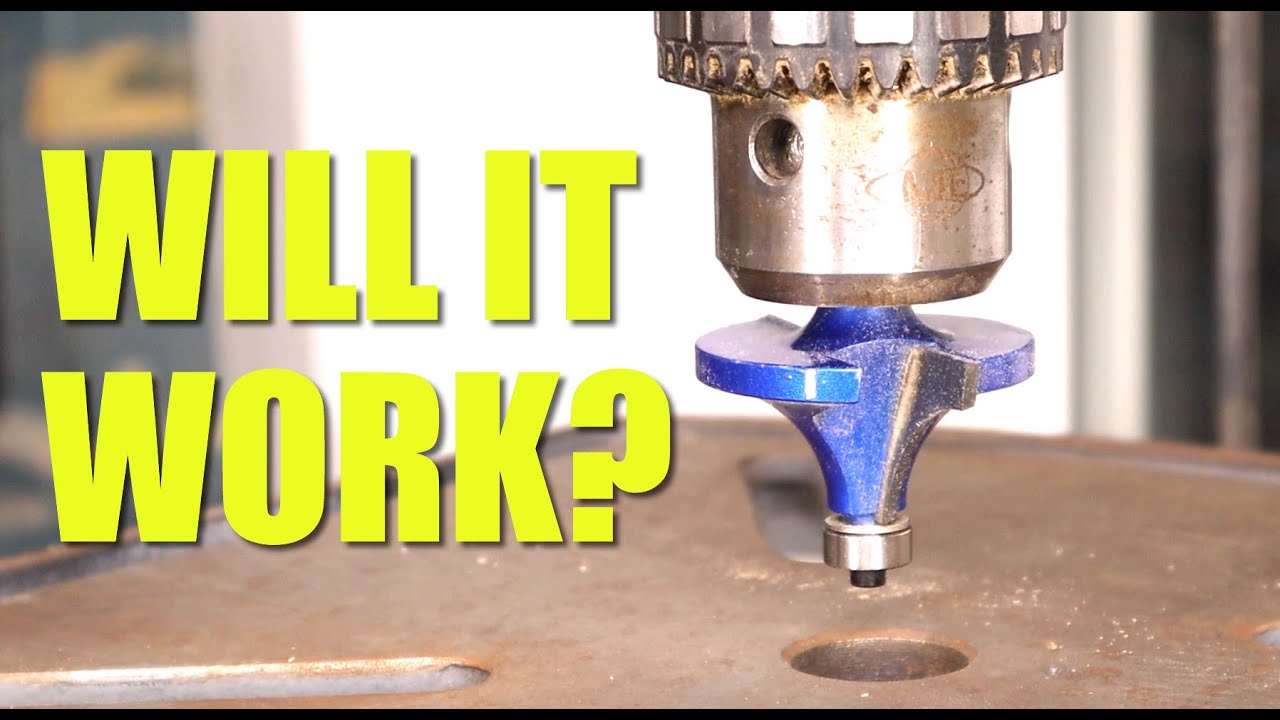

Can you use router bits in a drill press? If you’ve ever wondered about this, you’re in the right place! In this article, we’ll explore whether it’s possible to use router bits with a drill press and what you need to consider before attempting it. So, let’s dive in and find out if you can mix and match these two powerful tools!

Now, you may be thinking, “Why would I want to use router bits in a drill press?” Well, the answer is simple. Router bits come in a wide variety of shapes and sizes, allowing for precise cutting and shaping of materials. So, if you have a drill press and want to expand its capabilities, using router bits might be an attractive option.

But before you get too excited, there are some important things to consider. In the next section, we’ll discuss the key factors that determine whether using router bits in a drill press is feasible and safe. So, stay with us to learn all about it!

While you can technically use router bits in a drill press, it is not recommended. Drill presses are designed for drilling straight holes, while router bits require a rotating motion. The drill press lacks the necessary speed control and stability for router bits, which could lead to unsafe working conditions and potential damage to the equipment. It is best to use dedicated tools for their intended purposes to ensure optimal results and safety.

