely.

Furthermore, supervisors should regularly monitor and assess employees’ adherence to safety protocols. They should be readily available to address any concerns, provide guidance, and oversee the safe operation of the machines. By investing in employee training and maintaining adequate supervision, companies can create a safer work environment and minimize the likelihood of accidents.

Choosing the Right Lathe Machine for the Job

When it comes to purchasing or using a lathe machine, selecting the right one for the job is crucial for both efficiency and safety. Here are some key factors to consider when choosing a lathe machine:

Type of Lathe Machine

There are various types of lathe machines available, each designed for specific purposes. Determine the type that best suits your needs, whether it’s a bench lathe, engine lathe, or CNC lathe. Consider factors such as the size of the workpiece, complexity of the task, and desired accuracy.

Machine Size and Power

The size and power of the lathe machine should align with the scale of your projects. A larger machine may be necessary if you frequently work on larger workpieces, while a smaller machine can be more suitable for small-scale projects.

Features and Accessories

Consider the additional features and accessories offered by different lathe machines. These can include digital readouts, automatic tool changers, or coolant systems. Assess whether these features are necessary for your work requirements.

Manufacturer Reputation and Support

Research the reputation and after-sales support of the manufacturer before making a purchase. Opt for renowned brands with a track record of producing reliable and high-quality machines. This ensures that you will receive proper technical support and assistance if any issues arise.

Conclusion

Lathe machines are powerful tools with the potential for both productivity and danger. However, by prioritizing safety, following proper procedures, and investing in the right equipment, you can mitigate the risks and create a safe work environment. Remember to follow all safety guidelines, wear the necessary protective gear, and maintain the machine regularly. By doing so, you can enjoy the benefits of working with a lathe machine while ensuring your well-being.

Key Takeaways – Are Lathe Machines Dangerous?

1. Lathe machines can be dangerous if not used properly.

2. Operating a lathe machine requires proper training and safety precautions.

3. Wearing protective clothing and safety equipment is important when using a lathe machine.

4. Keep hands and loose clothing away from rotating parts of the machine.

5. Regular maintenance and inspections are necessary to ensure safe operation of lathe machines.

Frequently Asked Questions

When it comes to working with lathe machines, safety is of utmost importance. Here are some commonly asked questions about the potential dangers of lathe machines, along with their answers:

1. How can lathe machines be dangerous?

Lathe machines can be dangerous due to the fast-moving spinning motion of the workpiece and the sharp cutting tools involved. If not properly operated or with inadequate safety precautions, there is a risk of accidents such as entanglement, flying debris, and contact with the rotating parts. These hazards can lead to serious injuries.

It is crucial to follow proper procedures, wear appropriate personal protective equipment, and receive proper training before operating lathe machines to minimize the associated risks.

2. What safety measures should I take when working with lathe machines?

When using a lathe machine, it is important to adhere to several safety measures. First and foremost, always wear suitable protective equipment, including safety glasses, gloves, and a face shield. Securely fasten the workpiece, ensuring it is properly supported and balanced to avoid excessive vibrations. Keep your hands away from rotating parts, and use a tool rest to maintain a safe distance from the cutting tools.

Additionally, familiarize yourself with emergency stop procedures and keep the work area clean and free from obstructions. Regularly inspect and maintain the machine to ensure it is in good working condition. By following these safety measures, you can minimize the risks associated with operating lathe machines.

3. Can lathe machines cause hand injuries?

Yes, lathe machines can cause hand injuries if not used with caution. The rotating parts of the lathe machine can catch loose clothing, long hair, or jewelry, which can result in severe entanglement or finger injuries. It is essential to avoid wearing loose-fitting clothing, tie back long hair, and remove any jewelry before operating the machine.

Properly securing the workpiece and using appropriate tools, such as chucks and handles, can also ensure a firm grip and minimize the risk of hand injuries. Remember to always remain focused and attentive while operating the lathe machine to prevent any accidents.

4. Are there any electrical hazards associated with lathe machines?

Yes, electrical hazards can be associated with lathe machines. These hazards arise from improper grounding, damaged electrical cords, or faulty electrical components. To reduce the risk of electrical accidents, ensure that the machine is properly grounded and regularly inspect the electrical system for any signs of damage or wear.

It is also important to keep the work area dry and avoid exposing electrical parts to moisture. If you notice any electrical issues, such as flickering lights or sparking, immediately disconnect the machine and have it inspected by a qualified professional to prevent any potential electrical hazards.

5. What precautions should be taken to prevent flying debris?

Flying debris is a potential hazard when using lathe machines. To prevent the risk of injury from flying debris, always wear safety goggles or a face shield to protect your eyes and face. Make sure the lathe machine is equipped with appropriate guarding to contain the debris.

In addition, use the appropriate cutting tools for the specific type of material you are working with. This reduces the likelihood of excessive vibrations or tool breakage, which can lead to flying debris. Regularly inspect the cutting tools for signs of wear or damage, and replace them as needed. Taking these precautions will go a long way in ensuring your safety when operating lathe machines.

Lathe incident

Summary: Are Lathe Machines Dangerous?

Lathe machines can be dangerous if not used with caution and proper safety measures in place. They have rotating parts that can cause severe injuries if not handled correctly.

Safety precautions such as wearing protective gear, keeping a safe distance from rotating parts, and using tools properly are crucial to prevent accidents. It’s important to receive proper training and guidance before operating a lathe machine to ensure safety.

Although lathe machines can be dangerous, with the right precautions and knowledge, they can be used safely and effectively for various tasks. Always prioritize safety and follow guidelines to minimize the risk of accidents and injuries.