Can a table saw be used to cut metal? It’s a question many DIY enthusiasts and woodworkers have pondered. Well, let’s dive into this fascinating topic and find out if a trusty table saw can handle the challenge of slicing through metal.

Now, picture this: you’re working on a project that involves both wood and metal components. It’s all coming together, and you’re ready to make clean and precise cuts. You turn to your loyal table saw, wondering if it can cut through the metal material just as effortlessly as it slices through wood.

So, let’s explore the possibilities, shall we? Can a table saw be used to cut metal? Let’s find out together!

How to Cut Metal Using a Table Saw:

- Ensure you have a carbide-toothed blade specifically designed for cutting metal.

- Secure the metal piece firmly in place and adjust the fence for accuracy.

- Wear appropriate safety gear, including goggles and gloves.

- Turn on the table saw and slowly feed the metal into the blade, maintaining a steady pace.

- Keep your hands clear and let the saw do the work, avoiding any sudden movements.

Remember to prioritize safety and research the specific blade and techniques for cutting metal with a table saw.

Can a Table Saw be Used to Cut Metal?

Table saws are commonly used for cutting various materials, such as wood and plastic. However, many people wonder if they can also be used to cut metal. In this article, we will explore whether a table saw is suitable for cutting metal and discuss the considerations, limitations, and safety measures involved in using a table saw for metalworking.

Understanding the Limitations of Table Saws for Metal Cutting

Although table saws are powerful tools, they are primarily designed for woodworking applications. The blades used in table saws are typically designed for cutting wood and may not be suitable for cutting metal. Metal cutting requires a different type of blade, as the hardness and thickness of metal can pose challenges not encountered when cutting wood.

Additionally, the speed of a table saw might not be ideal for cutting metal. Metal cutting requires a slower cutting speed to avoid overheating the blade and prevent damage to the material. Table saws typically operate at higher speeds designed for smoother cuts in wood.

Can You Use a Table Saw to Cut Thin Sheet Metal?

While a table saw may not be suitable for cutting thicker metals, it can be used to cut thin sheet metal under certain conditions. If you need to make straight, precise cuts in thin sheet metal, a table saw can be a viable option. However, it is important to take several factors into consideration to ensure safety and optimal results.

First, you need to use the correct blade designed specifically for cutting metal. A carbide-tipped blade with a high tooth count is recommended for cutting thin sheet metal on a table saw. This type of blade will provide cleaner cuts while reducing the risk of overheating or damaging the material.

Furthermore, it is crucial to take the necessary safety precautions. Always wear appropriate personal protective equipment (PPE), such as safety goggles and gloves, when working with metal on a table saw. Additionally, be mindful of the metal’s dimensions, securing it properly to prevent movement during the cutting process.

The Importance of Proper Blade Selection

When using a table saw for cutting metal, selecting the right blade is crucial for achieving clean and accurate cuts. For cutting thicker metals, such as steel or aluminum, specialized metal-cutting blades with a lower tooth count and more aggressive tooth geometry are recommended.

These blades are designed to withstand the rigors of cutting dense and harder metals, ensuring efficient and safe operation. It is important to note that using the wrong blade for metal cutting can lead to dulling, overheating, or even blade breakage, posing serious safety hazards.

Before attempting to cut metal on a table saw, always consult the manufacturer’s guidelines and recommendations for blade selection. Using the appropriate blade for the specific type and thickness of metal will improve cutting efficiency and reduce the risk of accidents.

Maximizing Safety when Using a Table Saw for Metal Cutting

Working with a table saw can be inherently dangerous, and when cutting metal, additional safety precautions are necessary. Here are some essential safety measures to observe:

- Always wear appropriate PPE, including safety goggles, gloves, and hearing protection.

- Inspect the blade for any signs of damage or dullness before each use.

- Use a blade guard and anti-kickback device to prevent accidents and kickbacks.

- Ensure the table saw is securely placed on a stable surface and the materials are properly secured.

- Keep hands and fingers at a safe distance from the blade by using push sticks or other appropriate tools.

