Have you ever wondered if a bandsaw blade can be put on backwards? Well, you’ve come to the right place to find out! In this article, we’ll explore the intriguing question of whether it’s possible to install a bandsaw blade in reverse. So sit back, relax, and let’s dive into the fascinating world of bandsaw blades!

If you’re a woodworking enthusiast or just starting out, you may have heard rumors about the possibility of putting a bandsaw blade on backwards. But is it true? Can you actually do that? We’ll unveil the answer to this puzzling question and shed light on why it matters. So, get ready to unravel the mystery and get a clearer picture of how bandsaw blades work.

Are you ready for a dose of bandsaw knowledge? Brace yourself as we embark on an exciting journey to uncover the truth behind whether a bandsaw blade can be put on backwards. Join us as we delve into the specifics and discover the importance of the right blade orientation for optimal performance. Let’s get started!

Putting a bandsaw blade on backwards is not recommended. A bandsaw blade is designed with teeth that are angled in a specific direction to ensure proper cutting. If you were to put the blade on backwards, it would not cut effectively and could potentially be dangerous. Always make sure to install the bandsaw blade correctly, following the manufacturer’s instructions.

Can a Bandsaw Blade be Put on Backwards?

In the world of woodworking, bandsaws are essential tools that allow craftsmen to make precise and intricate cuts. A crucial component of the bandsaw is the blade, and it is important to understand how to properly install and use it. One question that often arises is whether a bandsaw blade can be put on backwards. In this article, we will explore this topic in detail and provide you with all the information you need to know.

Understanding Bandsaw Blades

Before we delve into whether a bandsaw blade can be installed backwards, let’s first understand the anatomy of a bandsaw blade. Bandsaw blades typically consist of a continuous loop of steel with teeth along one edge. The teeth are designed to cut through wood, metal, or other materials as the blade moves in a vertical or horizontal motion. The blade is attached to the bandsaw machine and is tensioned to ensure proper cutting performance.

When installing a bandsaw blade, it is important to note that the teeth must face in the correct direction. The teeth should always face forward, or towards the front of the machine, as this is the cutting edge of the blade. Installing the blade backwards can negatively impact its cutting performance and potentially damage the bandsaw.

Additionally, bandsaw blades are often designed with a specific tooth pattern and set. The tooth pattern refers to the spacing and geometry of the teeth, while the set refers to the angle at which the teeth are bent to the left and right. Installing the blade backwards could disrupt the intended tooth pattern and set, resulting in subpar cutting performance.

The Consequences of Installing a Bandsaw Blade Backwards

Now that we understand the importance of installing a bandsaw blade correctly, let’s explore the potential consequences of installing it backwards. When a bandsaw blade is installed backwards, the teeth are facing towards the rear of the machine. This can lead to various issues:

- Poor cutting performance: The teeth are designed to cut efficiently in the forward direction. By installing the blade backwards, the teeth will not engage with the material properly, resulting in a slower and less effective cutting process.

- Increased risk of accidents: Installing the blade backwards can cause the material being cut to get caught or snag on the teeth, potentially causing kickback or other accidents. This not only puts the user at risk but can also damage the bandsaw or the workpiece.

- Dulling of teeth: The cutting edge of the teeth can become dulled or even damaged when the blade is installed backwards. This can result in a shorter blade lifespan and increased maintenance costs.

Overall, installing a bandsaw blade backwards is not recommended and can lead to a range of negative consequences. It is always best to ensure that the teeth are facing forward to achieve optimal cutting performance and maintain safety.

Proper Installation of a Bandsaw Blade

To avoid the issues mentioned above, let’s go over the proper installation process for a bandsaw blade:

- Disconnect the power: Before installing or removing a bandsaw blade, make sure the machine is turned off and unplugged. This is crucial for your safety.

