Did you know that power tools have become an essential part of many DIY projects? Whether you’re fixing something around the house or working on a creative endeavor, power tools can make the job much easier. But here’s a question for you: can power tools damage electronics? Well, let’s find out!

You see, power tools are designed to be robust and powerful, capable of cutting, drilling, and shaping various materials. However, electronics are delicate and sensitive. So, it’s important to understand the potential risks involved in using power tools around electronics.

Now, before we dive into the details, let me assure you that you don’t need to worry too much. With some precautions and know-how, you can safely use power tools without damaging your precious electronics. So, let’s explore the fascinating world where power tools and electronics intersect!

Can Power Tools Damage Electronics?

Power tools are a staple in many workshops and households, providing the means to tackle a wide range of tasks efficiently. However, when it comes to using power tools around electronic devices, there is a concern about potential damage. This article will explore whether power tools can indeed damage electronics and provide essential insights, safety tips, and precautions to keep your electronic devices safe.

The Impact of Vibrations on Electronics

Vibrations generated by power tools can potentially impact the delicate internal components of electronic devices. The constant shaking and oscillation caused by power tools can lead to loose connections, damaged solder joints, and even dislodged or broken components. This is especially true for more sensitive electronics such as circuit boards, microchips, and delicate wiring.

To avoid potential damage, it is crucial to minimize the exposure of electronic devices to excessive vibrations. Consider using anti-vibration mats or padding to absorb and reduce shocks caused by power tools. Additionally, when working in close proximity to electronics, opt for power tools with built-in vibration reduction systems or features to minimize the risk of damage.

In situations where it is not possible to avoid using power tools near electronics, it is advisable to disconnect the devices from power sources and remove any detachable components or sensitive parts beforehand. This will help reduce the chances of damage caused by vibrations.

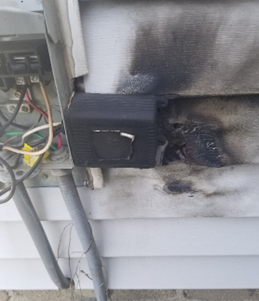

The Risk of Electrical Surges

Another potential hazard when using power tools near electronics is the risk of electrical surges. Power tools, especially those with high power requirements, can cause fluctuations in the electrical current, leading to surges that can damage electronic devices.

To mitigate the risk of electrical surges, it is essential to use surge protectors or uninterruptible power supply (UPS) systems when working with power tools around electronics. These devices help regulate the flow of electricity and provide protection against sudden voltage spikes that could harm your electronic devices. It is important to note that surge protectors and UPS systems should be properly rated for the power tools and electronics in use to ensure maximum effectiveness.

Additionally, before connecting any power tools to electrical outlets or extension cords, make sure they are in good condition and able to handle the power requirements of the tools being used. Faulty or insufficient wiring can increase the likelihood of electrical surges and potential damage to your electronics. Regular inspection and maintenance of power cords, outlets, and extension cords can help prevent these issues.

Heat Generation and Electronics

One often overlooked aspect of power tool usage is the heat generated during operation. Some power tools, such as drills, sanders, and saws, can produce significant amounts of heat, which can pose a risk to nearby electronic devices.

When using power tools, especially those that generate substantial heat, it is crucial to maintain a safe distance between the tool and the electronics to prevent heat transfer. The heat from power tools can cause damage to sensitive components, lead to overheating or warping of plastic casings, and even result in electrical malfunctions.

Furthermore, proper ventilation and cooling are essential when operating power tools in confined spaces or around electronics. Adequate airflow can help dissipate the heat generated by the tools, reducing the risk of damage to nearby electronic devices. If necessary, consider using additional cooling methods such as fans or positioning the tools near open windows or doors to enhance airflow.

Tips for Protecting Electronics from Power Tool Damage

Now that we have explored the potential risks posed by power tools to electronics, let’s delve into some practical tips to help protect your devices:

- Always disconnect electronic devices from power sources before using power tools nearby.

- Consider using anti-vibration mats or padding to minimize the impact of vibrations on electronics.

- Use surge protectors or UPS systems to regulate electrical current and protect against surges.

- Ensure power cords, outlets, and extension cords are in good condition and properly rated for the power tools in use.

- Maintain a safe distance between power tools and electronics to prevent heat transfer.

