Can a nail gun go through steel? It’s a question that may have crossed your mind if you’ve ever witnessed the power of a nail gun. Well, my young friend, you’re in for an exciting adventure of discovery! Today, we’re diving into the realm of nail guns, steel, and the incredible things they can do. So buckle up and get ready to explore the possibilities!

You might be thinking, “Wait a minute, can a tiny nail really penetrate solid steel?” It sounds like a superhero power, doesn’t it? But let me tell you, nail guns are no ordinary tools. These powerful machines pack a punch and can drive nails into various materials with impressive force and precision. Whether it’s wood, concrete, or even some types of steel, a nail gun can work wonders.

But hold on, my curious companion! There’s more to this story. Not all nail guns are created equal, and not all steel is the same. The type of nail gun and the thickness and hardness of the steel make a big difference in achieving success. So it’s time to unravel the mysteries and discover if a nail gun can indeed conquer the mighty steel. Together, we’ll unravel the secrets and unlock the power of the nail gun!

So, my young adventurer, are you ready to embark on this exploration with me? Get your thinking caps on and let’s dive headfirst into the world of nail guns and steel! It’s going to be a thrilling journey full of surprises, facts, and maybe even a little bit of “wow” along the way. Let’s find out if a nail gun can conquer steel and unleash its inner superhero powers!

Can a Nail Gun Go Through Steel?

In the world of construction, nail guns are versatile and powerful tools that help streamline various projects. However, when it comes to working with steel, many people wonder if a nail gun can penetrate this tough material. In this article, we will explore the capabilities of nail guns when it comes to steel, the limitations you may encounter, and alternative options for joining steel materials. So, let’s find out if a nail gun can truly go through steel!

The Power of Nail Guns

Nail guns are primarily designed to drive nails into softer materials such as wood or drywall. They work by utilizing compressed air, gas, or electromagnetism to forcefully propel nails into the desired surface. This efficient and time-saving method is commonly used in construction and carpentry to increase productivity and accuracy.

While nail guns are undoubtedly powerful tools, their abilities have limitations when it comes to steel. Steel is known for its hardness and strength, making it challenging for nails to penetrate without the help of more specialized tools or techniques. That being said, there are certain instances where nail guns can still be utilized with steel materials, but it’s important to understand the factors that come into play.

When attempting to use a nail gun on steel, it’s crucial to consider the thickness and hardness of the steel, as well as the type of nail being used. Thin sheets of steel may be susceptible to penetration by nails, especially if they are made of softer steel. On the other hand, thick or hardened steel will likely require more than just a nail gun to achieve successful penetration. Additionally, the type of nail being used is crucial, as regular nails may not be suitable for steel applications. Specialized nails such as hardened steel nails or concrete nails may offer better results when working with steel.

Limitations of Nail Guns on Steel

While nail guns can provide some level of penetration and join thin or soft steel materials, it’s important to be aware of their limitations. Nail guns typically do not have the force or driving power necessary to penetrate thick or hardened steel. If you attempt to use a regular nail gun on thick steel, you may find that the nails either bounce off or do not penetrate more than a surface level. This can result in weak or insecure joints, which is not ideal when working with structural steel or other load-bearing applications.

Another limitation of nail guns on steel is the risk of damaging the gun itself. Steel is a hard material and can cause excessive wear or damage to the nail gun, particularly if it is not designed or equipped to handle steel applications. The force required to drive a nail into steel can place significant stress on the internal components of the nail gun, potentially leading to malfunctions or reduced lifespan.

Overall, while it is possible to use a nail gun on steel in certain situations, it is not the most reliable or recommended method for joining steel materials. For stronger and more secure connections, it is advisable to explore alternative options specifically designed for steel applications.

Alternative Options for Joining Steel

When it comes to joining steel materials, there are several alternative options that offer stronger and more reliable connections compared to nail guns. Some of the commonly used methods include:

- Welding: Welding is a popular method for joining steel as it creates a strong and permanent bond. With the use of heat and filler materials, two pieces of steel can be fused together to form a secure connection.

- Bolting: Bolting involves the use of bolts, nuts, and washers to join steel materials. This method allows for easy disassembly and reassembly, making it suitable for applications requiring flexibility or future modifications.

