Are you wondering if you can sharpen carbide lathe tools? Well, you’ve come to the right place! Carbide lathe tools are known for their durability and long-lasting edge, but eventually, they’ll need sharpening. So, can you sharpen them? Let’s find out!

If you’re new to the world of lathe tools, you might be wondering if carbide tools can be sharpened like traditional high-speed steel tools. The answer is yes, they can be sharpened, but with a slight twist. You see, carbide tools are incredibly hard and require a different approach when it comes to sharpening.

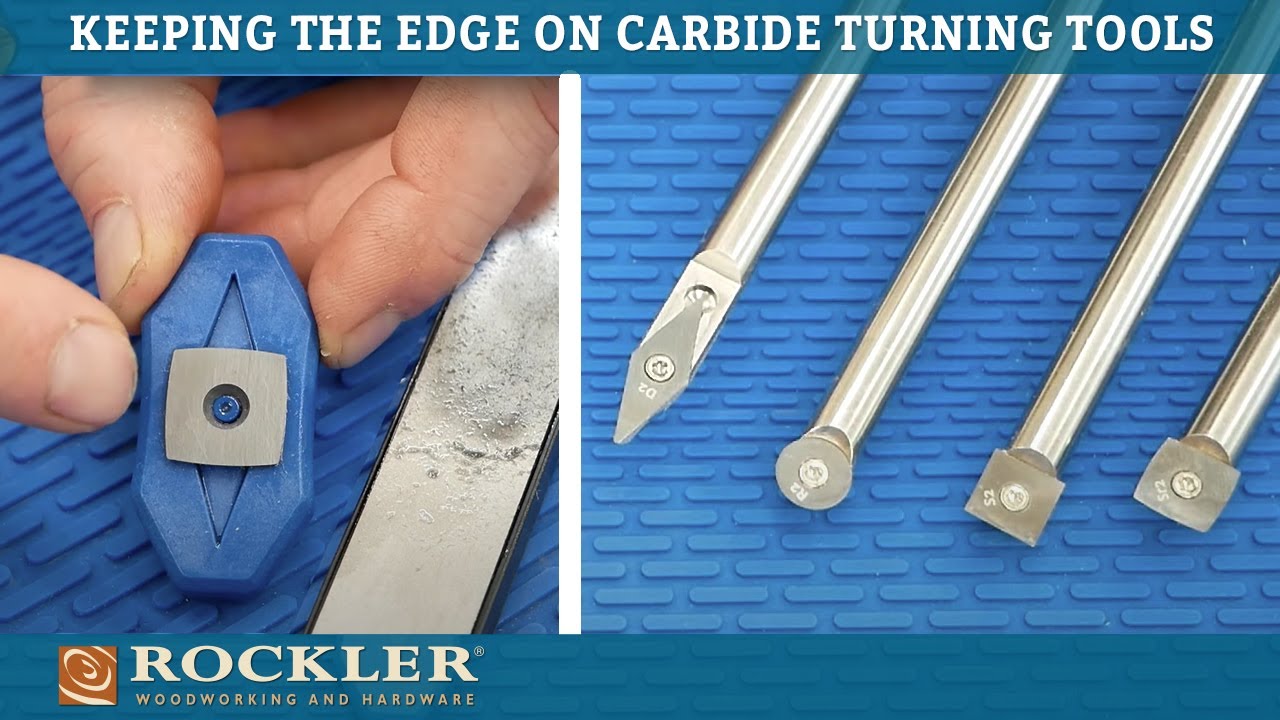

Sharpening carbide lathe tools involves using a diamond grinding wheel or a specialized carbide sharpening system. These tools are designed to grind away the material efficiently, restoring the tool’s cutting edge. So, with the right equipment and know-how, you can definitely sharpen your carbide lathe tools and continue creating amazing projects!

Remember, even though sharpening carbide lathe tools may require some extra steps, it’s a skill that can be learned and mastered with practice. So, don’t hesitate to give it a try and keep those cutting edges sharp for all your lathe projects!

Wondering if you can sharpen carbide lathe tools? Absolutely! Here’s a step-by-step guide to help you out:

- Gather the necessary tools: diamond files, sharpening stones, and a sharpening jig.

- Secure the tool in the sharpening jig.

- Start sharpening by holding the diamond file against the cutting edge at a specific angle.

- Continue filing until the cutting edge is sharp.

- Switch to a sharpening stone for further honing.