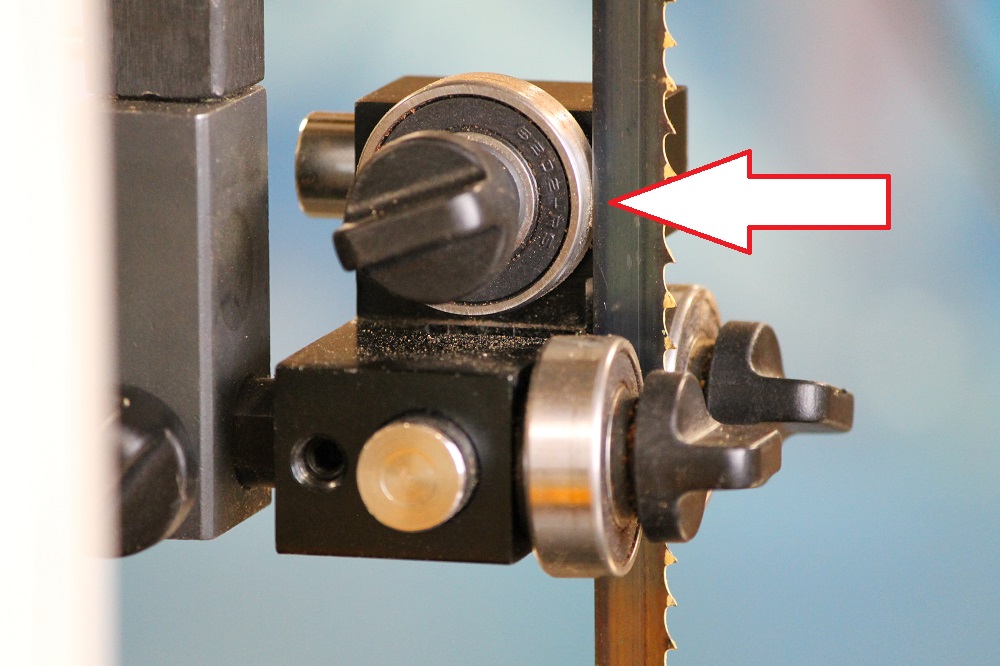

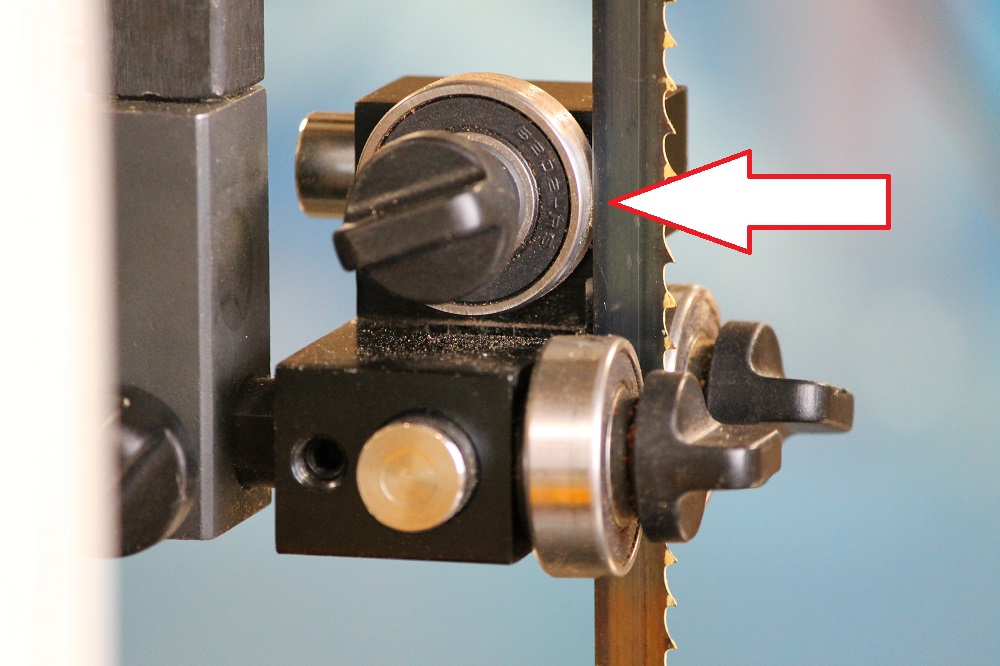

- Release the tension: Loosen the tension on the blade by adjusting the tension knob or lever. This will make it easier to install or remove the blade.

