Are you curious to know if you can sand a lathe? Well, you’ve come to the right place! In this article, we’ll explore the fascinating world of lathes and find out if sanding is a viable option. So, let’s dive in and discover the answer together!

Imagine this: you have a beautiful lathe that you’ve been using for all your woodworking projects. But now, you’re wondering if it’s possible to give it a smooth and polished finish through sanding. Is it a good idea? Can a lathe be sanded? We’ll unravel the mystery in just a moment.

Sanding is a common method used to refine and enhance the appearance of wood surfaces. However, when it comes to lathes, things can get a bit trickier. We’ll explore the reasons behind it and provide you with expert insights and solutions to make the most informed decision. So, let’s roll up our sleeves and get ready to explore the world of lathes and sanding!

1. Turn off the lathe and let it come to a complete stop.

2. Use a sanding block or sandpaper to gently sand the desired area.

3. Start with a coarse grit sandpaper and gradually move to finer grits.

4. Clean the lathe after sanding to remove any dust or debris.

5. Apply a protective finish if desired.

Remember to always prioritize safety and wear protective gear when working with the lathe. Happy sanding!

Can Lathe Be Sanded?

Introduction: Many woodworkers and DIY enthusiasts often wonder if it’s possible to sand a lathe. In this article, we will explore the process of sanding a lathe, its benefits, tips for achieving a smooth finish, and the tools and techniques you will need. Whether you are a professional woodworker or a hobbyist, this article will provide valuable insights into the world of lathe sanding.

Understanding the Lathe Sanding Process

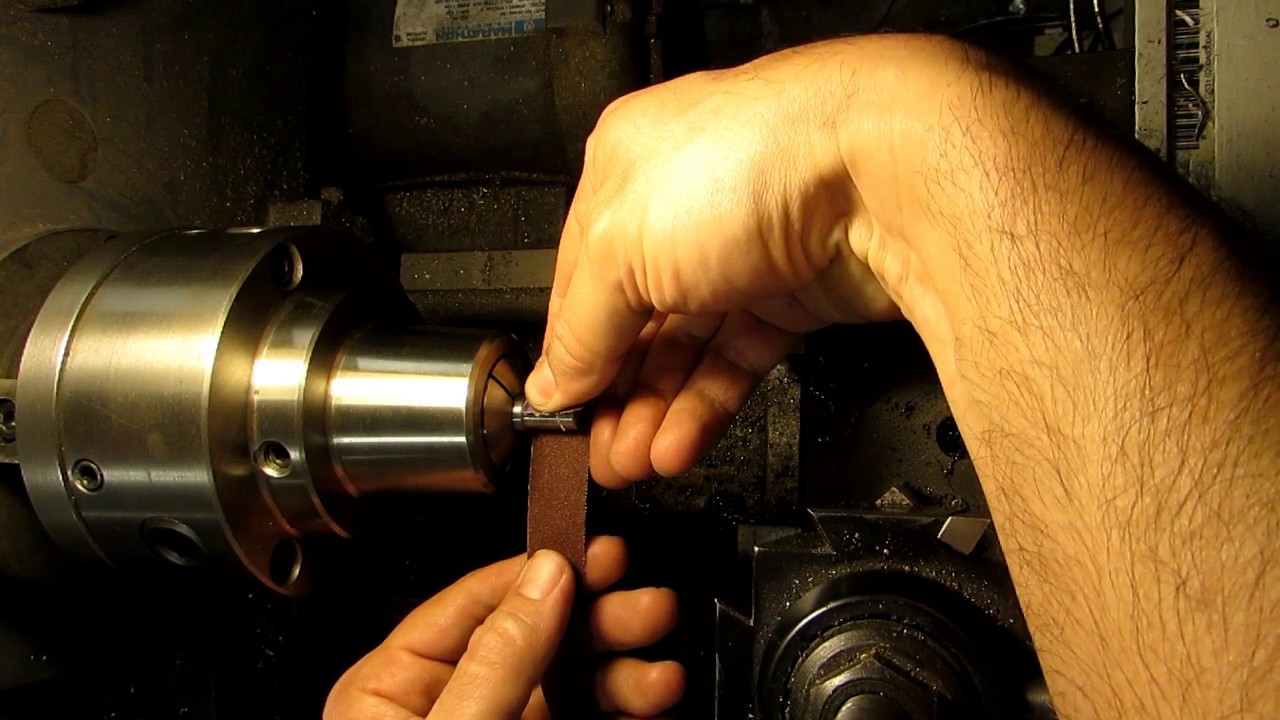

The process of sanding a lathe involves smoothing the surface of the wood as it spins on the lathe machine. Sanding can help remove imperfections, scratches, and tool marks, resulting in a polished and professional-looking finish. It is important to note that while sanding can improve the appearance of a lathe-turned project, it cannot completely fix any flaws in the initial turning or repair structural issues.

