If you’ve ever wondered, “Can a lathe be repaired?” Well, you’re in the right place! Lathes are incredibly useful machines but, like anything else, they can break down over time. But fear not, because in this article, we’re going to explore whether a lathe can be repaired and what you can do if yours is in need of some TLC.

So, let’s dive right in. The short answer to the question “Can a lathe be repaired?” is a resounding yes! Lathes are complex machines, but they are designed to be repaired and maintained. Whether it’s a small issue like a worn-out belt or a more serious problem with the motor, there is usually a solution to get your lathe up and running again.

But before we get into the details of lathe repairs, it’s essential to understand the importance of regular maintenance. Just like a car needs oil changes and tune-ups, a lathe requires routine care to keep it in top shape. By following proper maintenance practices, you can minimize the chances of a breakdown and prolong the lifespan of your lathe.

So, if you’re ready to learn more about lathe repairs, grab your toolbox and let’s explore the wonderful world of fixing and maintaining lathes! Whether you’re a seasoned lathe operator or a curious beginner, this article will provide you with valuable insights and practical tips to keep your lathe in tip-top condition. Let’s get started!

Wondering if a lathe can be repaired? Absolutely! Lathes are durable machines that can be fixed when issues arise. Whether it’s a motor problem, a damaged tool rest, or a faulty spindle, a skilled technician can diagnose and repair the lathe. If you’re facing any issues with your lathe, reach out to a professional for a thorough assessment and necessary repairs. Don’t worry, your lathe can be back up and running smoothly in no time!

Can a Lathe Be Repaired?

Introduction: Lathes are essential tools in many industries, used for cutting, shaping, and drilling various materials. Over time, these machines can experience wear and tear, leading to performance issues. The question arises: can a lathe be repaired? In this article, we will explore the possibilities of repairing a lathe, the common issues that arise, and the steps you can take to ensure the longevity of your machine.

Understanding Lathe Repair

When it comes to lathe repair, it’s important to understand that a lathe is a complex piece of machinery with various components that work together to perform precision tasks. Repairing a lathe can involve various tasks, from simple maintenance to replacing parts and even rebuilding the machine from scratch. Before jumping into the repair process, it’s crucial to assess the extent of the damage and the feasibility of repairs.

The most commonly encountered issues with lathes include motor failure, belt problems, misalignment, worn-out bearings, and damaged tool rests. Identifying these issues is the first step towards repairing your lathe. Some issues can be resolved with simple repairs, such as replacing a faulty motor or tightening loose belts. However, more severe problems, like a misaligned bed or extensive wear on critical components, may require professional expertise or even the replacement of the entire machine.

Diagnosing and Addressing Lathe Issues

1. Motor Failure: One of the main issues lathe owners face is motor failure. Symptoms may include the lathe not starting, motor stalling or making unusual noises. If you suspect a motor problem, start by checking the power supply. If the power is flowing correctly and the motor still doesn’t work, it’s likely you’ll need to replace it. Consult with a professional to ensure you choose the right motor for your lathe model.

2. Belt Problems: The belts in a lathe can wear out over time, leading to slipping, poor performance, or even complete failure. To address belt issues, start by inspecting for signs of wear and tension. If you notice cracks, fraying, or significant looseness, it’s time to replace the belt. Refer to your lathe’s user manual for guidance on belt replacement and tension adjustments.

3. Misalignment: Misalignment of components, such as the headstock, tailstock, or tool rest, can result in inaccuracies and poor cuts. One way to check for misalignment is by making test cuts and reviewing the results. If you notice inconsistencies, the machine may need realignment. This task requires precision and is often best left to professionals or experienced lathe users.

4. Worn-out Bearings: Bearings play a crucial role in ensuring smooth and accurate motion in a lathe. Over time, they can wear out, causing excessive vibration or limited movement. Replacing bearings is a meticulous task that requires technical knowledge. Consult a lathe technician or refer to your user manual for guidance on bearing replacement.

5. Damaged Tool Rests: The tool rest is essential for holding and guiding cutting tools during lathe operations. If the tool rest is damaged or worn out, it can pose a safety hazard and affect the quality of your work. Replace any damaged tool rests immediately, following the manufacturer’s instructions for installation and adjustment.