- Provide adequate ventilation and cooling when operating power tools near electronics.

- When in doubt, consult the manufacturer’s instructions or seek professional advice for specific electronics or power tool combinations.

The Benefits of Using Power Tools Safely

While there are potential risks associated with using power tools around electronics, it is important to remember the many benefits these tools bring when used safely. Power tools allow for increased efficiency, precision, and productivity, enabling users to complete tasks more quickly and effectively. By following the recommended safety measures and precautions, individuals can harness the advantages of power tools while keeping their valuable electronic devices protected.

Essential Safety Equipment for Power Tool Usage

When it comes to working with power tools, ensuring the safety of both yourself and your surroundings should be a top priority. In addition to practicing safe operating procedures and adhering to recommended guidelines, using appropriate safety equipment can significantly reduce the risk of accidents and injuries. This section will highlight some essential safety equipment to consider when using power tools.

Protective Eyewear

One of the most critical pieces of safety equipment to wear when using power tools is protective eyewear. Power tools can generate debris, dust, and even sparks that can cause eye injuries. It is vital to wear safety glasses or goggles that are specifically designed to provide impact resistance and protect your eyes from potential hazards. Make sure to choose eyewear that fits comfortably and securely, with lenses that meet the required safety standards.

Hearing Protection

Power tools can generate high levels of noise, which can lead to hearing damage over time. To protect your hearing, it is advisable to wear appropriate hearing protection, such as earmuffs or earplugs, when operating power tools. Select hearing protection devices that offer a suitable Noise Reduction Rating (NRR) and ensure a proper fit to effectively block out the noise. Regularly inspect and replace hearing protection equipment that shows signs of wear or deterioration.

Respiratory Protection

When working with power tools that generate dust, fumes, or airborne particles, respiratory protection is crucial. Depending on the nature of the work and the potential contaminants, wearing a respirator or dust mask can help prevent inhalation of harmful substances. Select respiratory protection devices that are appropriate for the type and concentration of airborne hazards present. Follow the manufacturer’s instructions for maintenance and replacement to ensure maximum effectiveness.

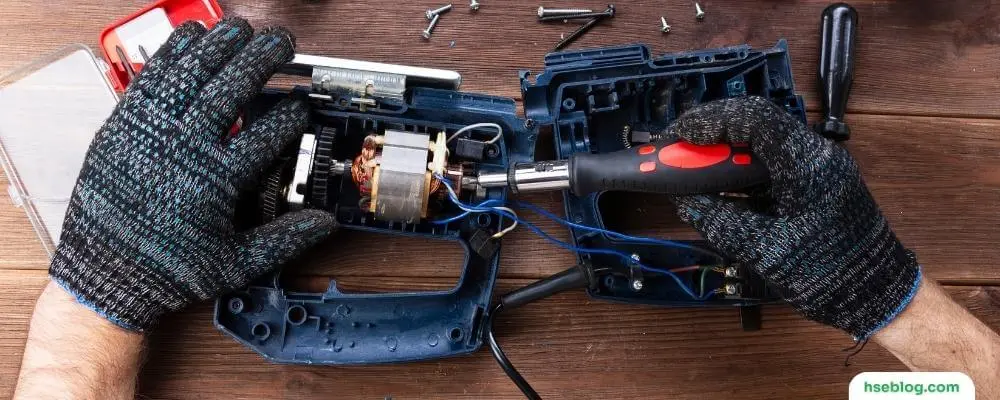

Protective Gloves

Using power tools can expose your hands to potential hazards, including cuts, abrasions, and burns. Wearing protective gloves can help prevent such injuries by providing a barrier between your hands and the tool or workpiece. Choose gloves that offer appropriate protection for the specific tasks and power tools involved. Consider factors such as cut resistance, grip, dexterity, and comfort when selecting gloves. Inspect gloves regularly for signs of wear or damage, and replace them as needed.

Protective Footwear

A sturdy pair of safety shoes or boots is essential when using power tools. They provide protection against potential falling objects, sharp materials, and impacts. Safety footwear should meet necessary safety standards, such as having reinforced toes and slip-resistant soles. Ensure that the shoes or boots fit properly, are comfortable to wear for extended periods, and are in good condition. Regularly inspect and replace footwear that shows signs of wear or damage.

