Can a circular saw cut rubber? If you’ve ever wondered about this, you’re in the right place! Rubber is a soft and flexible material that can be tricky to cut with traditional tools. But what about a circular saw? Let’s dive in and find out!

Rubber is commonly used in various applications, from gaskets and seals to tires and flooring. But if you need to make precise cuts or shape rubber for a specific project, you might be wondering if a circular saw can get the job done.

In this article, we’ll explore whether a circular saw is suitable for cutting rubber and discuss some essential tips to ensure a clean and effective cut. So grab your safety goggles, and let’s get cutting!

Can Circular Saw Cut Rubber? Exploring the Possibilities

When it comes to cutting materials, circular saws are versatile tools that are commonly used in woodworking and construction projects. But what about rubber? Can a circular saw effectively cut through this flexible material? In this article, we will dive into the world of circular saws and explore whether they are suitable for cutting rubber. We’ll discuss the challenges of cutting rubber, the types of blades that work best, safety considerations, and alternative methods for cutting rubber. So, if you’re curious about whether a circular saw can handle the task, keep reading to find out!

The Challenges of Cutting Rubber

Before we delve into whether a circular saw can cut rubber, it’s important to understand the unique challenges of working with this material. Rubber is a flexible and elastic material that can pose difficulties when it comes to cutting. Its soft and pliable nature can cause it to snag, warp, or tear if not cut carefully. This makes it essential to choose the right blade and follow proper techniques to achieve clean and accurate cuts. Additionally, rubber tends to produce a lot of smoke and can generate heat during the cutting process, which may affect the saw’s performance.

The Right Blade for the Job

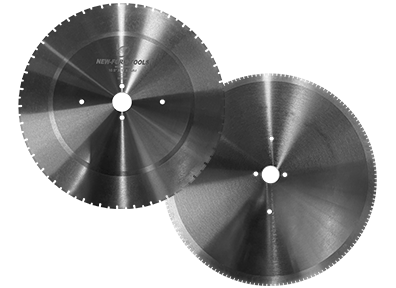

If you’re considering using a circular saw to cut rubber, selecting the right blade is crucial for achieving clean and precise cuts. A blade specifically designed for cutting rubber, such as a carbide-tipped blade, is highly recommended. These blades are equipped with sharp, durable teeth that can effectively slice through the material without tearing or snagging. Additionally, using a blade with fine teeth will help reduce the amount of smoke and heat generated during cutting. It’s important to note that using a general-purpose blade or one designed for other materials may not yield the desired results, and can potentially ruin the rubber.

Safety Considerations

When working with a circular saw, proper safety precautions are essential to prevent accidents and injuries. When cutting rubber, it’s recommended to wear safety goggles to protect your eyes from any debris or particles that may be released during the cutting process. Using gloves will provide a better grip and protect your hands from potential hazards. Additionally, ensure that the work area is well-ventilated to minimize the buildup of smoke. Lastly, always follow the manufacturer’s instructions and guidelines for the specific circular saw you are using, as different models may have unique safety considerations.

Alternatives to Circular Saw Cutting

While a circular saw can be used to cut rubber, there are alternative methods that may be more suitable depending on the specific project. If you are working with thinner sheets of rubber, using a utility knife or a pair of heavy-duty scissors may be more convenient and yield better results. For thicker pieces or more intricate cuts, a laser cutter or water jet cutter can provide precise and clean results. These methods may require specialized equipment and expertise, but they offer greater control and minimize the risk of damaging the rubber material.

Benefits of Using a Circular Saw for Cutting Rubber

If you decide to use a circular saw for cutting rubber, there are several benefits to consider. Firstly, circular saws are widely available and relatively affordable compared to other specialized cutting tools. They are also highly versatile and can be used for various other cutting tasks, making them a valuable addition to any workshop. Additionally, with the right blade and proper technique, circular saws can provide fast and efficient cutting results. Lastly, using a circular saw allows for greater control and precision compared to alternative methods like utility knives or heavy-duty scissors.

Vs. Other Cutting Methods for Rubber

While circular saws can be a suitable option for cutting rubber, it’s important to compare them with other cutting methods to determine the best approach for your specific project. Here are a few alternatives to consider:

1. Utility Knife/Pairs of Scissors

For thinner sheets of rubber or simple cuts, using a utility knife or a pair of heavy-duty scissors may be a more convenient and cost-effective option. However, it’s important to note that maintaining steady and precise cuts can be challenging with these tools, especially for thicker pieces or intricate shapes.

2. Laser Cutter

A laser cutter is a highly precise and efficient method for cutting rubber. It uses a focused beam of light to vaporize the material, resulting in smooth and clean cuts without any physical contact. However, laser cutters can be expensive and may require specialized training.

3. Water Jet Cutter

If you’re looking for exceptional precision and a clean finish, a water jet cutter is an excellent choice for cutting rubber. This method uses a high-pressure stream of water mixed with an abrasive substance to cut through the material. While water jet cutters offer unparalleled accuracy, they can be costly and require specialized equipment.