By following these safety practices, you can minimize the risk of injuries and accidents while using a table saw to cut metal.

Alternatives to Table Saws for Metal Cutting

If you require more precise or heavy-duty metal cutting, it is advisable to explore alternative tools specifically designed for metalworking. Some popular options include:

- Metal chop saws: These specialized saws are designed specifically for cutting metal and offer better control and cutting efficiency.

- Band saws: Band saws equipped with a metal-cutting blade can handle a wide range of metal cutting tasks and offer more versatility.

- Plasma cutters: Plasma cutters use high-temperature plasma to melt through metal, making them ideal for thicker and tougher metals.

Using the right tool for the job ensures better results, improved safety, and increased efficiency when it comes to cutting metal.

Key Considerations for Using a Table Saw to Cut Metal

Before attempting to cut metal on a table saw, it is important to keep the following considerations in mind:

- Table saws are primarily designed for woodworking applications and may not be the most efficient or suitable option for cutting metal.

- Using the correct blade designed specifically for metal cutting is crucial to ensure clean cuts and prevent accidents.

- Thicker metals may require specialized metal-cutting tools such as chop saws, band saws, or plasma cutters for optimal results.

- Always prioritize safety by wearing the appropriate PPE and following safety guidelines and precautions.

- Consider the scope and requirements of your metal cutting project to determine the most suitable tool for the job.

Conclusion

While it is possible to use a table saw for cutting metal, it is important to understand the limitations and take the necessary precautions. Table saws can be used to cut thin sheet metal, but the correct blade, appropriate safety measures, and thorough understanding of the tool’s capabilities are imperative for safe and efficient metal cutting. For more precise or heavy-duty metal cutting, it is advisable to explore specialized tools designed specifically for metalworking. By choosing the right tool for the job and prioritizing safety, you can achieve optimal results in all your metal cutting projects.

Can a Table Saw Be Used to Cut Metal?

Yes, a table saw can be used to cut metal, but it’s not recommended for several reasons:

- Table saw blades are designed for cutting wood, not metal.

- Metal can create sparks when cut, posing a safety risk.

- Table saws lack the necessary power and speed to cut through metal efficiently.

- Using a table saw to cut metal can damage the saw and result in inaccurate cuts.

- There are specific tools, like metal cutting bandsaws or angle grinders, designed for cutting metal that are safer and more effective.

Frequently Asked Questions

Do you have questions about using a table saw to cut metal? We have the answers you’re looking for!

1. Can a table saw be used to cut metal?

While a table saw is primarily designed for cutting wood, it is possible to use it to cut metal with the right precautions and equipment. However, it’s important to note that using a table saw for metal cutting poses some risks. Metal can produce sparks, heat, and debris that can damage the saw or cause injury. It’s important to take safety measures and equip your table saw accordingly if you choose to cut metal with it.

