Can a bandsaw cut hardened steel? If you’re a curious DIYer or just looking to expand your knowledge about metalworking, you’ve come to the right place! In this article, we’ll explore the fascinating world of bandsaws and their capabilities when it comes to cutting through hardened steel. So, fasten your seatbelt and get ready for an exciting adventure into the realm of metal cutting!

When it comes to slicing and dicing metal, the bandsaw has long been a reliable tool for both professionals and hobbyists alike. But can it handle the tough challenge of cutting through hardened steel? That’s the burning question we’ll be answering today. Whether you’re cutting bars, rods, or sheets of hardened steel, we’ll dive into the capabilities, limitations, and best practices for using a bandsaw in this demanding task.

So, if you’ve ever wondered whether you need a specialty tool like a metal-cutting bandsaw or if a regular one will do the trick, you’re about to find out. By the end of this article, you’ll have a good understanding of what it takes to cut through hardened steel and whether a bandsaw is up to the challenge. Ready? Let’s get started on this epic metal-cutting journey!

Bandsaws are versatile tools, but can they handle hardened steel? Let’s find out! While bandsaws are excellent for cutting through various materials, cutting hardened steel may not be their strong suit. Hardened steel is extremely tough, requiring specialized tools like carbide-tipped blades or abrasive discs for efficient cutting. However, some bandsaws with high horsepower and high-quality blades can make limited cuts on hardened steel. It’s important to consult the bandsaw manufacturer’s guidelines and choose the appropriate blade for the task at hand.

Can a Bandsaw Cut Hardened Steel?

When it comes to cutting hardened steel, a bandsaw is a popular tool of choice for many professionals. With its versatile blade and powerful motor, a bandsaw can make clean and precise cuts through a wide range of materials. However, cutting hardened steel requires more than just the right tool. In this article, we will explore the capabilities of a bandsaw when it comes to cutting hardened steel, the factors that affect its performance, and some tips to achieve the best results.

The Basics of Bandsaw Cutting

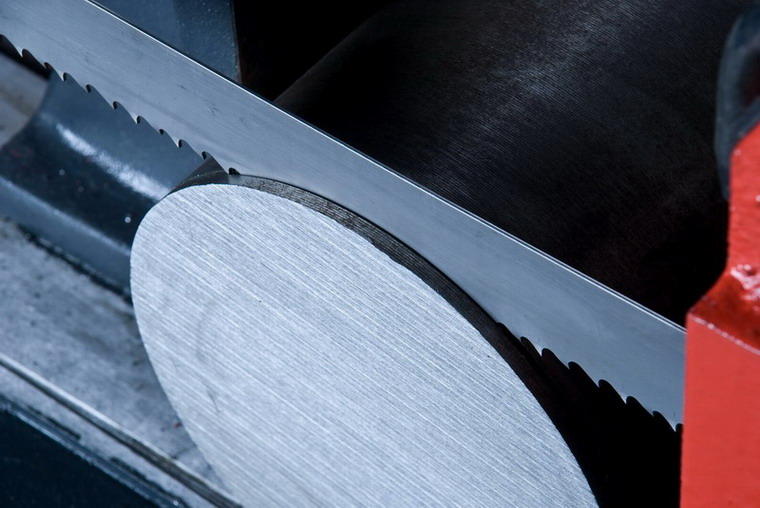

A bandsaw is a power tool consisting of a continuous looped blade that is stretched between two wheels. The blade moves in a vertical motion, allowing for straight and curved cuts in various materials. The teeth of the blade are designed to remove the material as it passes through, leaving a clean and smooth cut.

When it comes to cutting hardened steel, the hardness of the material poses a challenge. Hardened steel is known for its resistance to cutting and its ability to dull blades quickly. However, with the right blade and proper techniques, a bandsaw can still be effective in cutting through this tough material.

The Factors Affecting Bandsaw Cutting Performance on Hardened Steel

There are several factors that can affect the performance of a bandsaw when cutting hardened steel:

- Blade Selection: Choosing the right blade for cutting hardened steel is crucial. Bandsaw blades come in different materials, tooth configurations, and sizes. For cutting hardened steel, bi-metal blades with carbide-tipped teeth are recommended for their excellent durability and cutting performance.

- Blade Speed: The speed at which the blade moves is another important factor. Cutting hardened steel requires slower blade speeds to prevent overheating and premature blade wear. Consult the manufacturer’s recommendations for the optimal speed for cutting hardened steel.

- Blade Tension: Proper blade tension is key to achieving clean cuts. Insufficient tension can cause the blade to wander and produce uneven cuts, while excessive tension can lead to blade breakage. Follow the manufacturer’s guidelines for tensioning the blade.

- Lubrication: Lubrication plays a crucial role in reducing friction and heat during cutting. Applying a cutting fluid or lubricant to the blade and the material helps to prolong blade life and improve cutting performance. Select a lubricant specifically designed for cutting hardened steel.

- Feed Rate: The rate at which the material is fed into the blade affects the cutting performance. Feeding the material too fast can cause the blade to bind or break, while feeding too slowly can cause excessive heat buildup. Find the right feed rate for cutting hardened steel through experimentation and practice.