Tips for Lathe Maintenance and Longevity

1. Regular Cleaning and Lubrication: Keep your lathe clean by removing dust and debris regularly. Additionally, ensure proper lubrication of moving parts to reduce friction and wear. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

2. Proper Tool Usage: Always use the appropriate tools for your lathe and ensure they are sharp and in good condition. Dull or damaged tools can put strain on the lathe and lead to premature wear and tear.

3. Safe Operation: It’s crucial to follow safety guidelines when operating a lathe to prevent accidents and damage to the machine. Familiarize yourself with the lathe’s safety features and use them consistently.

4. Regular Inspection: Conduct regular inspections of your lathe, paying close attention to signs of wear, loose fittings, or any unusual noises. Early detection of issues can prevent further damage and increase the chances of successful repairs.

5. Professional Help: If you’re unsure about how to address a lathe issue or if the problem seems beyond your capabilities, seek professional assistance. Experienced technicians can diagnose the problem accurately and provide guidance on the necessary repairs.

The Future of Lathe Repair

With advancements in technology, the future of lathe repair holds promise. New techniques and materials are continuously being developed to enhance the durability and ease of maintenance of lathes. Additionally, online resources and communities provide valuable information and support for lathe owners, facilitating DIY repairs and maintenance. As long as lathe owners remain proactive and diligent in their approach to machine care, the longevity of lathes and their repairability can be ensured for years to come.

Conclusion:

Repairing a lathe is possible in many cases, depending on the severity of the issue and the availability of replacement parts. Routine maintenance and proper usage can greatly extend the lifespan of a lathe and reduce the likelihood of major repairs. In instances where repairs are necessary, it’s important to consult professionals or refer to reliable resources to ensure the correct procedures are followed. By taking care of your lathe and promptly addressing any issues, you can enjoy the benefits of a fully functional machine for years to come.

Can a Lathe be Repaired?

- Yes, lathes can be repaired if they encounter mechanical issues.

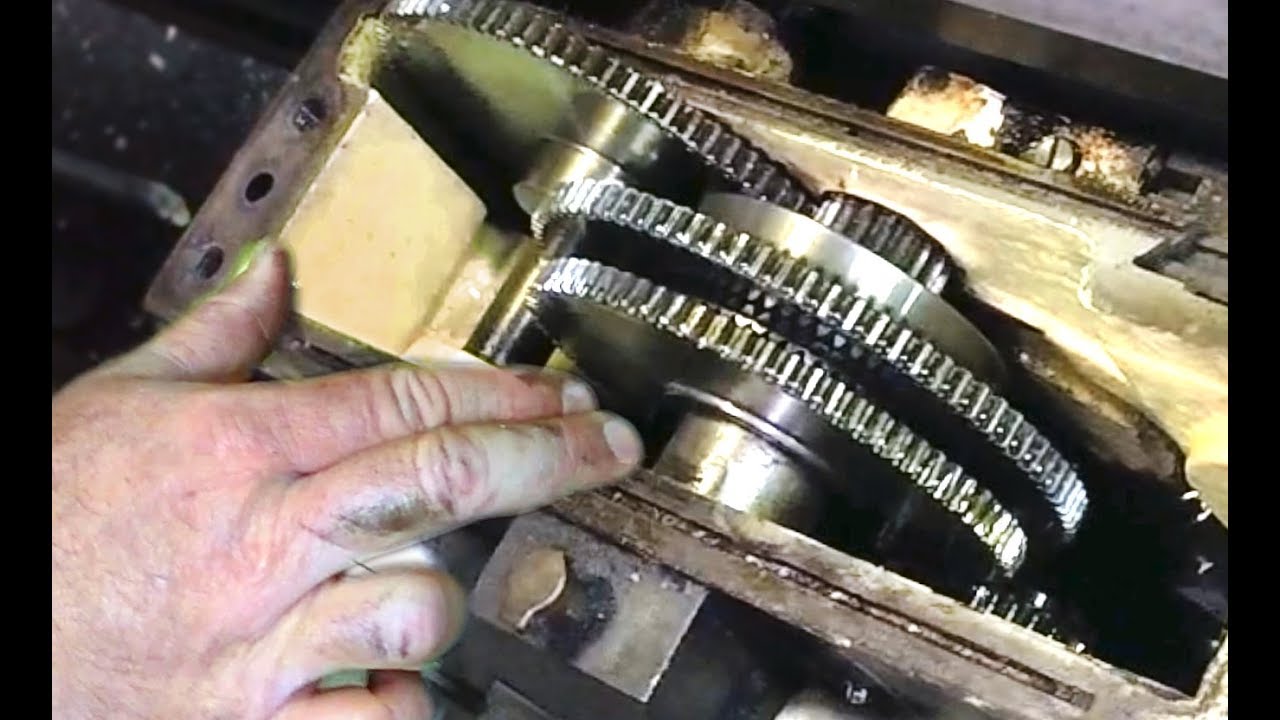

- Common problems with lathes include damaged gears, worn-out belts, or motor malfunctions.

