So, you’re wondering if you can cut perspex with a hand saw, huh? Well, let me tell you, it’s a question that many DIY enthusiasts have asked at some point. You see, sometimes you just don’t have access to power tools or maybe you prefer the good ol’ manual approach. Either way, it’s worth exploring if a hand saw can do the job. So, let’s dive in and find out!

When it comes to cutting perspex, it’s important to consider the properties of this material. Perspex, also known as acrylic, is a type of plastic that can be easily molded and shaped. It’s widely used in various applications like signage, window panels, and even furniture. Now, while it’s not as tough as metal or wood, perspex can still present some challenges when it comes to cutting.

Now, let’s get to the burning question: Can you cut perspex with a hand saw? The answer is yes, you can! However, there are a few important things to keep in mind before you grab that saw and start cutting away. It’s crucial to choose the right type of hand saw, be patient and take your time, and use proper safety precautions to ensure a clean and precise cut. So, let’s explore these points in more detail and get you well-equipped for your perspex-cutting adventure!

Yes, you can cut Perspex with a hand saw! While it’s not the most efficient method, it can be done with the right precautions.

To cut Perspex with a hand saw:

- Start by marking the cut line on the Perspex sheet.

- Secure the Perspex sheet to prevent it from moving.

- Use a fine-toothed hand saw and make a slow, steady cut along the marked line.

- Apply minimal pressure to avoid chipping or cracking the Perspex.

- Sand the edges to smoothen them after cutting.

Remember to wear appropriate safety gear and take your time to ensure a clean cut!

Can I Cut Perspex with a Hand Saw?

Introduction:

When it comes to cutting materials, it’s important to have the right tools for the job. But what if you don’t have access to power tools, like a circular saw or a jigsaw? Can you still cut materials like Perspex with a simple hand saw? In this article, we’ll explore whether cutting Perspex with a hand saw is possible, what tools you’ll need, and some tips for achieving clean and accurate cuts. So, if you’re curious about how to tackle your Perspex cutting project with just a hand saw, read on!

The Basics of Cutting Perspex

Introduction:

Before we dive into the details of cutting Perspex with a hand saw, let’s start with the basics. Perspex is a brand name for acrylic plastic, known for its clarity, strength, and versatility. It’s commonly used as a substitute for glass due to its lighter weight and impact-resistance. When it comes to cutting Perspex, there are a few important things to keep in mind.

Choosing the Right Hand Saw

When it comes to cutting Perspex with a hand saw, it’s important to choose the right tool for the job. While any hand saw can technically cut through Perspex, a fine-toothed saw, such as a coping saw or a hacksaw with a metal-cutting blade, is recommended. These saws have smaller teeth that can make more precise cuts and reduce the risk of chipping or cracking the Perspex.

If you already have a hand saw with larger teeth, you can still use it, but it’s essential to go slow and use caution to avoid damaging the material. Additionally, using a hand saw with a miter box or a clamping guide can help ensure straight and accurate cuts.

Remember to always wear safety goggles and gloves when working with any type of hand saw, as well as a mask to protect against any dust particles that may be released during the cutting process.

