If you’ve ever wondered what happens to those massive machines that dig tunnels, you’re in the right place. Today, we’re going to explore the fascinating world of tunnel boring machines (TBMs) and find out if they can be reused. So, are tunnel boring machines reused? Let’s dive in and discover the answer!

TBMs are incredible pieces of engineering that revolutionize underground construction. These impressive machines are essentially colossal drills, digging through soil and rock to create tunnels for various purposes. But what happens to them once the tunnel is completed? Are they discarded or given a second lease of life? Stick around to find out!

The world of tunnel boring machines is one of ingenuity and sustainability. Discovering whether these incredible machines can be reused takes us on a journey filled with innovation, cost-saving strategies, and the drive to minimize environmental impact. So, let’s explore the exciting world of TBM reuse and see how these remarkable machines are making a difference in the world of tunneling!

Are Tunnel Boring Machines Reused? The Surprising Truth Revealed

When it comes to major construction projects, tunnel boring machines (TBMs) play a vital role in excavating tunnels quickly and efficiently. These massive machines, also known as moles, have revolutionized the way tunnels are constructed. But the question that often arises is whether tunnel boring machines are reused. In this in-depth article, we will explore the fascinating world of TBMs and uncover the truth behind their reuse.

The Lifecycle of Tunnel Boring Machines

Before delving into the reuse of tunnel boring machines, it is crucial to understand their lifecycle. TBMs are not merely one-time use machines that end up as scrap metal after completing a tunnel. These complex machines go through a series of stages, starting from manufacturing to transport, tunnel excavation, and ultimately, decommissioning. Let’s take a closer look at each stage.

Manufacturing

The manufacturing of tunnel boring machines involves intricate engineering and precision. Each TBM is custom-built to suit the specific tunnel requirements, taking into account factors such as diameter, geology, and project timeline. The manufacturing process requires extensive planning, design, and collaboration between engineers, manufacturers, and project stakeholders. Once completed, the TBM is transported to the construction site.

During the manufacturing stage, certain components of the tunnel boring machine can be reused. For instance, parts such as cutterheads, motors, gearboxes, and control systems can be refurbished and used in future TBMs. This practice not only reduces costs but also contributes to sustainability and resource conservation.

