Have you ever wondered if a lathe could make itself? It may sound like a puzzling question, but it actually brings up some fascinating concepts about machines and their capabilities. Let’s dive into this intriguing topic and explore the possibilities together.

Picture this: a lathe is a machine that is used to shape and cut materials, like wood or metal, with precision. But can it go beyond its primary function and actually create a replica of itself? It’s almost like asking if a painter can paint an exact copy of themselves – it sounds mind-boggling, doesn’t it?

When we think about machines, we often assume that they are entirely dependent on human intervention. After all, we design and build them to serve specific purposes. But what if a machine could break free from this reliance and replicate itself? Stick around as we unravel the mysteries behind the question: Can a lathe make itself?

So, let’s embark on this intriguing journey and explore the possibilities that lie within the realm of self-replicating machines. Can a lathe truly create another one of its kind? Let’s find out together!

A lathe cannot make itself, but it plays a crucial role in making various objects. The lathe is a powerful tool used in woodworking and metalworking to shape, cut, and drill materials. It is operated by skilled individuals who utilize its features to create intricate designs and functional pieces. While a lathe is not capable of self-replication, it enables the creation of countless projects and contributes to the craftsmanship of skilled artisans.

Can a Lathe Make Itself? The Truth Behind This Question

When it comes to machines, the concept of self-replication can seem like something out of science fiction. However, the question remains: can a lathe make itself? This intriguing query delves into the realm of possibility and the capabilities of modern technology. In this article, we will explore the mechanics of a lathe, the concept of self-replication in machines, and whether a lathe can truly make itself.

The Basics of a Lathe

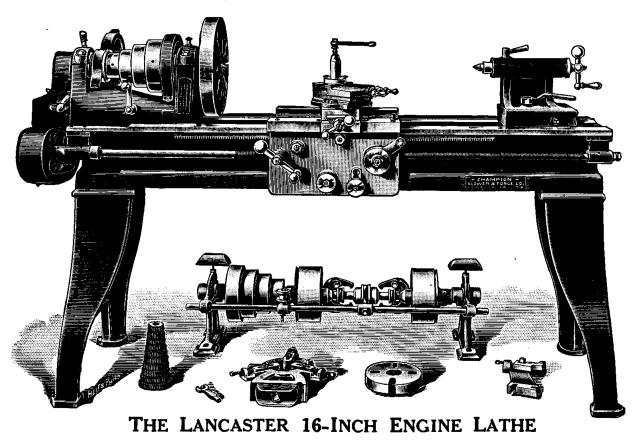

Before we delve into the question at hand, it’s important to understand what a lathe is and how it works. A lathe is a machine tool that rotates a workpiece on its axis and uses various cutting tools to shape, cut, or drill the material. It allows for precision machining and is commonly used in manufacturing, woodworking, and metalworking industries. Whether it’s creating intricate designs on a piece of wood or producing intricate parts for aerospace applications, lathes play a vital role in modern machining.

The basic components of a lathe include the headstock, which holds and rotates the workpiece; the toolpost, which holds the cutting tools; the carriage, which moves the toolpost along the length of the workpiece; and the tailstock, which provides additional support for longer workpieces. These components work together to enable precise and efficient machining.

Now that we have a better understanding of what a lathe is and how it functions, let’s explore the question of whether a lathe can make itself.

Self-Replication in Machines: The Concept

The idea of self-replication in machines, often referred to as machine self-replication or von Neumann self-replication, is rooted in the concept of creating a machine capable of reproducing itself autonomously. This concept was first proposed by mathematician John von Neumann in the 1940s and has since captured the imagination of scientists and engineers.

In theory, a self-replicating machine would be able to build a copy of itself using raw materials and an existing set of instructions or blueprints. This would require the machine to have the ability to manipulate its environment, gather resources, and assemble its own components. While the concept may seem far-fetched, significant progress has been made in the field of self-replicating machines, particularly in the realm of 3D printing and robotics.

However, when it comes to lathes specifically, the ability to self-replicate is currently beyond their capabilities. While a lathe can perform complex machining operations, it requires skilled operators to set up and program the machine. Additionally, the creation and assembly of the various components of a lathe require advanced manufacturing processes that are not yet achievable by the machine itself. Therefore, while the idea of a lathe making itself is intriguing, it remains outside the realm of the possible at present.