Can I Use Router Bits in a Drill Press?

Drill presses and routers are both versatile tools that can be used for various woodworking tasks. However, it’s important to understand that they have different purposes and designed functionalities. While it may be tempting to use router bits in a drill press, it’s not recommended and can be potentially dangerous. In this article, we will explore the reasons why using router bits in a drill press is not advisable and provide alternative options for achieving desired woodworking results.

Understanding the Differences between Drill Presses and Routers

Before delving into the reasons why using router bits in a drill press is not recommended, let’s first understand the key differences between these two tools. A drill press is primarily designed for creating precise holes in various materials, such as wood, metal, and plastic. It utilizes a rotating drill bit that moves up and down, controlled by a handle or a lever. On the other hand, a router is specifically built for shaping and trimming wood. It features a high-speed rotating motor that spins router bits to carve intricate patterns, create decorative edges, and make precise cuts.

The main distinction lies in the mechanism and motion of the tools. While a drill press moves vertically to create holes, a router moves horizontally and allows the user to guide the tool along the wood surface. As a result, router bits are designed with a different shape and structure compared to drill bits. The high RPM of router bits requires precision control and maneuverability, which is not provided by a drill press. Attempting to use router bits in a drill press can lead to inefficiency, poor results, and safety hazards.

The Safety Risks of Using Router Bits in a Drill Press

One of the primary reasons why using router bits in a drill press is strongly discouraged is the safety risks involved. Drill presses are not designed to accommodate the high rotational speed required by router bits. Router bits typically operate at speeds of 8,000 to 30,000 RPM, while drill presses typically have a maximum speed of around 3,000 RPM. The significant speed difference can cause the router bit to become imbalanced, leading to vibrations, wobbling, and potentially causing the bit to fly out or break.

In addition to the speed issue, drill presses lack the necessary features and controls for proper handling of router bits. For example, a router often has a plunge base that allows the user to adjust the cutting depth while in use. A drill press does not have this capability, making it difficult to control the depth and potentially leading to uneven or inaccurate cuts. Furthermore, using router bits in a drill press can overload the motor, causing it to overheat and potentially damage the tool.

To ensure the safety of yourself and others, it is crucial to use tools for their intended purposes and follow the manufacturer’s guidelines and specifications. In the case of using router bits, it is recommended to use a dedicated router and router table, which provide the necessary control, stability, and safety features for routing operations.

The Importance of Using the Right Tool for the Job

Using the right tool for the job is essential to achieve high-quality results and ensure safety in woodworking projects. While the temptation to use a drill press as a substitute for a router may arise, it is important to remember that each tool has its own purpose and functionality. Utilizing the wrong tool can lead to inefficiency, poor results, and safety hazards.

Benefits of Using a Dedicated Router

Investing in a dedicated router offers numerous benefits for woodworking enthusiasts. Here are some advantages of using a router for routing tasks:

- Greater control and precision: Routers are specifically designed for precision routing, allowing for detailed and accurate cuts.

- Increased versatility: Routers can be equipped with various router bits, enabling a wide range of shaping, trimming, and cutting options.

- Efficient chip removal: Routers have built-in features for efficient chip removal, preventing clogging and ensuring optimal performance.

- Enhanced safety features: Dedicated routers often come with safety features such as plunge bases, depth stops, and spindle locks, ensuring safe and controlled operation.

- Compatibility with router tables: Using a router table enhances stability, control, and safety during routing operations, especially for larger pieces or repetitive cuts.

Alternative Options for Drilling Precision Holes

While a drill press is not suitable for routing tasks, it excels in drilling precise holes. If you need to drill precision holes in your woodworking projects, here are some alternative options:

- Drill Guides: These portable devices can be attached to a hand drill or a cordless drill, providing enhanced stability and control for precise hole drilling.

- Forstner Bits: Forstner bits are specifically designed for drilling clean and flat-bottomed holes with precision. They are ideal for woodworking projects that require larger diameter holes.