Preparing the Perspex for Cutting

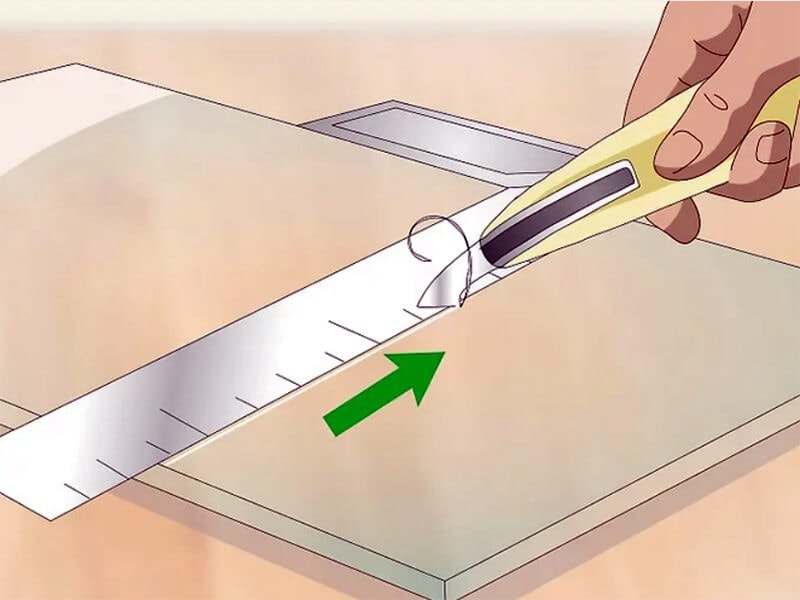

Before you start cutting, it’s important to properly prepare the Perspex. Begin by marking your desired cut line using a pencil or a marker. To ensure accuracy, you can use a ruler or a straight edge as a guide. If you’re cutting a large piece of Perspex, it may be helpful to secure it to a workbench or a sturdy surface using clamps or a vice.

Next, consider using masking tape along the cut line. The tape can help prevent chipping and provide extra stability during the cutting process. Simply apply the tape to the top surface of the Perspex along the marked line, making sure it sticks securely.

By taking these precautions, you’ll create a more stable and defined cutting surface, increasing your chances of achieving clean and accurate cuts.

Mastering the Cutting Technique

The key to successfully cutting Perspex with a hand saw lies in the cutting technique. It’s crucial to use slow and steady strokes, allowing the saw to do the work. Avoid applying excessive pressure or forcefully trying to speed up the process, as this can cause the Perspex to crack or splinter.

Straight cuts are generally easier to achieve with a hand saw, but if you need to make curved or intricate cuts, it may take some practice and patience. For curved cuts, consider using a coping saw, which has a thin blade that allows for more maneuverability.

Remember to take breaks and allow the saw blade to cool down if it becomes hot during the cutting process. Heat can cause the Perspex to melt or warp, leading to imperfect cuts.

Finishing and Smoothing the Edges

Once you’ve made your cuts, you may notice that the edges of the Perspex are rough or uneven. To achieve a clean and polished finish, you can use sandpaper or a fine-grit file to smooth the edges. Start with a coarser grit to remove any rough edges and gradually work your way up to a finer grit to achieve a smooth and polished surface.

Alternatively, you can use a flame polisher or a buffing wheel to heat the edges of the Perspex, melting any imperfections and creating a smooth finish. However, exercise caution when using heat, as it can cause the Perspex to warp or discolor if not done correctly.

By taking the time to finish and smooth the edges, you’ll not only enhance the overall appearance of your project but also reduce the risk of any potential injuries from sharp edges.

Pros and Cons of Cutting Perspex with a Hand Saw

Introduction:

While cutting Perspex with a hand saw is possible, it’s essential to consider the pros and cons before deciding to tackle your project using this method. Understanding the advantages and limitations can help you make an informed decision and ensure the best results.

The Benefits of Cutting Perspex with a Hand Saw

1. Accessibility: One of the primary advantages of using a hand saw is that it’s a tool that most people have readily available. Unlike power tools that may require additional cost or access, a hand saw can be found in many households or can be easily purchased at a reasonable price.

2. Portability: Hand saws are lightweight and easy to transport, making them ideal for situations where power tools may be impractical or unavailable. Whether you’re working on a project at home, in a remote location, or on the go, a hand saw can provide you with the flexibility you need.

3. Control and Precision: While power tools may offer speed and efficiency, using a hand saw allows for greater control and precision. With careful technique and patience, you can achieve accurate and clean cuts without the risk of overpowering the material.

The Limitations of Cutting Perspex with a Hand Saw

1. Time and Effort: Cutting Perspex with a hand saw can be a time-consuming process, especially for larger or more intricate projects. Hand saws require manual effort, and depending on the complexity of the cuts, it may take longer to achieve the desired results compared to using power tools.