- Install the blade: Align the teeth of the blade with the bandsaw’s drive wheels, making sure they face forward. Carefully guide the blade onto the wheels, ensuring that it sits properly in the blade guides and is aligned with the tracking system.

- Apply tension: Gradually increase the tension on the blade by tightening the tension knob or lever. This will ensure that the blade is properly tensioned for optimal cutting performance.

- Check tracking and blade guides: Verify that the blade is running smoothly and centered on the wheels. Adjust the tracking if necessary and ensure that the blade guides are properly aligned to support the blade.

By following these steps, you can confidently install a bandsaw blade correctly and avoid the pitfalls of installing it backwards.

Common Bandsaw Blade Installation Mistakes

Aside from installing a bandsaw blade backwards, there are a few other common mistakes that woodworkers make when installing blades. Let’s take a look at them:

Using the Wrong Blade Width

Each bandsaw is designed to accommodate blades of a specific width. It is important to select a blade that matches the width capacity of your particular bandsaw. Using a blade that is too wide can cause binding and damage to the machine, while a blade that is too narrow may not provide sufficient stability during cutting.

Poor Blade Tensioning

Proper blade tension is crucial for achieving optimal cutting performance and preventing blade breakage. Some woodworkers tend to under-tension or over-tension the blade, leading to subpar results. It is important to follow the manufacturer’s guidelines and adjust the tension accordingly.

Incorrect Blade Tracking

Blade tracking refers to the alignment of the blade on the bandsaw’s wheels. If the blade is not properly tracked, it can lead to uneven wear, premature blade breakage, and poor cutting performance. Regularly check the blade tracking and make adjustments as needed.

Lack of Blade Maintenance

Proper maintenance is key to prolonging the lifespan of a bandsaw blade. Neglecting to clean, lubricate, and occasionally sharpen the blade can result in dullness, poor cutting performance, and a shorter lifespan. Develop a cleaning and maintenance routine to keep your bandsaw blade in top condition.

Using the Wrong Blade TPI (Teeth per Inch)

The TPI of a blade refers to the number of teeth it has per inch. Different TPIs are suitable for different cutting applications. Using a blade with the wrong TPI can result in rough cuts, excessive heat, or even damage to the workpiece and bandsaw. Select the appropriate TPI for your specific cutting needs.

Choosing the Wrong Blade Type

Bandsaw blades come in various types, including regular tooth, hook tooth, skip tooth, and variable tooth. Each type is designed for specific cutting tasks and materials. Choosing the wrong blade type can lead to poor cutting performance and reduced accuracy. Determine the appropriate blade type based on the materials you commonly work with.

FAQs About Bandsaw Blades

Now, let’s address some frequently asked questions about bandsaw blades:

Can I sharpen a dull bandsaw blade?

Yes, it is possible to sharpen a dull bandsaw blade. However, sharpening a blade requires skill and the proper equipment. If you are not experienced in blade sharpening, it is advisable to seek professional assistance. Alternatively, you can replace the blade with a new one.

How long does a bandsaw blade last?

The lifespan of a bandsaw blade depends on various factors, including the frequency of use, the type of materials cut, and the maintenance routine. On average, a well-maintained bandsaw blade can last anywhere from several months to a couple of years.

What is the purpose of blade guides?

Blade guides are components of a bandsaw that help support and stabilize the blade during cutting. They minimize blade deflection and ensure accurate and controlled cuts. Blade guides typically consist of two side guides and a thrust bearing at the back of the blade.

Tips for Optimal Bandsaw Blade Performance

Here are some tips to help you achieve optimal performance from your bandsaw blade:

Choose the right blade for the job:

Select a blade that is suitable for the type of cuts you need to make and the materials you are working with.