Tunnel Excavation

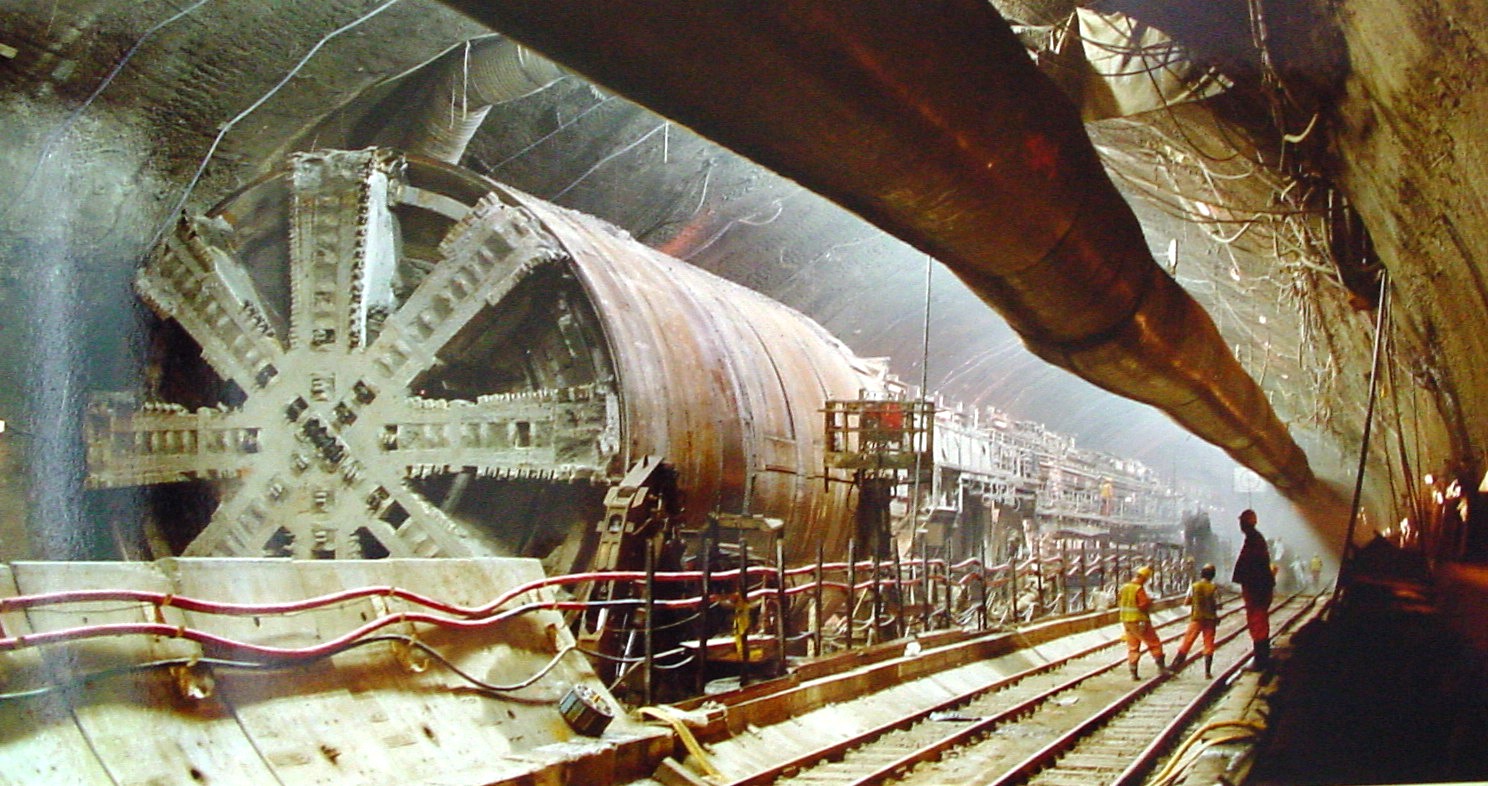

Once the tunnel boring machine arrives at the construction site, it is assembled and launched into the tunnel. The excavation process begins, and the TBM steadily advances, cutting through soil, rock, or other geological formations with its rotating cutterhead. The excavated material, known as spoil, is transported out of the tunnel using a conveyor system or by rail.

Throughout the tunnel excavation phase, the tunnel boring machine undergoes continuous maintenance and repairs to ensure optimal performance. Various components may need replacement or adjustment to address wear and tear. However, most of these components can still be reused in subsequent projects, contributing to the cost efficiency and sustainability of tunneling operations.

Decommissioning and Recycling

Once the tunnel project is completed, and the tunnel boring machine has fulfilled its purpose, it is time for decommissioning. The TBM is disassembled and removed from the tunnel in sections. The reusable components, as well as those that can be salvaged, are carefully identified and preserved for potential future use.

While certain components of the TBM can be reused, it is important to note that the main body or main bearing of the machine is often worn down due to the extensive tunnel excavation process. As a result, these components are typically recycled or repurposed for other applications in the construction industry. The recycling of TBM components and materials ensures the responsible use of resources and minimizes waste.

Benefits of Reusing Tunnel Boring Machines

The reuse of tunnel boring machines offers several significant benefits to the construction industry and the environment. Let’s explore some of the key advantages below:

Cost Efficiency

Reusing TBM components reduces the manufacturing costs of new machines. By refurbishing and implementing previously used parts, construction companies can save a substantial amount of money. Additionally, the cost of transporting and assembling TBMs is significantly reduced when certain components can be reused. This cost efficiency contributes to the overall viability of large-scale tunneling projects.

Sustainability

Tunnel boring machines are known for their immense size and complex construction. Manufacturing new TBMs requires a significant amount of resources, including raw materials and energy. By reusing components, the demand for new manufacturing is reduced, lowering the carbon footprint associated with the production process. Furthermore, the recycling of TBM materials ensures that they do not end up in landfills, minimizing environmental impact.

Innovation and Technological Advancements

Reusing TBM components also offers an opportunity for innovation and technological advancements. As engineers gain insights from previous projects and the performance of reused components, they can refine designs, introduce improvements, and optimize the overall functionality of future tunnel boring machines. This iterative process fosters continuous development and ensures that each new generation of TBMs incorporates the latest advancements in technology and engineering.

The Future of Tunnel Boring Machines

As the construction industry continues to evolve, the reuse of tunnel boring machines is expected to become more prevalent. The emphasis on sustainability, cost-efficiency, and technological advancements necessitates the exploration of creative solutions to meet the growing demand for tunnels worldwide. Reusing TBM components aligns with these goals and offers a promising path forward for the construction industry.

Embracing a Circular Economy

The reuse of tunnel boring machines exemplifies the principles of a circular economy, where resources are reused and recycled, minimizing waste and environmental impact. By incorporating sustainable practices throughout the lifecycle of TBMs, the construction industry can contribute to a more eco-friendly future without compromising on efficiency and innovation. So, the next time you marvel at a tunnel that seemingly appeared out of nowhere, remember that behind its creation lies a fascinating world of reused tunnel boring machines.

Key Takeaways: Are Tunnel Boring Machines Reused?