- Repeat the process until the desired sharpness is achieved.

With these steps, you’ll be able to sharpen your carbide lathe tools with ease!

Can I Sharpen Carbide Lathe Tools? A Comprehensive Guide

Carbide lathe tools are known for their durability and long-lasting sharpness. However, over time, even the best tools can dull, and sharpening them becomes necessary. Many people wonder if it is possible to sharpen carbide lathe tools, considering their hardness. In this article, we will explore the process of sharpening carbide lathe tools, provide a step-by-step guide, and offer tips and tricks for achieving optimal results.

Understanding Carbide Lathe Tools

Before delving into how to sharpen carbide lathe tools, it is essential to understand their structure and composition. Carbide tools are made from high-quality tungsten carbide, a compound of tungsten and carbon. This material is known for its hardness, making carbide tools highly resistant to wear and providing exceptional cutting performance. Carbide tools are widely used in woodworking, metalworking, and various other applications.

Carbide lathe tools typically come with replaceable carbide inserts, which are indexable for extended tool life. These inserts feature a cutting edge that can become dull over time due to regular use. While carbide tools are known for their durability, sharpening them correctly can significantly extend their lifespan and maintain their cutting performance.

Sharpening Carbide Lathe Tools: Step-by-Step Guide

Sharpening carbide lathe tools requires specific techniques and tools to achieve the desired results. Here is a step-by-step guide to help you sharpen your carbide lathe tools effectively:

- Inspect the tool: Before sharpening, carefully inspect the carbide insert for any damage or chips. If the insert is damaged beyond repair, replace it with a new one.

- Select the right sharpening equipment: Use a diamond wheel or a green silicon carbide wheel specifically designed for sharpening carbide tools. Make sure the wheel is properly aligned and secure.

- Prepare the grinder: Adjust the grinder’s settings according to the manufacturer’s instructions. Set the speed, angle, and depth of cut to ensure precision and safety.

- Secure the tool: Using proper clamping mechanisms, secure the carbide tool to the grinder’s tool rest, ensuring it does not wobble or move during sharpening.

- Start sharpening: Slowly bring the carbide insert into contact with the grinding wheel at the desired angle. Move the tool back and forth across the wheel, applying even pressure. Avoid excessive heat buildup by dipping the tool in cool water periodically.

- Check the progress: Regularly inspect the carbide insert during sharpening to ensure an even and consistent edge. Use a magnifying glass if necessary to spot any imperfections.

- Honing and polishing: Once the desired sharpness is achieved, use a honing stone or diamond file to refine the edge further. Follow up with a polishing compound to give the insert a mirror-like finish.

By following this step-by-step guide, you can effectively sharpen your carbide lathe tools and restore their cutting performance.

Tips for Sharpening Carbide Lathe Tools

Sharpening carbide lathe tools requires precision and attention to detail. Here are some tips to help you achieve optimal results:

- Apply light pressure: When sharpening, it is important to apply light pressure to avoid damaging the cutting edge or overheating the insert.

- Use a lubricant: Applying a lubricant, such as cool water or a dedicated coolant, can help prevent heat buildup and extend the life of the grinding wheel.

- Maintain the right angle: Consistency is key when sharpening carbide tools. Ensure that you maintain the correct angle throughout the sharpening process for optimal cutting performance.

- Frequent inspections: Regularly inspect the carbide insert during sharpening to ensure you are achieving an even and consistent edge. Adjust your technique if necessary.

- Proper storage: After sharpening, store your carbide lathe tools in a clean and dry environment to maintain their sharpness and extend their lifespan.

Benefits of Sharpening Carbide Lathe Tools

Sharpening carbide lathe tools offers several benefits, including:

- Extended tool lifespan: Regular sharpening can significantly extend the life of carbide lathe tools, reducing the need for frequent replacements.

- Improved cutting performance: Sharpened tools provide cleaner and more precise cuts, enhancing the overall quality of your work.

- Cost savings: By sharpening your carbide lathe tools, you can save money on purchasing new tools and inserts.

- Increased efficiency: Sharp tools require less force and produce less heat, resulting in smoother and more efficient machining processes.

Conclusion

Sharpening carbide lathe tools is indeed possible, and with the right techniques and tools, you can achieve excellent results. Regularly maintaining and sharpening your carbide tools will not only preserve their longevity but also ensure optimal cutting performance. By following the step-by-step guide and implementing the provided tips, you can sharpen your carbide lathe tools like a professional and enjoy the benefits of sharp, reliable cutting tools in your projects.