Maintain proper blade tension:

Make sure to tension the blade correctly to prevent blade breakage and ensure optimal cutting performance.

Keep the blade clean:

Regularly clean the blade to remove sawdust, resin, and other debris that can accumulate during cutting. This will help prevent the blade from becoming dull and reduce the risk of overheating.

Inspect the blade regularly:

Check the blade for signs of wear, damage, or dullness. Replace the blade if necessary to maintain cutting quality and safety.

Adjust the blade guides:

Properly align and adjust the blade guides to ensure that the blade is supported and guided smoothly during cutting.

Final Thoughts

Installing a bandsaw blade backwards can have detrimental effects on cutting performance, safety, and the lifespan of the blade. Therefore, it is important to always install the blade with the teeth facing forward and follow the manufacturer’s guidelines for proper installation and maintenance. By doing so, you can achieve accurate cuts, prolong the life of your bandsaw blade, and ensure the safety of both yourself and your workpiece.

Key Takeaways: Can a Bandsaw Blade Be Put on Backwards?

- Putting a bandsaw blade on backwards can cause reduced cutting performance.

- The teeth of the blade are designed to cut as they move in a particular direction.

- Reversing the blade will result in inefficient cutting and potential damage to the workpiece.

- Always ensure that the teeth of the blade are facing the correct cutting direction.

- If unsure, consult the bandsaw manual or ask an experienced professional for guidance.

Frequently Asked Questions

Are you wondering if it’s possible to put a bandsaw blade on backwards? Look no further! Here are some common questions and answers about this topic.

1. Can I accidentally put a bandsaw blade on backwards?

Yes, it is possible to mistakenly put a bandsaw blade on backwards. Many bandsaw blades are not symmetrical, and they have teeth that are designed to cut in one specific direction. If you install the blade with the teeth facing the wrong way, you may experience poor cutting performance and even damage the blade or the bandsaw itself. It’s essential to pay attention to the blade orientation when installing a bandsaw blade.

2. How can I tell if I’ve put a bandsaw blade on backwards?

There are a few ways to determine if you’ve put a bandsaw blade on backwards. First, check the teeth of the blade. The teeth should be pointing downward towards the table or workpiece. If the teeth are facing upwards, this indicates that the blade is on backwards. Additionally, you may notice that the blade is not cutting smoothly or that it is making excessive noise. These are also signs that the blade may be installed incorrectly.

3. What problems can occur if a bandsaw blade is installed backwards?

If a bandsaw blade is installed backwards, it can lead to several issues. The primary problem is poor cutting performance. The blade may struggle to cut through the material, resulting in rough cuts and jagged edges. Additionally, an improperly installed blade can cause excessive vibrations and noise, potentially damaging the blade or the bandsaw itself. It’s important to install the bandsaw blade correctly to ensure optimal performance and longevity.

4. How do I avoid putting a bandsaw blade on backwards?

To avoid putting a bandsaw blade on backwards, follow these simple steps. First, identify the teeth of the blade and determine which side should face down towards the table or workpiece. Then, loosen the blade tension by turning the tension knob counterclockwise. Carefully slide the blade into place, aligning the teeth correctly. Finally, increase the tension by turning the knob clockwise until the blade is securely in place. Double-check the blade orientation before turning on the saw.

5. Can reversing a bandsaw blade fix the issue if it’s installed backwards?

No, reversing a bandsaw blade will not fix the issue if it’s installed backwards. The teeth on the blade are specifically designed for cutting in one direction, and flipping the blade will not change this. If you’ve installed the blade incorrectly, the best course of action is to remove it and reinstall it with the teeth facing the correct way. Make sure to follow the manufacturer’s instructions and take the necessary precautions to ensure safe and accurate cutting.

Summary:

Putting a bandsaw blade on backward is a bad idea! It won’t cut properly and can be dangerous. Bandsaw blades have teeth that are designed to cut in one direction, so if you put the blade on backwards, it won’t work right. Always make sure to install the bandsaw blade correctly with the teeth facing the right way to ensure safe and effective cutting.