Are you curious about power tools and whether or not they are insulated? Well, you’ve come to the right place! In this article, we’ll explore the world of power tools and dive into the topic of insulation. So, let’s get started and find out if power tools are insulated!

When it comes to power tools, safety is always a top concern. You want to make sure that you’re using tools that are not only efficient but also safe to operate. That’s where insulation comes into play. Insulation in power tools helps protect the user from electrical shocks and prevents accidents. But the question remains, are power tools really insulated?

Whether you’re a budding DIY enthusiast or just curious about the inner workings of power tools, understanding insulation is key. Join us as we navigate through the world of power tools and reveal the truth about their insulation. So, let’s get right into it and discover if power tools are indeed insulated!

Are Power Tools Insulated? Unraveling the Mystery

Welcome to our comprehensive guide on power tool insulation. If you’re a DIY enthusiast or a professional tradesperson, you’ve likely wondered about the safety measures in place to prevent electric shock while using power tools. In this article, we’ll delve deep into the world of power tool insulation, exploring how it works, its importance, and the different types of insulation available. So, let’s get started and shed some light on this intriguing topic.

Understanding Power Tool Insulation: What Is It?

Power tool insulation is a protective measure that prevents electric shock to users. It’s a crucial safety feature incorporated into the design and construction of power tools. Insulation acts as a barrier between the electrical components of the tool and the user, minimizing the risk of accidental electric shock.

The insulation material used in power tools is typically specialized rubber or plastic, carefully chosen for its ability to withstand high voltage and heat. This insulation encompasses various parts of the power tool, including the handle, housing, and other potential contact areas. By isolating the live parts of the tool, insulation shields users from direct exposure to electricity, providing a safer working environment.

It’s important to note that insulation doesn’t eliminate the need for proper electrical safety practices such as using grounded power outlets, wearing appropriate personal protective equipment (PPE), and following manufacturer guidelines. Rather, insulation acts as an additional layer of protection, greatly reducing the risk of electric shock.

The Importance of Power Tool Insulation: Safety First

In the realm of power tools, safety should always be the top priority. Power tool insulation plays a vital role in ensuring user safety by significantly reducing the risk of electrical accidents. Here are some key reasons why power tool insulation is of utmost importance:

- Prevents Electric Shock: The primary function of power tool insulation is to safeguard users from electric shock. A well-insulated tool minimizes the chance of coming into direct contact with live electrical components, protecting users from potentially fatal or harmful shocks.

- Enhances User Confidence: Insulated power tools instill confidence in users, allowing them to focus on the task at hand rather than worrying about electrical safety. With the knowledge that their power tool has been designed with adequate insulation, users can work with peace of mind.

- Complies with Safety Standards: Power tool insulation is a requirement set by safety standards organizations to ensure the design and manufacture of safe tools. Adhering to these standards guarantees that power tools meet the necessary safety regulations.

Types of Power Tool Insulation: Exploring the Options

Power tool insulation comes in various forms, each offering its own set of benefits. Let’s take a closer look at the different types of insulation you’ll find in power tools:

1. Double Insulation:

Double insulation, also known as “Class II insulation” or “double insulated class,” is a popular choice among power tool manufacturers. This type of insulation relies on a combination of insulation materials and design features to provide an extra layer of protection. Double insulation is often recognizable by a distinct symbol – a square within a square. Tools with double insulation eliminate the need for a ground connection, making them safer to use in environments where grounding may be a challenge.

2. Grounding:

While not a form of insulation itself, grounding is an essential element of electrical safety in power tools. Some tools feature grounding as an additional safety measure, ensuring any electrical faults are directed away from the user. Grounding involves connecting one or more conductive components of the tool to an external grounding conductor, typically through a grounding plug or wire.