Protective Clothing

Wearing appropriate protective clothing can help minimize the risk of injuries when working with power tools. Consider wearing long-sleeved shirts, long pants, or coveralls made of thick, durable materials to provide a layer of protection against cuts, burns, and other potential hazards. Avoid loose-fitting clothing that can get caught in moving parts of power tools. Additionally, if working in environments with extreme temperatures or exposure to hazardous substances, specialized protective clothing may be necessary.

Tool-Specific Safety Equipment

Certain power tools require additional safety equipment to ensure safe operation. For example, when using a chainsaw, a protective helmet with a face shield and hearing protection is essential. When operating a router, a dust extraction system can help minimize the inhalation of fine particles. Always consult the manufacturer’s instructions and recommendations for specific power tools to identify any tool-specific safety equipment that should be used.

Proper Training and User Manuals

Regardless of the safety equipment employed, it is crucial to have proper training and an understanding of the specific power tools being used. Read and familiarize yourself with the user manuals and safety guidelines provided by the tool’s manufacturer. Attend training courses or workshops if available to learn safe operating practices and techniques. Regularly refresh your knowledge and stay up-to-date with any updates or changes in safety regulations.

Common Power Tools and Their Potential Risks to Electronics

Power tools are available in a wide range of types and functions, each with its own potential risks when it comes to using them around electronic devices. This section will highlight some common power tools and address their potential hazards.

Drills

Drills are a staple in any toolbox, allowing users to create holes for various purposes. However, when using drills near electronics, there is a risk of generating excessive vibrations and potentially damaging delicate components. It is important to exercise caution and take necessary precautions to mitigate this risk.

Tips to protect electronics when using drills:

- Disconnect electronics from power sources before using a drill in close proximity.

- Use anti-vibration mats or padding to reduce vibrations.

- Maintain a safe distance between the drill and electronic devices.

Saws

Saws, whether circular, reciprocating, or jigsaws, excel at cutting through a variety of materials. However, the intense vibrations and potential heat generated by saws can pose risks to nearby electronics. Careful handling and proper safety measures are essential when using saws around sensitive electronic devices.

Tips to protect electronics when using saws:

- Disconnect electronics from power sources.

- Ensure a safe distance between the saw and electronic devices.

- Use anti-vibration mats and cooling measures when necessary.

Sanders

Sanders are commonly used to achieve smooth surfaces and remove material quickly. However, the high-speed rotation and abrasion caused by sanders can generate excessive heat and debris that pose a risk to electronics. Implementing appropriate safety precautions is crucial to prevent damage to nearby electronic devices.

Tips to protect electronics when using sanders:

- Disconnect electronics and remove detachable parts.

- Maintain a safe distance between the sander and electronic devices.

- Ensure proper ventilation and cooling.

Grinders

Grinders are powerful tools used for cutting, grinding, and polishing various materials. The sparks, intense vibrations, and potential heat generated by grinders can be detrimental to electronic devices. Taking preventive measures and using appropriate safety equipment are crucial when using grinders in proximity to electronics.

Tips to protect electronics when using grinders:

- Disconnect electronics and remove detachable parts.

- Use anti-vibration mats and cooling measures.

- Maintain a safe distance between the grinder and electronic devices.

Nail Guns

Nail guns provide a convenient and efficient way to drive nails into different materials. However, the powerful impact and vibrations generated by nail guns can potentially damage nearby electronic devices. It is essential to take necessary precautions to reduce the risk of harm to electronics.

Tips to protect electronics when using nail guns:

- Disconnect electronics from power sources.

- Maintain a safe distance between the nail gun and electronic devices.

- Use anti-vibration mats or padding.

Rotary Tools

Rotary tools offer versatility and precision for various tasks. However, the small size and high-speed rotation can lead to the dispersal of fine particles and debris that may damage electronics. Protective measures are crucial when using rotary tools near sensitive electronic devices.

Tips to protect electronics when using rotary tools:

- Disconnect electronics and remove detachable parts.

- Create a barrier or shield to prevent debris from reaching electronic devices.

- Maintain a safe distance between the tool and electronic devices.