The Future of Self-Replicating Machines

While a lathe may not be capable of making itself, the concept of self-replicating machines continues to be an area of active research and development. Scientists and engineers are making significant strides in the field of robotics, nanotechnology, and additive manufacturing, all of which contribute to the advancement of self-replicating machines.

Advances in 3D printing technology, for example, have allowed for the creation of intricate and complex structures with minimal human intervention. With further advancements and improvements in this field, it is conceivable that machines, including lathes, could be designed to print their own components and eventually achieve a level of self-replication.

In conclusion, while a lathe cannot currently make itself due to the complexities involved in its manufacturing and assembly, the field of self-replicating machines holds promise for the future. As technology continues to evolve, it is not inconceivable that we may one day witness the creation of a lathe or other machines capable of autonomous self-replication. Until then, the role of skilled machinists and operators remains crucial in the manufacturing industry.

The Advantages of Lathe Machines

Lathe machines offer a range of advantages that make them indispensable in various industries. Here are some key benefits of using lathe machines:

Precision Machining

One of the primary advantages of lathe machines is their ability to achieve precise and accurate machining. With the right cutting tools and techniques, a lathe can produce intricate details and tight tolerances. This makes lathe machines ideal for applications that require high levels of precision, such as aerospace and medical industries.

Versatility

Lathe machines are highly versatile and can be used for a wide range of applications. Whether it’s turning, facing, drilling, or threading, a lathe machine can perform multiple machining operations. This versatility allows manufacturers to produce a variety of components without the need for different machines, increasing efficiency and reducing costs.

Efficiency and Productivity

Lathe machines are designed for efficiency and productivity. With their ability to automate processes and perform multiple operations in one setup, they can significantly reduce machining time. This means faster production and quicker turnaround times for manufacturers, resulting in increased productivity and cost-effectiveness.

Cost Savings

By combining multiple machining operations into one machine, lathe machines offer cost savings for manufacturers. Instead of investing in multiple machines and the associated maintenance and tooling costs, manufacturers can rely on a single lathe machine to meet their machining needs. This reduces capital expenditure and improves the overall profitability of the business.

Tips for Using Lathe Machines Effectively

While lathe machines offer numerous advantages, it’s essential to use them effectively to maximize their potential. Here are some tips for using lathe machines effectively:

Proper Tool Selection

Choosing the right cutting tools for the material and application is crucial for achieving optimal results. Different materials require specific cutting tools and speeds to ensure efficient and accurate machining. Understanding the properties of the material and selecting appropriate tooling will help prevent damage to the lathe machine and produce high-quality components.

Regular Maintenance and Lubrication

Regular maintenance and lubrication of the lathe machine are essential for its proper functioning and longevity. Following the manufacturer’s recommended maintenance schedule and ensuring proper lubrication of moving parts will prevent premature wear and minimize the risk of breakdowns. This will also contribute to the overall efficiency and accuracy of the machine.

Consider Workholding Options

Choosing the right workholding method is crucial for secure and stable machining. Whether it’s using chucks, collets, or other specialized workholding devices, selecting the appropriate option for the specific application will ensure that the workpiece remains securely in place during machining. This will help prevent errors and defects in the finished component.

Continuous Learning and Skill Development

To effectively operate a lathe machine, continuous learning and skill development are key. Staying updated with the latest machining techniques, tooling advancements, and industry trends will allow operators to efficiently utilize the capabilities of the lathe machine. Training programs, workshops, and online resources are valuable tools for enhancing skills and knowledge in lathe machine operations.

In Conclusion

While a lathe machine cannot currently make itself, the concept of self-replicating machines continues to be an area of active research and development. With advancements in technology, the future holds promising possibilities for machines capable of autonomous self-replication. In the meantime, lathe machines offer numerous advantages in precision machining, versatility, efficiency, and cost savings. By using these machines effectively and following best practices, manufacturers can maximize their potential and achieve optimal results in their machining processes.

Can a lathe make itself?

- A lathe is a machine used to shape wood, metal, or other materials by rotating them against a cutting tool.