- Riveting: Riveting involves driving a metal pin or rivet through two pieces of steel and then deforming the end of the rivet to secure it in place. This method creates a strong and permanent connection.

- Adhesive bonding: Adhesive bonding utilizes high-strength adhesives specifically designed for metal-to-metal applications. This method is suitable for lightweight or non-structural steel connections.

Each of these alternative options has its advantages and considerations, depending on the specific project requirements. When working with steel, it is important to assess the application, load-bearing capacity, and durability needed to determine the most appropriate method for joining the materials.

Conclusion:

While nail guns are powerful tools that can drive nails into various materials, they have limitations when it comes to steel. While thin or soft steel may be penetrable with a nail gun, thick or hardened steel typically requires more specialized tools or techniques for successful penetration. It is essential to consider the factors such as steel thickness, hardness, and the type of nail being used when attempting to work with steel using a nail gun.

For stronger and more secure connections with steel materials, alternative options such as welding, bolting, riveting, or adhesive bonding are recommended. These methods provide stronger joints and are specifically designed for steel applications. It is crucial to select the appropriate method based on the project requirements, load-bearing capacity, and durability. By choosing the right method and tools, you can ensure reliable and robust connections in your steel construction projects.

Can a Nail Gun Go Through Steel?

When it comes to using a nail gun to penetrate steel, it’s important to understand that not all nail guns are designed for this purpose. Some nail guns are specifically made for woodworking and may not have the power needed to penetrate steel.

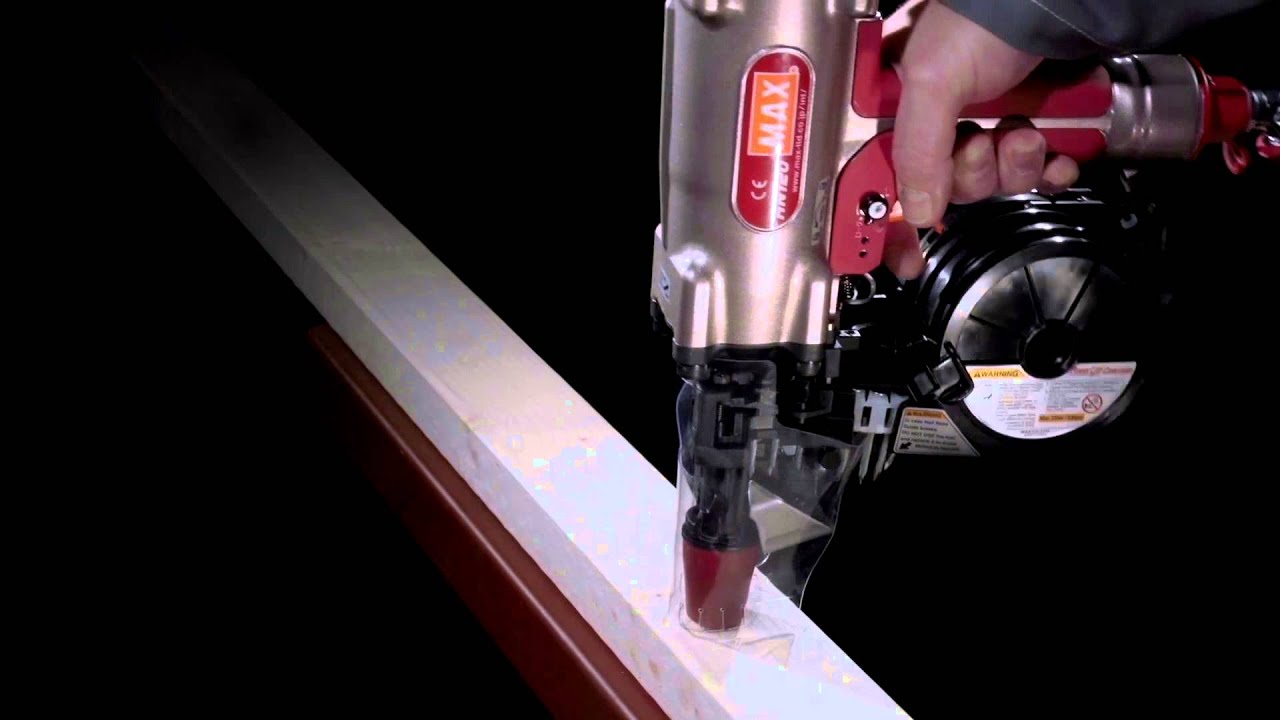

- If you want to drive nails into steel, you’ll need a specialized nail gun called a framing nailer or a metal connector nailer.