2. Skill and Practice: Achieving clean and accurate cuts with a hand saw requires skill and practice. It can be challenging to maintain a consistent cutting speed and pressure, and there is a higher risk of mistakes or imperfections compared to using power tools designed specifically for cutting acrylic materials.

3. Limited Versatility: Hand saws are generally best suited for straight or slightly curved cuts. If your project requires complex or intricate cuts, a hand saw may not be the most suitable tool. In such cases, investing in or borrowing power tools designed for cutting Perspex may be a better option.

Tips for Cutting Perspex with a Hand Saw

Introduction:

Now that you’re familiar with the basics and the pros and cons of cutting Perspex with a hand saw, let’s dive into some helpful tips to ensure success with your cutting project.

Measure Twice, Cut Once

Before making any cuts, take the time to double-check your measurements. Precision is key, and taking a few extra moments to measure and mark your desired cut lines accurately can save you time, effort, and material waste.

Go Slow and Steady

When using a hand saw, it’s important to have patience and maintain a slow and steady pace. Rushing or applying excessive force can result in imperfect cuts, chipping, or cracking. Let the saw do the work, and guide it along the marked line with gentle pressure.

Protect Yourself and Your Material

Always prioritize safety when working with any hand tool, including a hand saw. Wear safety goggles, gloves, and a mask to protect against any potential injuries or debris. Additionally, remember to secure your Perspex properly to prevent slipping or accidental movements during the cutting process.

Practice on Scraps

If you’re new to cutting Perspex with a hand saw, it’s a good idea to practice on scrap pieces before working on your actual project. This will give you a chance to familiarize yourself with the technique, adjust your cutting speed and pressure, and gain confidence before making any cuts that count.

Stay Cool

As mentioned earlier, heat can cause Perspex to melt or warp, resulting in imperfect cuts. To prevent this, take breaks during the cutting process to allow the saw blade to cool down. This will help maintain the integrity of the material and prevent unwanted distortions.

Choosing the Right Hand Saw for Cutting Perspex

Introduction:

Not all hand saws are created equal, and choosing the right one for cutting Perspex can make a significant difference in the quality of your cuts. Here are some hand saw options to consider:

Coping Saw

A coping saw is a versatile hand saw with a thin, narrow blade that is ideal for making curved cuts, intricate designs, or detailed work. The adjustable tension of the blade and the ability to rotate it make the coping saw a popular choice for cutting Perspex. Just make sure to use a fine-toothed blade for better accuracy.

Hacksaw

A hacksaw with a metal-cutting blade can also be used to cut Perspex. Choose a blade with fine teeth to achieve smoother and cleaner cuts. Hacksaws are known for their durability and ability to cut through a variety of materials, making them a reliable option for cutting Perspex.

Jab Saw

While not specifically designed for cutting Perspex, a jab saw can still be used for this purpose. Jab saws feature a short, pointed blade that can easily penetrate the Perspex, making them suitable for making small or starter cuts. However, due to their aggressive saw tooth design, they are best used on thicker Perspex sheets.

Keyhole Saw

Keyhole saws, also known as drywall saws, are designed for making small, intricate cuts in drywall. They can also be used for cutting Perspex, especially when you need to navigate corners or make circular cuts. Keyhole saws have a long, narrow blade with small teeth, allowing for more precise control.

Conclusion

In conclusion, cutting Perspex with a hand saw is indeed possible, but it requires patience, practice, and the right tools. By choosing a fine-toothed saw, properly preparing the Perspex, using the correct cutting technique, and finishing the edges, you can achieve clean, accurate, and professional-looking cuts. While using a hand saw may have its limitations in terms of time and complexity, it offers accessibility, portability, and control that can be valuable in certain situations. Remember to prioritize safety, measure accurately, and practice on scrap pieces before tackling your actual project. With the right approach, cutting Perspex with a hand saw can be a rewarding and successful endeavor.