Tips for Cutting Rubber with a Circular Saw

If you’ve decided to use a circular saw for cutting rubber, here are some helpful tips to ensure the best results:

1. Secure the Material

Before cutting, make sure the rubber material is firmly secured to prevent any movement or shifting during the cutting process. This can be done by using clamps or adhesive tape to secure the edges or by placing the rubber on a stable surface.

2. Measure and Mark

Take accurate measurements and use a straightedge or a ruler to mark the precise cutting line on the rubber. This will help guide your cuts and ensure the desired shape or size.

3. Cut at the Right Speed

When using a circular saw, it’s important to maintain a steady and consistent cutting speed to avoid blade slippage or burning the rubber. Start cutting at a slow speed and gradually increase as you feel comfortable and confident.

4. Use a Guide

For straight cuts, consider using a guide or a fence to ensure a straight and even cutting line. This can be as simple as a straight piece of wood clamped to the rubber to act as a guide for the saw.

5. Clean the Blade

After cutting a few passes, the blade may accumulate rubber residue or debris, which can affect its performance. Make sure to clean the blade periodically to maintain optimal cutting results.

Conclusion

So, can a circular saw cut rubber? The answer is yes! With the right blade, proper technique, and safety precautions, a circular saw can effectively slice through rubber materials, providing clean and accurate cuts. However, it’s important to consider the challenges and alternatives depending on the specific project requirements. Whether you choose a circular saw or an alternative method, always prioritize safety and follow the appropriate guidelines to achieve the best results. Happy cutting!

Key Takeaways: Can Circular Saw Cut Rubber?

- Yes, a circular saw can cut rubber.

- When cutting rubber with a circular saw, use a fine-toothed blade specifically designed for cutting rubber or plastics.

- Make sure to secure the rubber material tightly before cutting to avoid movement and ensure a clean cut.

- Wear appropriate safety gear, such as safety goggles and gloves, when cutting rubber with a circular saw.

- Take your time and apply steady pressure to the saw, allowing it to cut through the rubber smoothly and efficiently.

Frequently Asked Questions

In this section, we will answer some common questions related to cutting rubber with a circular saw.

1. Can a circular saw be used to cut through rubber?

Yes, a circular saw can be used to cut through rubber. However, it is important to use a proper blade specifically designed for cutting rubber. A regular wood-cutting blade will not be effective and may even damage the material. Look for a blade with fine teeth and a high tooth count, as this will provide a cleaner cut.

When cutting rubber with a circular saw, it is also important to choose the right blade speed and adjust the depth of cut. Take your time and use steady, controlled movements to ensure a precise cut. Always wear appropriate safety gear, such as safety glasses and gloves, to protect yourself during the cutting process.

2. What type of blade should I use to cut rubber with a circular saw?

To cut rubber with a circular saw, you should use a blade specifically designed for cutting rubber materials. These blades typically have fine teeth and a high tooth count, which helps to create a clean and smooth cut. Avoid using standard wood-cutting blades, as they may not be effective and can cause damage to the material.

When choosing a blade, consider the thickness and density of the rubber you are cutting. Thicker and denser rubber may require a more robust and durable blade. It is also important to ensure that the blade is compatible with your specific circular saw model. Always refer to the manufacturer’s recommendations and guidelines for blade selection.

3. What are the safety precautions when cutting rubber with a circular saw?

When cutting rubber with a circular saw, it is essential to take certain safety precautions to protect yourself and ensure a safe working environment. First and foremost, always wear appropriate safety gear, including safety glasses and gloves, to protect against any potential debris or injuries.

Make sure to secure the rubber material properly before starting the cutting process. An unsecured piece of rubber can move or vibrate during cutting, which can be hazardous. Use clamps or other suitable methods to hold the rubber securely in place.

4. Can a circular saw create precise cuts in rubber?

With the use of the right blade and proper technique, a circular saw can create precise cuts in rubber. It is important to choose a blade specifically designed for cutting rubber materials, as this will ensure a cleaner and smoother cut. Additionally, taking your time and using steady, controlled movements will help to achieve more precise cuts.

For intricate cuts or curves, it may be beneficial to use a jigsaw or another specialized cutting tool. These tools offer greater maneuverability and control, making it easier to achieve precise cuts in rubber. However, for straight cuts or larger pieces of rubber, a circular saw can still be an effective and precise cutting tool.

5. Are there any alternative tools for cutting rubber besides a circular saw?

Yes, there are alternative tools available for cutting rubber besides a circular saw. One popular option is a utility knife or a box cutter. These tools offer precision and control, making them suitable for smaller and more intricate cuts. However, they may not be as efficient for larger or thicker pieces of rubber.

Another alternative is a jigsaw, which is designed for making curved and intricate cuts. A jigsaw allows for greater maneuverability and control, which can be beneficial when working with rubber. However, a jigsaw may not be as effective for straight cuts or thicker rubber materials.

Tool Hack: Cutting Rubber

Summary

So, can a circular saw cut rubber? The answer is yes! With the right blade and technique, you can use a circular saw to cut rubber materials. Just make sure to choose a blade with fine teeth and use a slower speed. Safety precautions should always be followed, like wearing goggles and gloves.

In conclusion, while it may be a bit trickier than cutting wood or metal, cutting rubber with a circular saw is definitely possible. Remember to use the right blade, go slow, and stay safe!