- No, a lathe cannot make itself. It is created and assembled by humans using various tools and machines.

- A lathe requires skilled craftsmanship and precision engineering to manufacture.

- While a lathe can create other objects, it cannot reproduce itself.

- However, a lathe can be used to create parts or components that are used in the construction of other lathes.

Frequently Asked Questions

Below are answers to some common questions related to the topic of a lathe making itself.

Can a lathe create another lathe?

No, a lathe cannot create another lathe by itself. A lathe is a machine tool designed to shape materials, such as wood or metal, by rotating them against a fixed cutting tool. It requires external input, such as a human operator, to control its actions and perform specific tasks. While a lathe can be used to create parts and components that may be used in the construction of another lathe, the process of building an entire lathe involves multiple components and intricate mechanisms that cannot be replicated by the lathe without external intervention.

Furthermore, the initial creation of a lathe requires a complex manufacturing process involving specialized tools and skilled engineers or technicians. This process cannot be completed solely by a lathe itself, as it lacks the ability to create the necessary components and assemble them into a functioning machine.

What are the limitations of self-replication in machines?

Self-replication in machines, also known as machine self-replication or von Neumann machines, refers to the concept of a machine artificially reproducing itself. While this concept has been explored in various theoretical and scientific discussions, practical implementation faces significant limitations. One of the main limitations is the need for external resources and inputs that cannot be generated by the machine itself. Machines require raw materials, energy sources, and specialized components that cannot be created autonomously.

Additionally, the complexity involved in the construction of machines, especially intricate mechanical systems like lathes, makes self-replication a challenging task. It would require a sophisticated set of instructions, programming, and precise manufacturing capabilities. Achieving these requirements within a single machine is currently beyond our technological capabilities.

Are there any examples of self-replicating machines in nature?

Yes, there are examples of self-replicating machines in nature. One such example is biological organisms, including living cells. These cells can replicate themselves through processes such as cell division. By duplicating their genetic material and dividing, cells can create two identical copies of themselves. This replication process is the foundation of growth and reproduction in living organisms.

However, it’s important to note that natural self-replication is distinct from the concept of machine self-replication. Natural self-replication is a biological process driven by genetic information and complex biochemical mechanisms. Machine self-replication, on the other hand, involves constructing machines that have the ability to autonomously replicate or rebuild themselves, similar to the concept of a machine creating another machine.

What are the potential implications of self-replicating machines?

The concept of self-replicating machines has both exciting possibilities and potential risks. One positive implication is the potential for exponential manufacturing capabilities. If machines were able to autonomously replicate and build other machines, this could greatly enhance productivity and accelerate technological advancements. It could enable the rapid production of goods and services, leading to economic growth and improved living standards.

However, there are also concerns regarding the control and unintended consequences of self-replicating machines. Without proper safeguards, there could be a risk of unchecked proliferation, environmental impact, and ethical dilemmas. It is crucial to establish regulations and guidelines for the development and deployment of self-replicating machines to ensure they are used responsibly and for the benefit of society.

What are some current advancements in machine replication technology?

While fully self-replicating machines remain in the realm of science fiction, there have been advancements in areas such as 3D printing and automation that contribute to the field of machine replication. 3D printing allows for the creation of complex parts and components, which can be used in the assembly of various machines, including lathes. Automation technology has also improved the efficiency and precision of manufacturing processes, enabling faster and more accurate production of machine parts.

These advancements, combined with ongoing research in fields like robotics and artificial intelligence, are paving the way for future developments in machine replication technology. While we may not have self-replicating machines in the traditional sense, these advancements are bringing us closer to more autonomous and capable machines that can assist in various industries and tasks.

How I Paid Off my Lathe! Making Money Woodturning!

Summary

So, can a lathe make itself? Well, it might seem possible at first, but in reality, it’s not quite as straightforward. Although a lathe can shape metal and create intricate parts, it still requires human intervention to function and make its own components. Machines like lathes need someone to design and build them before they can even start working.

While it’s true that lathes can create replacement parts for themselves, they can’t just magically appear. Humans are the ones who create the initial lathe and all its parts. So, while a lathe is an incredible tool, it’s not capable of making a complete copy of itself. It still needs our help to come into existence in the first place.