Avoiding Power Tool Damage to Electronics

To summarize, power tools can potentially damage electronics due to vibrations, electrical surges, and heat generation. However, by following necessary safety precautions and implementing protective measures, users can minimize the risk of harm to electronic devices. Always disconnect electronics from power sources, use anti-vibration mats or padding, employ surge protectors or UPS systems, maintain a safe distance, and ensure proper ventilation and cooling. Additionally, selecting the right safety equipment and being mindful of the potential risks of specific power tools will further help safeguard electronics from any damage.

Can Power Tools Damage Electronics?

- 1. Power tools can potentially damage electronics if used improperly or without proper precautions.

- 2. Connecting power tools to the same circuit as electronic devices can lead to power surges and voltage fluctuations, which can harm the electronics.

- 3. Vibrations caused by power tools can loosen internal components of electronic devices, leading to malfunction or damage.

- 4. It is important to use surge protectors or separate circuits for powering electronic devices and operating power tools.

- 5. Proper grounding and insulation of power tools and electrical cords can help prevent damage to electronics.

Frequently Asked Questions

When using power tools, it’s important to know how they can impact our electronics. Here are some common questions related to power tools and potential electronic damage.

1. Can power tools cause damage to electronics?

Yes, power tools have the potential to cause damage to electronics. Power tools generate vibrations and electrical interference that can affect the delicate components and circuitry of electronic devices. The vibrations can cause loose connections or dislodgment of components, while electrical interference can disrupt the normal functioning of electronic devices.

To minimize the risk of damage, it’s advisable to keep power tools away from electronic devices and utilize proper grounding techniques when using power tools near electronic equipment. Additionally, using surge protectors or voltage regulators can help safeguard your electronics from power tool-related damage.

2. Which power tools are more likely to cause damage to electronics?

Power tools that generate high vibrations or emit strong electromagnetic fields are more likely to cause damage to electronics. Tools like jackhammers, electric hammers, and powerful drills produce significant vibrations that can impact nearby electronic devices. Similarly, power tools that generate electrical sparks, such as angle grinders or plasma cutters, can potentially damage electronics through electrical interference.

It’s important to exercise caution when using these tools in close proximity to electronic devices. If possible, move the electronics to a safer location or ensure proper insulation and grounding to minimize the risk of damage.

3. How can I protect my electronics from power tool damage?

To protect your electronics from power tool damage, there are several steps you can take. Firstly, store your electronic devices in a secure location away from areas where power tools are being used to avoid any accidental damage or disturbance. If you need to use power tools near electronics, disconnect them from power sources and ensure they’re properly insulated and shielded.

Using surge protectors or voltage regulators can help safeguard electronic devices from power tool-related power surges. Additionally, employing proper grounding techniques can mitigate the risk of electrical interference. It’s also a good practice to check your electronic devices after power tool usage for any signs of damage or malfunction.

4. Can power tool damage be repaired?

Whether power tool damage to electronics can be repaired depends on the extent and nature of the damage. In some cases, minor issues like loose connections or dislodged components can be fixed relatively easily. However, more severe damage to the circuitry or internal components may require professional repair or replacement of the affected parts.

If your electronic device has been damaged by a power tool, it’s advisable to consult a professional technician or contact the manufacturer for guidance on repair options. Attempting repairs without proper knowledge or expertise can potentially cause further damage or void any warranty on your electronic device.

5. Are there any precautions to take while using power tools around electronics?

Absolutely! When using power tools near electronics, there are several precautions you should take. Firstly, ensure that the power tools you are using are in good working condition and well-maintained, as faulty tools can increase the risk of damage to electronics.

It’s also important to wear proper personal protective equipment (PPE) to safeguard yourself and prevent accidental damage to your electronics. Additionally, be mindful of the vibrations and electrical interference generated by power tools and take necessary steps to minimize their impact on nearby electronic devices, such as proper grounding and insulation.

Can low voltage damage electronics?

Summary

Okay, so here’s what we’ve learned about power tools and electronics. First off, power tools can definitely damage your electronics if you’re not careful. The vibrations and electrical interference from the tools can mess up the delicate components inside your devices. So, keep your tools away from your gadgets!

But don’t worry too much. There are ways to protect your electronics. You can use surge protectors, which help to absorb any surges in electricity. Also, be sure to handle your electronics with care and keep them in a safe place. And if you’re using power tools nearby, maybe consider moving your electronics to a different room, just to be on the safe side. Take care of your tools and your gadgets, and everything should be A-OK!