Can plywood be used for shoring? If you’re curious about whether plywood can be a reliable choice for shoring up structures, you’ve come to the right place. In this article, we’ll explore the potential of plywood for shoring and provide you with all the information you need.

Now, you might be wondering what shoring is. Well, shoring is the process of supporting a structure to prevent collapse or to provide stability during construction or repair work. It plays a crucial role in ensuring the safety of workers and the integrity of the building.

But can plywood, a material commonly associated with furniture or DIY projects, be strong enough for shoring? Let’s dive in and find out together!

Can Plywood be Used for Shoring?

When it comes to construction projects, shoring is a crucial step to ensure the safety and stability of a structure. One material that is often considered for shoring purposes is plywood. Plywood is a versatile building material known for its strength and durability. But can plywood really be used for shoring? In this article, we will explore this question in detail, examining the benefits, limitations, and considerations of using plywood for shoring. So, let’s dive in and find out if plywood is a suitable choice for your shoring needs.

The Strength of Plywood for Shoring

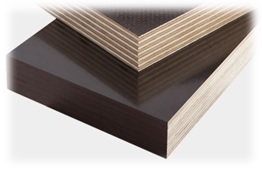

Plywood is made by bonding multiple layers of thin wood veneers together, resulting in a strong and stable panel. This construction method gives plywood excellent structural integrity, making it capable of handling heavy loads.

For shoring applications, plywood can be a reliable choice for temporary support. It can provide lateral stability and distribute loads evenly, reducing the risk of structural failure. Plywood’s high strength-to-weight ratio also makes it easier to handle and install compared to other materials.

However, it’s important to note that plywood has its limitations. While it can handle substantial loads, its load capacity may not match that of more specialized shoring materials such as steel beams or concrete forms. Therefore, when considering plywood for shoring, it is crucial to assess the specific requirements of your project and consult with a structural engineer to ensure it is the right choice.

The Benefits of Using Plywood for Shoring

Despite its limitations, plywood offers several benefits that make it a popular choice for shoring applications:

- Cost-Effective: Plywood is generally more affordable than specialized shoring materials, making it an attractive option for projects with tight budgets.

- Readily Available: Plywood is widely available in various sizes and thicknesses, making it easily accessible for shoring needs.

- Easy to Install: Plywood can be cut and shaped to fit the required dimensions, making it versatile and easy to work with during installation.

- Reusable: Plywood can be disassembled and reused for multiple projects, providing cost savings and environmental benefits.

These advantages, combined with plywood’s strength and stability, make it a viable option for temporary shoring needs in many construction scenarios.

Considerations and Tips for Using Plywood for Shoring

While plywood can be a suitable choice for shoring, it is important to consider the following factors:

- Load Capacity: Assess the estimated loads and consult with a structural engineer to ensure that plywood can handle the required weight.

- Proper Sizing: Use the appropriate thickness and size of plywood based on the shoring requirements and engineering guidelines to ensure stability.

- Fastening and Support: Secure the plywood panels with appropriate fasteners, such as screws or nails, and provide additional support using bracing or props as needed.

- Weather Protection: Consider the exposure of the shoring system to the elements and apply protective coatings or coverings to prevent damage and deterioration.

By taking these considerations into account and following best practices, plywood can be effectively used for temporary shoring, improving safety and stability during construction.

Plywood Vs. Other Shoring Materials

While plywood has its advantages, it’s essential to compare it to other shoring materials to make an informed decision. Here’s how plywood stacks up against other commonly used shoring materials:

| Material | Strength | Cost | Availability | Installation |

|---|---|---|---|---|

| Plywood | Good | Low | High | Easy |

| Steel Beams | Excellent | High | Medium | Complex |

| Concrete Forms | Excellent | Medium | Medium | Complex |

As seen in the comparison table above, plywood offers a good balance of strength, cost-effectiveness, availability, and ease of installation. However, for projects with higher load requirements or specialized needs, materials like steel beams or concrete forms may be more appropriate.