3. Insulated Handles:

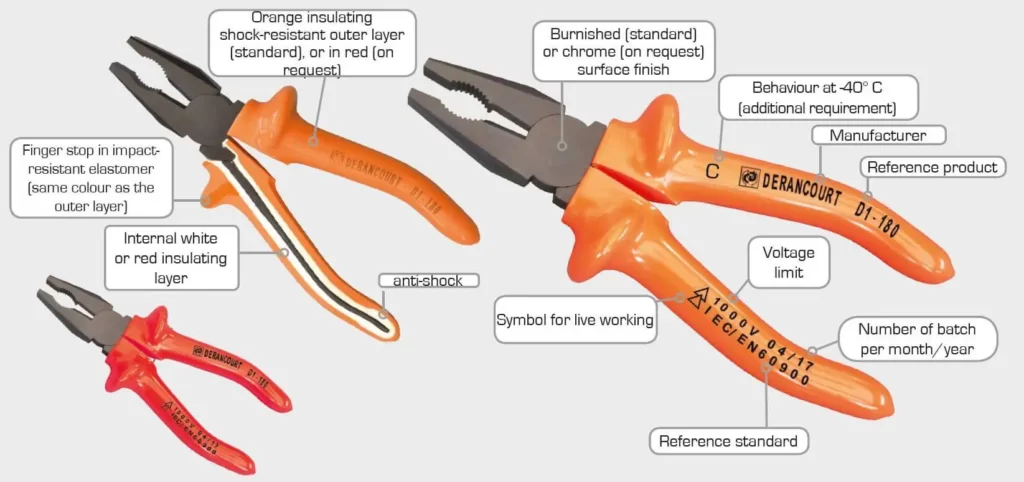

Many power tools incorporate insulated handles as a means of protecting users from potential electrical hazards. Insulated handles are made from specialized materials that have excellent electrical insulation properties. By isolating the handle from the tool’s internal electrical components, these handles greatly reduce the risk of electric shock during use.

4. Insulated Housing and Casing:

Insulation is not limited to just handles; power tools often feature insulated housing and casing as well. The housing and casing materials contribute to the overall safety and insulation of the tool, providing an extra layer of protection. These insulated components ensure that even accidental contact with live parts of the tool won’t result in an electric shock.

5. Impact-Resistant Insulation:

Power tools designed for rugged use, such as construction tools, may utilize impact-resistant insulation. This type of insulation is durable and can withstand the rough handling and accidental drops that often occur in demanding work environments. Impact-resistant insulation provides an added layer of protection against damage that could compromise the tool’s insulation capabilities.

Power tool insulation is a critical safety feature that should not be overlooked. Understanding the various types of insulation available allows users to make informed decisions when selecting power tools for their specific needs. By choosing tools with the appropriate insulation, users can ensure they have an added layer of protection against electrical hazards.

Power Tool Insulation Maintenance: Keeping Yourself Safe

Now that we’ve explored the ins and outs of power tool insulation, it’s important to consider the maintenance and care required to keep yourself safe. Adhering to proper maintenance practices ensures that your power tools remain well-insulated and in optimal working condition. Here are a few tips to help you with power tool insulation maintenance:

Regular Cleaning and Inspection

To maintain the integrity of your power tool’s insulation, it’s essential to keep it clean and inspect it regularly. Dust, dirt, and debris can accumulate over time and compromise the insulation properties. Clean your power tools using manufacturer-recommended methods and inspect them for any signs of damage, wear, or loose connections. Replace any damaged parts or components promptly.

Store Power Tools Properly

Proper storage of power tools is another crucial aspect of insulation maintenance. Make sure to store your tools in a clean, dry area away from excessive heat, moisture, and direct sunlight. Avoid placing them near corrosive substances or in environments that could potentially damage the insulation material. Utilize cases or storage solutions specifically designed for power tools to provide added protection.

Follow Manufacturer Guidelines

Always refer to the manufacturer’s guidelines for information on maintenance and care specific to your power tool. Manufacturers provide detailed instructions on how to clean, inspect, and store their products to ensure proper insulation maintenance. These guidelines are designed to maximize the lifespan and safety of your power tools.