- Spade Bits: Spade bits are economical and versatile tools for drilling holes in wood. They are available in various sizes and can be used with both hand drills and cordless drills.

- Hole Saws: Hole saws are effective for drilling large diameter holes in wood. They consist of a pilot bit and a circular blade, allowing for clean and precise cuts.

By using the appropriate tools and techniques, you can achieve accurate and professional-looking results in your woodworking projects.

Key Takeaways: Can I Use Router Bits in a Drill Press?

- Router bits are not designed for drill presses: Drill presses and routers have different tool designs and functions.

- Poor results and safety risks: Using router bits in a drill press can lead to poor cutting performance and possible accidents.

- Get the right tool for the job: It’s best to use router bits with a router and drill bits with a drill press for optimal results.

- Compatibility issues: The shank sizes and types of router bits and drill bits are different, making them incompatible for cross-usage.

- Enhance safety and performance: Invest in the right tools and use them as intended to ensure safety and achieve the best results.

## Frequently Asked Questions

**Q1: Can I use a router bit in a drill press?**

A: While it is technically possible to use a router bit in a drill press, it is not recommended. Drill presses and routers are designed for different purposes and have distinct features. Drill presses are primarily used for drilling straight holes in various materials, while routers are designed for shaping and profiling wood. Router bits have a different shank size and may not fit securely in a drill press chuck. Additionally, drill presses typically operate at higher speeds, which may cause router bits to spin too fast and lead to unsafe conditions. It’s best to use the right tool for the job and use a router for router bits.

**Q2: How does using a router bit in a drill press affect the quality of work?**

A: When you use a router bit in a drill press, the quality of work may be compromised. Drill presses are not designed to handle the lateral forces required for routing. Without the proper stability and control provided by a router, the results may be inaccurate. The lack of speed adjustment on a drill press can also impact the final outcome. Router bits require specific RPM (rotations per minute) settings for different types of cuts, which drill presses typically cannot accommodate. This can result in burn marks, tear-out, or a poor finish in your workpiece.

**Q3: Are there any safety concerns when using router bits in a drill press?**

A: Yes, using router bits in a drill press can present safety concerns. Drill presses are not designed with the same safety features as routers. Due to the high speeds at which drill presses operate, using router bits can lead to excessive heat buildup, which can cause the bit to become dull or even break. Additionally, drill presses lack the built-in safety mechanisms that routers have, such as enclosures and guards to protect the user from potential injuries. It is crucial to prioritize safety and use the appropriate tools for the task at hand to minimize any risks.

**Q4: Can I achieve the same results with a drill press and a router?**

A: While overlaps in functionality exist between tools, a drill press and a router are designed for different purposes and excel in their respective fields. A drill press is primarily used for drilling precise holes, providing vertical control and accuracy. On the other hand, routers are specialized tools for shaping and profiling wood, offering versatility and depth adjustment. Each tool has unique features that optimize its performance, and attempting to use a drill press to replace a router, or vice versa, may result in compromised precision, finish, and efficiency. It is essential to use the right tool for the specific task to achieve the desired results.

**Q5: What should I do if I need to use a router bit but only have a drill press?**

A: If you need to use a router bit but only have a drill press, the best course of action is to invest in a router or borrow one. Routers are specifically designed for the job and provide the necessary features, such as variable speed control, depth adjustment, and stability, that drill presses lack. If purchasing a router is not an option, consider reaching out to local woodworking groups or friends who may be willing to lend you a router for your project. It’s always best to use the appropriate tool to ensure optimal results and maintain safety.

Summary

Using router bits in a drill press is not recommended because they are designed for different tools. Router bits have a different shank size and rotation speed than a drill press, which can cause safety issues and damage the bits. It’s best to use router bits with a router and drill bits with a drill press to ensure proper and safe operation.

In conclusion, to get the best results and avoid any accidents or damage, it’s important to use the right tools for the job. While it might be tempting to use router bits in a drill press, it’s not worth the risk. Stick to using router bits with a router and drill bits with a drill press, and you’ll have better and safer woodworking experiences.