Tips for Achieving the Best Results

To achieve the best results when cutting hardened steel with a bandsaw, consider the following tips:

- Use a sturdy and stable work surface to ensure precise cuts and reduce vibrations.

- Secure the material firmly using clamps or a vise to prevent movement during cutting.

- Wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

- Start with a slow blade speed and adjust if necessary, paying attention to the color of the chips for signs of overheating.

- Monitor the blade for signs of wear, such as dullness or chipping, and replace it when necessary.

- Clean the blade and remove any debris or buildup to prevent blade damage.

The Bottom Line: Bandsaw Cutting of Hardened Steel

While a bandsaw can indeed cut hardened steel, it is important to choose the right blade, set the correct parameters (blade speed, tension, lubrication, and feed rate), and follow safety guidelines for optimal performance. Cutting hardened steel is a challenging task that requires precision and care. With the right approach, a bandsaw can be a valuable tool in your arsenal for tackling this difficult material.

Can a Bandsaw Cut Hardened Steel?

- While bandsaws are primarily used for cutting wood, they can also cut through hardened steel.

- When cutting hardened steel, it is important to choose the right blade with a high tooth count and suitable hardness.

- Cutting hardened steel with a bandsaw requires slow and steady feed rates to avoid damaging the blade or workpiece.

- Using a coolant or lubricant can greatly improve the cutting performance and prolong the life of the blade.

- It’s crucial to use appropriate safety measures like wearing protective gear and ensuring the workpiece is securely clamped during the cutting process.

Frequently Asked Questions

Interested to know if a bandsaw can cut hardened steel? Here are some commonly asked questions about the topic:

1. How effective is a bandsaw at cutting hardened steel?

Bandsaws can be effective for cutting hardened steel if equipped with the right blade and operating parameters. The key is to use a bi-metal blade specifically designed for cutting hard materials. The teeth of this blade are constructed from high-speed steel or a similar hard material, while the body remains flexible. This combination allows the blade to maintain sharpness while withstanding the rigidity of hardened steel.

Additionally, to achieve optimal cutting results, it is important to adjust the bandsaw’s speed and feed rate according to the hardness of the steel being cut. By using the appropriate blade and setting the bandsaw correctly, you can achieve precise cuts in hardened steel.

2. What factors affect the bandsaw’s ability to cut hardened steel?

Several factors can affect the bandsaw’s ability to cut hardened steel effectively. Firstly, the type and quality of the blade are crucial. Using a bi-metal blade with hardened teeth is essential to withstand the hardness of the steel. Additionally, selecting a blade with the appropriate tooth pitch is important to optimize cutting efficiency.

Another crucial factor is the speed and feed rate at which the bandsaw is operated. Cutting hardened steel requires slower speeds and higher feed rates to prevent overheating and prolong blade life. Finally, maintaining proper blade tension throughout the cutting process ensures accurate and efficient cutting results.

3. Can a bandsaw cut through any type of hardened steel?

A bandsaw is capable of cutting through a wide range of hardened steels, including tool steel, stainless steel, and alloy steel. However, the hardness level and thickness of the steel can impact the cutting performance. Bandsaws are particularly effective in cutting steels with a hardness up to 45-50 HRC (Rockwell hardness scale).

For extremely hard steels beyond this range, other cutting methods like abrasive cutting or waterjet cutting might be more suitable. It is essential to consider the specific properties and hardness of the steel before deciding on the best cutting method.

4. Is it necessary to use coolant when cutting hardened steel with a bandsaw?

Using coolant while cutting hardened steel with a bandsaw is highly recommended. Coolant helps to lubricate the cutting process, reducing friction and heat buildup. This, in turn, extends blade life and improves cutting efficiency. Coolant also helps to flush away chips and prevent them from clogging the blade, resulting in smoother cuts.

There are different types of coolants available, such as soluble oil or synthetic fluids. Selecting the appropriate coolant for the specific steel being cut is important to achieve the desired cutting results. Always follow the manufacturer’s guidelines and recommendations when using coolant with your bandsaw.

5. Can a bandsaw be used for both straight and curved cuts in hardened steel?

Yes, a bandsaw can be used for both straight and curved cuts in hardened steel. The bandsaw’s blade can be adjusted according to the required cutting angle, allowing for precise and accurate cuts. It is important to use the appropriate blade with the right tooth pitch and tension to achieve the desired results.

For curved cuts, utilizing a blade with a smaller width and higher teeth per inch (TPI) allows for greater maneuverability and smoother cuts. Ensure proper setup and blade tracking to maintain control and accuracy throughout the cutting process.

Summary

So, can a bandsaw cut hardened steel? The answer is yes, but it depends on a few things. First, you’ll need the right type of bandsaw with a powerful motor and the correct blade. Second, you’ll need to take your time and use a slow cutting speed. And finally, you’ll need to take breaks to allow the blade to cool down. If you follow these guidelines, you can successfully cut hardened steel with a bandsaw.

However, it’s important to remember that cutting hardened steel can be challenging and requires experience and caution. If you’re a beginner, it’s best to seek guidance or assistance from an experienced professional. Always prioritize safety when working with power tools and follow the manufacturer’s instructions. Happy cutting!