Key Takeaways: Can I Sharpen Carbide Lathe Tools?

- Sharpening carbide lathe tools is possible but requires specialized equipment and techniques.

- Carbide tools can be sharpened using diamond or CBN grinding wheels.

- Proper safety precautions should be taken when sharpening carbide tools, as they can be brittle and prone to shattering.

- Consulting a professional or experienced machinist is recommended for beginners.

- Regular sharpening and maintenance of carbide lathe tools is essential for optimal performance.

Frequently Asked Questions

Welcome to our FAQ section, where we answer common queries about sharpening carbide lathe tools. Whether you’re new to lathe tools or just looking for some guidance, we’ve got you covered. Read on to find answers to your burning questions!

Q1: How often should I sharpen my carbide lathe tools?

It’s important to keep your carbide lathe tools sharp for optimal performance. The frequency of sharpening will depend on how often you use them and the type of material you’re working with. As a general rule of thumb, consider sharpening your tools every 10 to 15 hours of use. However, keep an eye out for signs of dullness, such as chips, rough cuts, or difficulty in shaping the material. If you notice any of these signs, it’s time for a touch-up.

Remember, regular maintenance extends the life of your tools and ensures smoother, cleaner cuts. It’s better to sharpen them a little earlier than have them become excessively dull.

Q2: Can I sharpen carbide lathe tools myself, or should I seek professional help?

While sharpening carbide lathe tools can be challenging, it is possible to do it yourself with the right tools and techniques. However, it’s important to note that carbide is a hard material and requires diamond wheels or specialized sharpening systems. If you’re new to sharpening, or don’t have access to the necessary tools, seeking professional help is advisable.

A professional sharpening service can ensure that your carbide lathe tools are sharpened correctly and will be able to handle the task more efficiently. They have the expertise and equipment to give your tools the best sharpening possible, resulting in longer life and improved cutting performance.

Q3: What are the signs of a dull carbide lathe tool?

There are several signs that indicate a carbide lathe tool is dull and in need of sharpening. One common sign is difficulty in cutting through the material smoothly. If you find yourself applying excessive force or experiencing more resistance than usual, it may be time to sharpen your tool.

Other signs include rough finishes on the material, chattering or vibration during the cutting process, and an increase in the occurrence of chip-outs or tear-outs. These signs not only affect the quality of your work but can also be dangerous. Regularly inspect your carbide lathe tool for any of these indicators and sharpen as needed to maintain optimal performance.

Q4: What is the best way to sharpen carbide lathe tools?

The best way to sharpen carbide lathe tools is to use a diamond wheel or a specially designed sharpening system. These tools are capable of grinding carbide effectively. Follow the manufacturer’s instructions carefully, as different systems may have specific guidelines.

It’s crucial to maintain a consistent angle while sharpening. For most carbide lathe tools, a 45-degree angle is recommended. Take your time and apply even pressure while grinding to achieve a sharp edge. After sharpening, remove any burrs by lightly honing the tool or using a fine-grit sandpaper. Finally, ensure that the tool is properly balanced before returning it to use.

Q5: How can I extend the lifespan of my carbide lathe tools?

To extend the lifespan of your carbide lathe tools, proper maintenance is key. Here are a few tips:

First, always clean your tools after use to remove any debris or buildup. This helps prevent oxidation and corrosion. Secondly, store your tools properly to avoid any physical damage. Consider using protective cases or foam inserts to protect the edges. Lastly, avoid overheating your tools while using them. Excessive heat can reduce the hardness of the carbide and shorten tool life. Take breaks during use to allow the tools to cool down.

By following these maintenance practices and sharpening your tools when necessary, you can ensure that your carbide lathe tools last longer, saving you time and money in the long run.

Summary

Sharpening carbide lathe tools can be tricky because they are very hard and require special techniques. Diamond wheels are the best option for sharpening carbide tools because they can grind through the tough material. It’s important to use proper safety precautions, such as wearing protective eyewear and gloves, when working with carbide tools. It’s also recommended to consult with an experienced professional or reference a reliable guide to ensure you sharpen your carbide lathe tools correctly and effectively.

Remember to always use the right tool for the job and take your time to sharpen your carbide lathe tools properly. With the right technique and equipment, you can keep your carbide tools sharp and prolong their lifespan. Just be sure to follow these tips and stay safe while sharpening your tools. Happy lathe work!