Picture this: you’ve got a trusty wood lathe sitting in your workshop, but you can’t help but wonder, can it be used for metal? Well, my young DIY enthusiast, you’ve come to the right place! In this article, we’ll explore the intriguing question: “Can a wood lathe be used for metal?”

Now, you might be thinking, “Wait a minute, a wood lathe turning metal? Is that even possible?” Well, hold on tight because we’re about to dive into the exciting world of lathe versatility. We’ll uncover whether your wood lathe has the potential to tackle some metal-machining tasks.

Grab your goggles, roll up your sleeves, and let’s embark on this enlightening journey together to discover the wonders of a wood lathe and its potential to handle the tough stuff – metal! So, are you ready to unleash your inner craftsman and learn something new? Let’s dive right in!

Can a Wood Lathe be Used for Metal?

Wood lathes are a staple in woodworking shops, but can they be used for working with metal as well? Many DIY enthusiasts and hobbyists wonder if they can repurpose their trusty wood lathe to handle metals. In this article, we will dive deep into the topic of whether a wood lathe can be used for metal, exploring the limitations, challenges, and potential workarounds. So, if you’ve ever wondered about expanding the capabilities of your wood lathe, read on to find out if it’s possible to use it for metalworking.

The Challenges of Using a Wood Lathe for Metal

Wood lathes are specifically designed for working with softer materials like wood. They are not built to withstand the rigors of metalworking. The key challenge lies in the speed and power required to effectively shape and cut through metal. Wood lathes typically run at lower speeds and have less torque compared to dedicated metal lathes. This can make it incredibly difficult, if not impossible, to achieve the necessary precision and efficiency for metalworking tasks.

Furthermore, the cutting tools used on wood lathes are designed for wood, with their geometry optimized for cutting across the grain. These tools may not be suitable for working with metals, which require specific cutting angles and tool geometries. As a result, using wood lathe tools on metal can result in poor cutting performance, tool damage, and potential safety hazards.

The Limitations of Wood Lathes for Metalworking

While it may be tempting to utilize the existing tools and capabilities of a wood lathe for metalworking, it’s important to understand the limitations. Here are some key factors to consider:

- Speed: Wood lathes typically operate at slower speeds compared to metal lathes, which are designed to handle the higher cutting speeds required for metalwork. Working at slower speeds can lead to poor cutting performance and inefficient shaping of metal.

- Torque: Metalworking often demands higher torque to cut through tougher materials. Wood lathes may not have enough torque to effectively work with metals, resulting in tool chatter, rough finishes, and potential damage to the lathe itself.

- Tool Geometry: Wood lathe tools are optimized for cutting across the grain of wood. They may not possess the correct tool geometry and cutting angles needed for metalworking, resulting in reduced cutting efficiency and potentially unsafe conditions.

- Machine Stability: Wood lathes are typically designed for the inherent stability of woodturning. The vibrations and forces generated while working with metals can put additional stress on the lathe, potentially causing damage or compromising stability.

Workarounds and Considerations for Using a Wood Lathe for Metal

While a wood lathe may not be the most ideal tool for metalworking, there are some workarounds and considerations for those who wish to experiment with metal on a wood lathe:

- Use a Metal Spindle Adapter: A metal spindle adapter can allow you to attach metalworking tools to your wood lathe. However, it’s important to note that this may not overcome the limitations of speed, torque, and tool geometry.

- Stick to Softer Metals: If you insist on using your wood lathe for metal, it’s best to stick to softer metals like aluminum or brass. These metals are easier to work with and put less strain on the lathe.

- Upgrade to a Metal Lathe: If you find yourself pursuing metalworking on a regular basis, it might be worth investing in a dedicated metal lathe. These lathes are specifically designed for the challenges and demands of metalworking, providing better speed, torque, and tool support.

Can a wood lathe be used for metal?

- While a wood lathe is primarily designed for working with wood, it is possible to use it for metal projects.

- However, using a wood lathe for metal requires a few modifications and additional tools.

- One of the main considerations is the speed at which the lathe operates, as metal requires slower speeds than wood.

- Special metal-cutting tools and accessories are needed to ensure safe and efficient metal turning on a wood lathe.

- It is important to note that using a wood lathe for metal may not provide the same precision and accuracy as a lathe specifically designed for metalworking.

Frequently Asked Questions

Are you curious about whether you can use a wood lathe for metalwork? We’ve got the answers you’re looking for. Check out these frequently asked questions for all the information you need:

1. Can a wood lathe be used for metal? What are the limitations?

Yes, a wood lathe can be used for metalwork, but there are some limitations to keep in mind. Wood lathes are designed specifically for working with wood, so they may not have the speed or power necessary for metalwork. Additionally, the tool rests and accessories on a wood lathe may not be suitable for metal spinning or shaping.

However, with some modifications and the right attachments, it is possible to use a wood lathe for light metalwork. Make sure to use caution and follow proper safety procedures when attempting this. Keep in mind that if you plan to work extensively with metal, investing in a dedicated metal lathe would be the best option.