By following these simple maintenance practices, you can ensure that your power tools remain properly insulated, minimizing the risk of electrical accidents during use. Take care of your tools, and they will take care of you.

Key Takeaways: Are Power Tools Insulated?

- Insulation in power tools helps protect users from electric shocks.

- Insulated power tools have a special coating or material that prevents electrical conduction.

- Always check for proper insulation before using power tools.

- Insulated power tools are essential for working in wet or damp conditions.

- Using insulated power tools reduces the risk of accidents and electrical injuries.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section. Here, we will address some common inquiries about power tools and insulation. Read on to learn more.

How important is insulation in power tools?

Insulation plays a crucial role in power tools. Not only does it protect users from electric shocks, but it also prevents electrical leakage. Insulation acts as a barrier between the conductive parts of a power tool and the user handling it. Without proper insulation, the risk of electrical accidents significantly increases.

By ensuring that power tools are properly insulated, manufacturers prioritize user safety. Insulation minimizes the chance of electric shocks and provides an extra layer of protection against potentially dangerous electrical currents. Always choose power tools with adequate insulation for your own safety.

How can I tell if a power tool is insulated?

Identifying whether a power tool is insulated is important for your safety. One way to determine if a power tool is insulated is to look for certifications or safety labels. These certifications indicate that the tool has undergone proper testing and meets safety requirements.

Another way to check if a power tool is insulated is to examine its construction. Insulated power tools often feature a layer of rubber or other insulating materials on the handle or grip. This provides an additional level of protection against electric shocks. Remember to read the manufacturer’s specifications and safety information to ensure the tool is properly insulated.

Are all power tools insulated?

No, not all power tools are insulated. While many modern power tools prioritize insulation for user safety, it is essential to check the specifications and safety features of each tool individually. Some power tools may have specific safety measures, such as double insulation or grounding systems, while others may not have any insulation at all.

When purchasing power tools, always prioritize safety and choose models with appropriate insulation. Inquire about the insulation ratings and certifications before making a purchase. It is crucial to be aware of the safety features of the power tools you are using to prevent potential electrical hazards.

Can I use non-insulated power tools?

Using non-insulated power tools is not recommended, as it poses a significant risk to your safety. Without proper insulation, there is a higher chance of electrical accidents, such as electric shocks or burns. The human body conducts electricity, and direct contact with uninsulated power tools can be extremely dangerous.

It is important to prioritize safety and follow best practices while using power tools. Always choose tools that are properly insulated and meet safety regulations. Insulated power tools provide an extra layer of protection and minimize the risk of electrical accidents, ensuring a safer working environment.

What precautions should I take while using power tools?

While using power tools, it is crucial to follow some precautions to ensure your safety. First, always wear appropriate personal protective equipment (PPE), such as safety goggles, gloves, and non-conductive footwear. This will provide an additional layer of protection during tool operation.

Secondly, make sure you have a good understanding of the tool’s user manual. Familiarize yourself with the safety instructions, recommended usage, and maintenance guidelines. It is also essential to inspect power cords for any signs of damage and to use a residual current device (RCD) for added electrical protection. Lastly, never use power tools in wet or damp conditions, as this significantly increases the risk of electrical hazards.

Every Insulated Tool Electricians Need!!!

Summary

Power tools, like drills and saws, do not have built-in insulation to protect against electric shocks. It is important to use caution and wear protective gear when using these tools to avoid accidents. Insulated gloves can be used to provide extra protection. It is also essential to handle power tools with dry hands and avoid using them around water or damp environments.

Key Points

– Power tools are not insulated, so they can conduct electricity and cause shocks.

– Be careful when using power tools and always wear protective gear.

– Use insulated gloves and handle power tools with dry hands.

– Avoid using power tools around water or wet areas to reduce the risk of accidents.