When sanding a lathe, it is recommended to start with a rougher grit sandpaper and gradually work your way to finer grits. This progressive approach ensures that you remove any visible blemishes or tool marks and achieve a smooth surface. The key is to make slow and even passes, allowing the sandpaper to do the work. It is crucial to keep the sandpaper moving and avoid dwelling on one spot for too long to prevent uneven sanding or burning the wood.

Additionally, consider using sanding sealer or sanding paste to enhance the smoothness of the surface. These products can fill in any remaining imperfections and create a solid foundation for applying finishes such as varnish or lacquer. Proper sanding techniques, patience, and attention to detail are essential for achieving a professional-looking finish on a lathe project.

The Tools and Materials You’ll Need

When sanding a lathe, you’ll need a few essential tools and materials to ensure a successful outcome. Here are some items you should consider:

- Sanding paper or sanding pads of various grits (ranging from coarse to fine)

- A lathe with a securely mounted project

- Protective equipment, such as safety goggles and a dust mask

- A sanding sealer or sanding paste for a smoother finish

- A sanding mandrel or sanding pad attachment for the lathe

- A clean and lint-free cloth for wiping away dust and debris

These tools and materials will help you achieve the desired results and ensure a safe and efficient sanding process. It’s important to use high-quality sandpaper and take appropriate safety precautions while working with power tools.

The Benefits of Sanding a Lathe

Sanding a lathe offers several benefits for woodworkers and DIY enthusiasts. Here are some advantages of incorporating sanding into your lathe projects:

- Enhanced appearance: Sanding helps create a smooth and polished surface, enhancing the overall appearance of your lathe-turned project.

- Improved finish: By removing imperfections and tool marks, sanding prepares the wood for applying finishes such as varnish or lacquer, resulting in a professional-looking end product.

- Refinement of details: Sanding allows you to refine the details of your design, bringing out the intricate patterns and contours of the wood.

- Greater versatility: By sanding your lathe projects, you can experiment with different finishes and achieve various levels of glossiness or texture.

These benefits make sanding an integral part of the lathe turning process, enabling woodworkers to create stunning and high-quality projects.

Tips for Achieving a Smooth Finish

To achieve a smooth finish when sanding a lathe, here are some tips to consider:

- Start with the right grit: Begin sanding with a coarse grit sandpaper to eliminate any visible blemishes or tool marks. Gradually progress to finer grits for a smoother surface.

- Apply consistent pressure: Apply even pressure to the sandpaper while it is in contact with the spinning wood. This ensures an even sanding result.

- Use varying sanding motions: Experiment with different sanding motions, such as straight, circular, or diagonal, to ensure that you cover all areas and achieve an even finish.

- Regularly clean the sandpaper: Dust and debris can accumulate on the sandpaper, reducing its effectiveness. Clean the sandpaper regularly or replace it when necessary.

- Inspect your work: After each sanding pass, carefully inspect the surface for any imperfections. Address them before proceeding to the next grit level.

By following these tips, you can significantly improve your sanding results and achieve a flawlessly smooth finish on your lathe projects.

Conclusion

In conclusion, sanding a lathe can indeed be done and offers a range of benefits for woodworking projects. By understanding the process, using the right tools and materials, and following proper techniques, you can achieve a polished and professional-looking finish on your lathe-turned creations. Remember to start with a coarse grit sandpaper and gradually progress to finer grits, keep the sandpaper moving, and inspect your work at each stage. By incorporating these practices, you can elevate the quality of your lathe projects and create stunning woodwork pieces to be proud of.

Key Takeaways – Can Lathe be Sanded?

In simple terms, a lathe is a machine used for shaping wood or metal. Unfortunately, sanding a lathe is not recommended because it can damage the machine and compromise its functionality.

- Sanding a lathe can cause damage to the delicate components, such as the bearings and motor.