- Tunnel boring machines (TBMs) are often reused after completing a tunnel project.

- Reusing TBMs helps save costs and reduce environmental impact.

- Before reuse, TBMs undergo thorough inspection and refurbishment.

- Reused TBMs are modified and upgraded to meet specific project requirements.

- Reusing TBMs promotes sustainability in tunnel construction.

Frequently Asked Questions

Welcome to our FAQ section, where we will answer some common questions about tunnel boring machines and their reuse. Read on to learn more!

1. How are tunnel boring machines reused?

Tunnel boring machines, or TBMs, can be reused in a few different ways. After completing a tunneling project, TBMs are often disassembled and transported to another location to begin a new project. This allows companies to save money on purchasing new machines for each project. Additionally, individual components of a TBM, such as the cutterhead and shield, can be refurbished and used again in future machines. Recycling and repurposing of materials is also becoming more common, ensuring that as much of the TBM as possible is given a second life.

It’s worth noting that the reuse of TBMs depends on factors such as the condition of the machine after the previous project and the requirements of the new project. If the machine is too damaged or outdated, it may not be suitable for reuse. Nonetheless, the goal is to maximize the lifespan of tunnel boring machines and minimize waste.

2. Are all tunnel boring machines reusable?

While the reuse of tunnel boring machines is common, it’s not always feasible for all machines. Some TBMs are designed for specific projects and may not be suitable for reuse due to factors such as size, capacity, or specialized features. These machines are often dismantled, and salvageable parts are reused or recycled. However, modern TBMs are designed with reuse in mind, allowing for easier disassembly, transportation, and reassembly.

Furthermore, advances in technology and engineering are constantly improving the reusability of TBMs. Manufacturers are developing modular designs that make it easier to replace or upgrade specific components, increasing the lifespan of the machines. This not only reduces costs but also minimizes the environmental impact of tunneling projects.

3. What are the benefits of reusing tunnel boring machines?

Reusing tunnel boring machines offers several benefits. First and foremost, it reduces the need for new machine manufacturing, saving both resources and energy. This is particularly important considering the massive size and complexity of TBMs. By reusing them, we reduce the environmental impact associated with their production and disposal.

Additionally, reusing TBMs can save money for construction companies. Purchasing new machines for every project can be costly, whereas reusing existing machines lowers the overall expenses. This cost-effectiveness allows companies to invest their resources in other aspects of the project and potentially offer more competitive bids. Finally, reusing TBMs contributes to a more sustainable approach to construction, promoting a circular economy where materials and resources are utilized to their fullest potential.

4. How do companies ensure the safety of reused tunnel boring machines?

Ensuring the safety of reused tunnel boring machines is a top priority for companies. Before a TBM is reused, it undergoes a thorough inspection to assess its condition. Highly trained technicians and engineers check the machine’s components and integrity to identify any potential safety concerns. This includes evaluating the structural integrity, functionality of key systems, and any necessary repairs or maintenance that may be required. If any issues are found, they are addressed before the machine is approved for reuse.

Furthermore, ongoing monitoring and maintenance practices are implemented during the reuse process to ensure that the machine continues to operate safely throughout its lifespan. Regular inspections, maintenance routines, and performance evaluations help identify any emerging issues and address them promptly. By prioritizing safety at every step, companies can confidently reuse tunnel boring machines while maintaining the highest standards of safety.

5. What is the future of tunnel boring machine reuse?

The future of tunnel boring machine reuse looks promising. As construction practices evolve and sustainability becomes increasingly important, companies are investing in research and development to enhance the reusability of TBMs. This includes designing machines that are easier to disassemble, transport, and reassemble, as well as developing innovative techniques for refurbishing and recycling TBM components.

Moreover, there is a growing emphasis on collaboration and knowledge sharing within the construction industry. Lessons learned from previous projects are used to improve future ones, including the reuse of TBMs. As more data and experience are accumulated, companies are better equipped to optimize the reuse process, extending the lifespan of these machines and reducing waste. With these advancements, we can expect to see even more efficient and sustainable reuse of tunnel boring machines in the years to come.

Summary

Tunnel boring machines (TBMs) can be reused, but it depends on the specific circumstances. If the tunnel is of similar size and alignment, the TBM can be dismantled, moved, and used again. However, if the new tunnel has different dimensions or requires advanced technology, a new TBM is usually needed. TBMs are expensive and complex machines, so reusing them can save time and money.

When deciding whether to reuse a TBM, engineers consider factors such as the cost of dismantling and transporting the machine, the condition of the TBM after use, and the suitability of the machine for the new project. While reusing TBMs is beneficial, it is not always possible or practical. Each project is unique, and engineers must carefully evaluate whether reusing a TBM is the right choice.