- These nail guns are designed with more power and typically use larger and stronger nails that can penetrate steel.

- Using a regular nail gun on steel can lead to the nail bending or not penetrating the surface at all.

- It’s important to always use the right tools for the job to ensure safety and efficiency.

- Before attempting to use a nail gun on steel, make sure to read the manufacturer’s instructions and guidelines to ensure compatibility.

Frequently Asked Questions

Are you wondering if a nail gun can go through steel? Find the answers to your questions below!

1. Can a nail gun be used to penetrate steel surfaces?

Unfortunately, a regular nail gun is not designed to go through steel. Most nail guns are designed for softer materials like wood or drywall. They simply do not have the power or the right type of nails to effectively penetrate steel surfaces. If you attempt to use a regular nail gun on steel, you will likely end up damaging the tool and causing frustration.

If you need to fasten materials to steel surfaces, you will need a specialized tool like a powered impact driver or a stud welder. These tools are specifically designed to handle steel and can easily penetrate its surface. So, remember, while a nail gun is versatile for many applications, using it on steel surfaces is not one of them.

2. What type of tool can effectively penetrate steel using nails?

When it comes to penetrating steel surfaces, a nail gun won’t cut it, but there are other tools that can get the job done. One of them is a powered impact driver. These tools are designed with high torque and can drive nails or screws into steel with ease. They provide the force needed to break through the tough surface of steel and securely fasten materials.

Another option is a stud welder. This tool uses an electric current to weld the nail or stud to the steel surface. It creates a strong bond that holds materials firmly in place. So, if you need to work with steel and want to use nails, consider these specialized tools instead of a regular nail gun.

3. Can a nail gun be dangerous when used incorrectly on steel?

Yes, using a regular nail gun incorrectly on steel surfaces can be dangerous. The nails are not designed to penetrate steel, so the tool may recoil, potentially causing injury. Furthermore, the nails may ricochet, posing a safety risk to the operator or others in the vicinity.

Always follow the manufacturer’s instructions and safety guidelines when using any tool. If you need to work with steel, make sure to use the appropriate tools for the job to ensure your safety and the success of your project.

4. What are the advantages of using a powered impact driver on steel?

Powered impact drivers offer several advantages when it comes to working with steel. First, they provide the necessary torque to penetrate the tough surface of steel, making it easier to drive nails or screws. They offer more power than a regular nail gun, ensuring reliable fastening on steel surfaces.

Second, powered impact drivers often have adjustable settings, allowing you to control the speed and torque for different applications. This versatility makes them suitable for various projects and materials, including steel. Additionally, they typically offer a compact and ergonomic design, making them easy to handle and maneuver in tight spaces.

5. Can a nail gun go through thin sheets of steel?

While a regular nail gun is not meant for steel, it may be able to penetrate thin sheets of steel to some extent. However, it’s important to note that this is not its primary purpose, and the results may not be reliable or secure. The nails used in a regular nail gun are designed for wood or other softer materials, so they may not provide an adequate hold in thin sheets of steel.

If you need to fasten materials to thin sheets of steel, it’s recommended to use specialized fasteners like self-tapping screws or rivets. These are specifically designed to secure materials to metal surfaces and provide a stronger and more reliable hold than nails from a regular nail gun.

The Ultimate Guide to Using a Manual Steel Nail Gun

Summary

So, can a nail gun go through steel? Well, the answer is no. Nail guns are designed for wood, and they don’t have enough power to penetrate steel. Steel is much stronger and thicker than wood, so it requires specialized tools like drills or impact drivers to make a hole. If you ever need to work with steel, make sure you have the right tools for the job!

Remember, safety is always important when working with tools. Nail guns can be dangerous if not used properly, so it’s essential to follow the manufacturer’s instructions and wear protective gear. Always prioritize your safety and consult a professional if you have any doubts. Happy building!