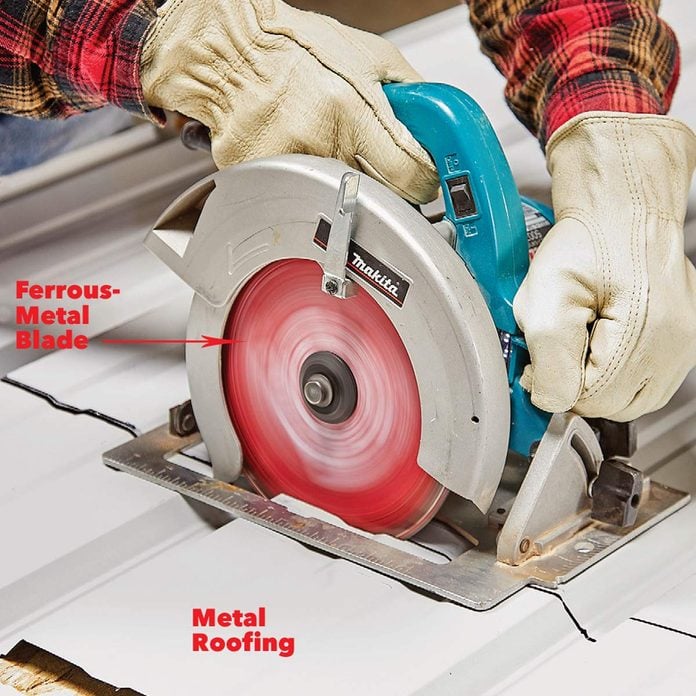

Prior to cutting metal, make sure your saw is equipped with a blade specifically designed for metal cutting. These blades are usually made from carbide or other high-speed steel materials and have a finer tooth configuration. Additionally, ensure that your table saw has a metal cutting insert or a proper metal cutting fence to prevent damage to the machine and provide stability during cutting. Lastly, always wear appropriate personal protective equipment, such as safety goggles, gloves, and a dust mask, to protect yourself from sparks, metal chips, and dust.

2. What types of metal can be cut with a table saw?

A table saw can be used to cut various types of metal, including steel, aluminum, brass, and copper. However, it’s important to consider the thickness and hardness of the metal before attempting to cut it. Table saws are better suited for cutting thinner metal sheets or small metal pieces rather than thick or heavy-duty metal.

If you’re planning to cut thick or heavy metals, it’s often recommended to use specialized metal-cutting tools, such as an angle grinder or a metal-cutting band saw. These tools are designed to handle the higher forces and heat generated by cutting thicker metals, providing more precise and efficient results.

3. What precautions should I take when using a table saw to cut metal?

When using a table saw to cut metal, it’s important to follow certain safety precautions to minimize the risks involved. Firstly, ensure that your work area is clean and free of any flammable materials to prevent sparks from igniting a fire. Additionally, secure the metal piece firmly with clamps or a metal-cutting vise to ensure it doesn’t move during cutting.

Always make sure to wear appropriate personal protective equipment, including safety goggles to protect your eyes from sparks and debris, gloves to avoid cuts, and a dust mask to prevent inhaling metal dust particles. It’s also important to use a slow feed rate to prevent overheating and prolong the life of the blade. Finally, be cautious of the metal chips and sharp edges that may be produced during cutting, as they can cause injuries. Use a brush or a vacuum to clean the work area after finishing the cut.

4. How do I choose the right blade for cutting metal on a table saw?

Choosing the right blade for cutting metal on a table saw is essential for achieving clean, precise cuts and ensuring safety. Look for blades specifically designed for metal cutting, such as those made from carbide or high-speed steel. These blades are engineered to withstand the heat and hardness of metal, with a tooth configuration optimized for efficient cutting.

The number of teeth on the blade is an important consideration. Blades with fewer teeth, such as 24 teeth, are suitable for fast and rough cuts, while blades with more teeth, such as 60 or 80 teeth, provide smoother and more precise cuts. Consider the thickness and hardness of the metal you’ll be cutting to determine the appropriate tooth count. It’s also essential to have a blade that’s compatible with your table saw’s arbor size and RPM rating for safe and efficient operation.

5. Are there any alternative tools for cutting metal besides a table saw?

Absolutely! While a table saw can be used for cutting metal, there are several alternative tools available that are specifically designed for metal cutting. One popular option is an angle grinder, which is handheld and equipped with a cutting wheel or abrasive disc that can slice through various metals with precision.

Another effective tool for cutting metal is a metal-cutting band saw. This specialized saw uses a continuous band of toothed metal that rotates around two wheels, allowing for straight and curved cuts in metal. For thicker and heavy-duty metal cutting, plasma cutters and oxy-acetylene torches are often used, as they can produce extremely high heat to melt through the metal.

Summary

You might be wondering if you can use a table saw to cut metal. The answer is no. Metal can damage the saw’s blade and kick back, causing accidents. It’s best to use a hacksaw or a metal-cutting circular saw for cutting metal instead.

Using a table saw for metal can be dangerous, while using the right tools can ensure a safe and effective metal-cutting process. Remember to prioritize your safety and seek the appropriate tools to get the job done.