- It is best to use other methods like scraping or using sandpaper by hand to shape the wood or metal on the lathe.

- Regular maintenance and cleaning are important to keep the lathe functioning properly.

- If you need to smooth or refine a finished project, it is advised to use sandpaper or other appropriate tools outside of the lathe.

- Always prioritize safety when working with machinery, including lathes.

Frequently Asked Questions

Welcome to our FAQ section where we answer common questions about the process of sanding a lathe. Find out more about whether a lathe can be sanded in the questions below!

1. How can I sand a lathe?

To sand a lathe, you’ll need a few essential tools and supplies. Begin by cleaning the lathe and removing any loose debris or dust. Next, use sandpaper or sanding pads to gently sand the lathe in the direction of the wood grain. Start with a coarse grit sandpaper and gradually move to finer grits for a smoother finish. Be sure to work methodically and evenly across the lathe to avoid uneven sanding. Finally, finish by wiping off any remaining dust and apply an appropriate finish to protect the wood.

It’s important to note that sanding a lathe requires care and patience, as you don’t want to remove too much material or damage the lathe. Follow safety precautions such as wearing protective eyewear and gloves, and take your time to achieve the desired result.

2. Can I sand a metal lathe?

Sanding a metal lathe involves a slightly different process compared to sanding a wooden lathe. Instead of using sandpaper, you’ll need to use specially designed sanding discs or abrasive pads that are suitable for metal surfaces. These abrasive materials are usually made of aluminum oxide and are available in various grits.

Before sanding a metal lathe, it’s crucial to make sure it is clean and free from any grease or dirt. You should also secure the lathe in a vise or another sturdy fixture to prevent it from moving during sanding. Start with a lower grit abrasive pad to remove any rough surfaces or imperfections, and then gradually move to higher grits for a smoother finish. Take your time and work evenly across the metal surface, checking your progress frequently to avoid over-sanding.

3. What are the benefits of sanding a lathe?

Sanding a lathe offers several benefits, regardless of whether it’s made of wood or metal. Firstly, sanding helps to remove rough patches, uneven surfaces, or imperfections, resulting in a smoother finish. It also allows for better adhesion of finishes that can enhance the appearance of the lathe. Additionally, sanding can help to reveal the natural beauty of the wood or metal by removing dull or damaged outer layers.

Moreover, when sanding a wooden lathe, it can also help to improve the accuracy and precision of turning projects. By meticulously sanding the surface, you can achieve tighter tolerances and a more refined final product. Overall, sanding a lathe is a crucial step in creating high-quality and visually pleasing woodturning or metalworking projects.

4. Can I sand my lathe without removing it from the machine?

Sanding a lathe without removing it from the machine is possible to some extent, depending on the design and accessibility of the lathe. However, it is generally recommended to remove the lathe from the machine for thorough sanding. This allows you to reach all areas of the lathe more easily and ensures a more uniform and consistent sanding process.

If you need to sand specific parts of the lathe that are difficult to access, you can use specialized sanding attachments or flexible sanding tools to reach those areas. These tools can help you sand hard-to-reach corners or curves while the lathe is still mounted on the machine. However, be cautious and make sure not to damage any components or leave any areas unsanded by using these methods.

5. What precautions should I take while sanding a lathe?

When sanding a lathe, it’s important to take certain precautions to ensure your safety and the longevity of the lathe. First and foremost, always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and a dust mask to protect yourself from potential hazards.

Make sure to secure the lathe properly either by mounting it securely on a workbench or using clamps to hold it in place. This will prevent the lathe from moving or vibrating excessively during the sanding process. Also, be mindful of the grit of the sandpaper or abrasive pad you use, as using overly coarse grits or excessive pressure can result in removing too much material, causing damage to the lathe. Finally, clean the lathe thoroughly after sanding to remove any residual dust or particles that could affect future applications of finishes or tools.

Sanding Wood Bowl Finish How To Sand Woodturning Video

Summary

Can a lathe be sanded? No, sanding a lathe is not recommended. It can damage the lathe’s metal parts and affect its performance. Instead, use appropriate cleaning methods and lubricants to maintain the lathe’s smooth operation.

Avoid using sandpaper or abrasive materials on the lathe to prevent scratches, rust, and other forms of damage. Regularly clean and oil the lathe to keep it in good working condition. Remember, proper maintenance is key to extending the lifespan of your lathe and ensuring optimal performance.