Key Takeaways: Can I Cut Perspex with a Hand Saw?

- You can cut perspex with a hand saw, but it requires some precautions.

- Choose a saw blade suitable for cutting plastic materials.

- Make sure to secure the perspex firmly before cutting.

- Apply light pressure while cutting to avoid cracking or chipping.

- Use slow and steady strokes, letting the saw do the work.

Frequently Asked Questions

Welcome to our FAQ section where we address common questions regarding cutting perspex with a hand saw. Read on to find answers to your queries!

1. How should I prepare before cutting perspex with a hand saw?

Prior to cutting perspex with a hand saw, there are a few important steps to take. Firstly, ensure you have the right tools – a hand saw with fine teeth and a plastic cutting blade is ideal. Next, make sure to secure your perspex sheet to a stable surface with clamps or vice grips. This helps prevent any accidental movement during the cutting process.

Additionally, mark the cut line on the perspex using a permanent marker or scribe to ensure accuracy. Finally, it is crucial to wear the appropriate safety gear, such as safety glasses and gloves, to protect yourself from any potential accidents. Preparing adequately ensures a smoother and safer cutting experience.

2. Can I cut perspex with a regular wood saw?

While a regular wood saw can theoretically cut perspex, it is not the most ideal tool for the job. Wood saws typically have coarse teeth which may cause the perspex to chip or crack during cutting. It is recommended to use a hand saw specifically designed for cutting plastic and acrylic materials. These saws have finer teeth and a plastic cutting blade, minimizing the risk of damage to the perspex.

Using the right type of hand saw not only ensures a cleaner and smoother cut but also helps extend the lifespan of your saw by reducing wear and tear caused by cutting harder materials such as perspex.

3. What are some tips for achieving a clean cut on perspex with a hand saw?

To achieve a clean cut on perspex with a hand saw, there are a few tips you can follow. Firstly, use long, smooth strokes while cutting rather than applying excessive force. This helps prevent the perspex from cracking or breaking due to too much pressure.

Secondly, consider using a cutting lubricant or a bar of soap to reduce friction and ensure a smoother cutting motion. This can help prevent the saw from getting stuck or binding during the cut. Additionally, take your time and be patient while cutting, allowing the saw to do the work at its own pace.

4. Are there any alternative methods for cutting perspex if I don’t have a hand saw?

If you don’t have access to a hand saw, there are alternative methods for cutting perspex. One option is to use a jigsaw with a fine-toothed blade specifically designed for cutting plastic. Additionally, a rotary tool with a cutting bit or a circular saw with a plastic cutting blade can also be used.

However, it is important to note that these alternative methods may require different techniques and safety precautions, so be sure to familiarize yourself with the specific instructions for each tool and exercise caution during the cutting process.

5. Can I cut complex shapes or curves in perspex with a hand saw?

While it is possible to cut complex shapes or curves in perspex with a hand saw, it can be more challenging compared to cutting straight lines. To cut complex shapes, it is recommended to use a coping saw or a scroll saw with a fine blade designed for cutting plastic.

These saws allow for more precise and intricate cuts, making it easier to create complex shapes or curves in perspex. Take your time and be patient while cutting, as intricate shapes require more attention to detail. Don’t hesitate to practice on a scrap piece of perspex before cutting your desired shape to ensure better accuracy.

Summary

Cutting perspex with a hand saw is possible, but it requires the right technique. You need to use a fine-toothed saw and go slowly to avoid damaging the material. Remember to wear safety goggles and use clamps to secure the perspex while cutting.

Also, consider using a circular saw or a jigsaw if you have access to them. These power tools can make the cutting process easier and more precise. Just make sure to adjust the speed and use the appropriate blade for cutting perspex.

In conclusion, cutting perspex with a hand saw is doable, but it’s important to take precautions, go slowly, and use the right type of saw.