2. What modifications are needed to use a wood lathe for metalwork?

If you want to use a wood lathe for metalwork, there are a few modifications you’ll need to make. First, you’ll need to upgrade the motor to ensure it has enough power to handle the demands of metalworking. You may also need to adjust the speed settings to accommodate the higher RPMs required for metal. Additionally, you’ll need to replace the tool rests and accessories with ones designed for metal spinning or shaping.

It’s important to note that these modifications can vary depending on the specific wood lathe you have and the type of metalwork you plan to do. Consult the lathe’s user manual or reach out to the manufacturer for guidance on the necessary modifications, or consider seeking advice from experienced woodworkers or metalworkers.

3. What safety precautions should be taken when using a wood lathe for metal?

Safety should always be a top priority when working with tools, especially when using a wood lathe for metalwork. Here are some essential safety precautions to take:

– Wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, to protect yourself from metal shavings and debris.

– Securely fasten the metalwork piece to the lathe to prevent it from spinning or becoming loose during operation.

– Use sharp and properly maintained tools to minimize the risk of accidents or injuries.

– Work slowly and steadily, especially when starting out, to maintain control and reduce the likelihood of mistakes or mishaps.

– Familiarize yourself with the lathe’s emergency stop button and make sure it is easily accessible.

4. Can I use the same cutting tools for wood and metal on a wood lathe?

The cutting tools used for woodturning are not typically suitable for metalwork on a wood lathe. Woodturning tools are designed specifically for cutting wood fibers, while metalworking tools need to be much sharper and have a different cutting angle to effectively work with metal. Therefore, it’s recommended to invest in separate cutting tools specifically designed for metalworking if you plan to use a wood lathe for metal.

Using woodturning tools on metal can result in dulling the tools quickly, causing poor performance, and potentially damaging the piece you are working on. Always use the appropriate tools for the material you are working with to ensure the best results and maintain the longevity of your tools.

5. What are the advantages and disadvantages of using a wood lathe for metalwork?

Using a wood lathe for metalwork can have both advantages and disadvantages. Some advantages include the cost savings compared to purchasing a dedicated metal lathe, the versatility of being able to switch between wood and metal projects, and the familiarity of working on a lathe you may already own.

However, there are also disadvantages to consider. Wood lathes are generally not as powerful as metal lathes, so their capabilities for metalwork may be limited. The modifications required to use a wood lathe for metal can be time-consuming and may require additional investment. Additionally, the safety considerations and the need for separate tools for metalwork add complexity to the process.

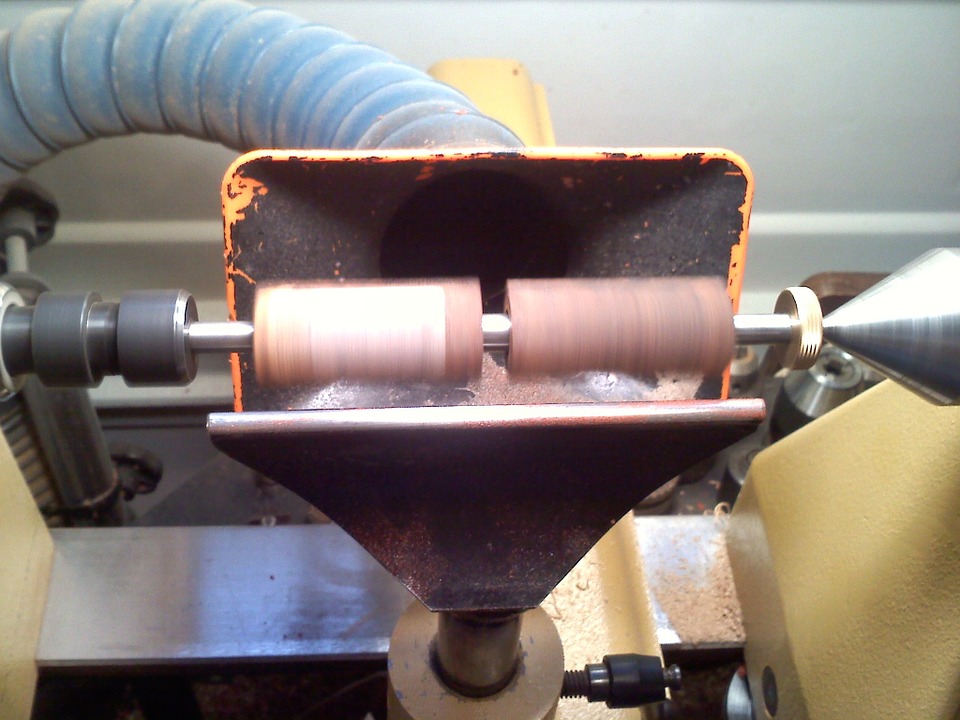

Turning Metal on a Wood Lathe – A ‘Woodturning’ Experiment

Summary

A wood lathe is not designed for working with metal because the materials and techniques are different. Metal requires higher speeds and more power than a wood lathe can provide.

However, there are some modifications that can be made to a wood lathe, such as adding a metal-cutting tool and adjusting the speed settings, to work with soft metals like aluminum. But it’s important to note that using a wood lathe for metal comes with risks and challenges, so it’s better to invest in a proper metal lathe for accurate and safe metalworking.