Conclusion

So, can plywood be used for shoring? The answer is yes, under the right circumstances. Plywood’s strength, affordability, and easy installation make it a viable option for temporary shoring needs in many construction projects. However, it’s important to assess the specific requirements of your project, consult with a structural engineer, and consider other shoring materials if needed. By following best practices and guidelines, plywood can provide the necessary support and stability during construction, contributing to a safe and successful build.

Can plywood be used for shoring?

Yes, plywood can be used for shoring in certain situations.

- Plywood can provide temporary support in construction projects.

- It is commonly used for shoring formwork in concrete construction.

- Plywood shoring is cost-effective and easy to install.

- However, plywood may not be suitable for heavy or long-term shoring.

- Proper engineering and supervision are essential when using plywood for shoring.

Frequently Asked Questions

Plywood has various applications in construction, but can it be used for shoring? Read on to find out.

1. How does plywood compare to other materials when it comes to shoring?

When compared to other materials, plywood offers several advantages for shoring purposes. It is lightweight, making it easier to handle and transport, while still providing sufficient strength for temporary support. Plywood is also readily available, cost-effective, and can be easily cut into the desired shapes and sizes. Additionally, plywood is versatile and can be used in various shoring applications.

However, it’s important to note that plywood may not be ideal for every shoring situation. Factors such as load capacity, site conditions, and specific project requirements should be considered when determining the suitability of plywood for shoring. Consulting with a structural engineer or construction professional is recommended to ensure the proper selection of materials.

2. What are the key considerations when using plywood for shoring?

When using plywood for shoring, there are several important factors to consider. Firstly, you need to determine the load capacity required for the shoring system based on the weight it will be supporting. This will help ensure that the plywood used is of adequate thickness and quality to handle the load.

Site conditions and duration of the shoring project should also be taken into account. Moisture levels, temperature, and exposure to sunlight can affect the performance of plywood. It’s crucial to choose plywood that is suitable for the specific environmental conditions of the site. Additionally, if the shoring will be in place for a prolonged period, you may need to consider the potential for swelling, warping, or decay over time.

3. Can plywood be used for both vertical and horizontal shoring?

Yes, plywood can be used for both vertical and horizontal shoring. For vertical shoring, plywood sheets can be installed against walls to provide temporary support. This can be useful when carrying out construction or renovation work that requires stabilizing existing structures. For horizontal shoring, plywood panels can be laid across joists or beams to distribute the load and provide support for workers and equipment.

However, it’s important to ensure that the plywood used is of sufficient thickness and strength to handle the anticipated loads. Consulting with a structural engineer or construction professional is essential to ensure the safety and effectiveness of the shoring system.

4. Are there any limitations to using plywood for shoring?

While plywood can be a suitable material for shoring, there are some limitations to consider. Plywood is not as strong as certain metallic or composite materials used specifically for shoring systems. Therefore, it may not be appropriate for heavy-duty or long-term shoring applications where high load capacities are required.

Additionally, plywood is susceptible to degradation when exposed to moisture or extreme environmental conditions. To mitigate these risks, proper maintenance and periodic inspections are necessary. Regular checks should be conducted to identify any signs of damage or deterioration that could compromise the structural integrity of the shoring system.

5. Are there any safety precautions to keep in mind when using plywood for shoring?

When using plywood for shoring, it’s important to follow safety guidelines to ensure the well-being of workers and the stability of the structure. Adequate bracing and support should be provided to prevent accidental collapse. Additionally, workers should be trained on the proper installation and removal procedures for plywood shoring systems.

Inspecting plywood panels for damage, such as cracks or splits, before use is vital to ensure their structural integrity. Furthermore, regular inspections during the shoring project should be conducted to identify any signs of wear, decay, or deformation. It’s crucial to address any issues promptly and replace damaged plywood to maintain a safe working environment.

Summary

Using plywood for shoring can be risky because it may not provide enough support. Plywood is not designed for heavy loads and can easily break under pressure. It’s safer to use materials specifically designed for shoring, like steel or concrete, to ensure stability and prevent accidents. Always prioritize safety when choosing materials for shoring projects.