- Repairs may require replacing faulty parts or conducting maintenance procedures.

- It is recommended to seek the assistance of a professional technician for lathe repairs.

- Regular maintenance and proper usage can help prevent the need for extensive repairs.

Frequently Asked Questions

Welcome to our frequently asked questions section. Here, you’ll find answers to common questions about repairing lathes. Whether you’re a beginner or an experienced user, we’ve got you covered. Read on to learn more!

Q1: How do I know if my lathe needs to be repaired?

There are a few signs to look out for that indicate your lathe may need repairs. Firstly, if you notice any unusual noises or vibrations during operation, it could be a sign of a mechanical issue. Additionally, if you’re experiencing inconsistent or poor-quality cuts, it’s worth considering repairs. Another telltale sign is excessive wear on the lathe’s components, such as the tool rest or headstock. If you observe any of these signs, it’s advisable to have your lathe inspected and repaired if necessary.

Remember, regular maintenance and cleaning can help prevent major issues and extend the lifespan of your lathe. So, be sure to keep an eye out for any signs of wear or malfunction and address them promptly.

Q2: Can I repair my lathe myself, or do I need professional help?

While some basic repairs and maintenance tasks can be performed by lathe owners, it’s often advisable to seek professional help for more complex repairs. Repairing a lathe requires knowledge of its intricate mechanisms and specialized tools. Skilled professionals have the experience and expertise to diagnose and fix issues properly, ensuring the lathe operates safely and efficiently.

Attempting repairs on your own without proper knowledge and experience may lead to further damage or even personal injury. So, unless you have the necessary training and expertise, it’s generally recommended to consult a professional lathe repair service for any significant repairs or complex issues.

Q3: What is the typical cost of repairing a lathe?

The cost of repairing a lathe can vary depending on the extent of the damage and the specific repairs needed. Minor repairs such as replacing small parts or addressing minor issues may cost less, typically ranging from $50 to $200. However, if major repairs or replacements of critical components, such as the motor or spindle, are required, the cost can increase significantly, ranging from $500 to $2000 or more.

It’s important to consult with a professional for an accurate assessment of the repairs needed and the associated costs. They can provide a detailed estimate based on the specific condition of your lathe and the required repairs, allowing you to make an informed decision.

Q4: How long does it typically take to repair a lathe?

The duration of lathe repairs can vary depending on the complexity of the issues and the availability of replacement parts. Minor repairs or regular maintenance tasks can often be completed within a few hours or a day. However, major repairs that involve extensive disassembly, replacement of components, or ordering specialized parts may take several days or even weeks to complete.

It’s important to factor in the time required for repairs when planning your projects. If you rely heavily on your lathe for work or hobbies, consider having a backup plan or consulting with the repair professional to determine the estimated timeline for the repairs.

Q5: Are there any preventative measures I can take to avoid extensive lathe repairs?

Yes, there are several preventative measures you can take to minimize the likelihood of extensive lathe repairs. Regular cleaning and maintenance, such as lubricating moving parts and ensuring proper alignment, can help prolong the lifespan of your lathe and prevent minor issues from escalating into major problems.

Additionally, using your lathe correctly and following the manufacturer’s guidelines for operation and maintenance can greatly reduce the risk of damage. Avoid overloading the lathe, using improper cutting techniques, or neglecting routine maintenance. It’s also advisable to schedule periodic inspections by a professional to identify any potential issues before they worsen.

Summary

So, can a lathe be repaired? The answer is yes! If your lathe is experiencing issues, you have options. First, try troubleshooting the problem yourself. If that doesn’t work, reach out to a professional technician who can help fix it. Remember, regular maintenance is key to keep your lathe in good condition and prevent major repairs in the future. Taking care of your lathe will ensure it lasts for a long time and continues to work smoothly. So don’t worry if your lathe breaks down, it can be repaired!