Are you curious to know if router bits can cut aluminum? Well, you’ve come to the right place! In this article, we’ll explore the exciting world of router bits and discover whether they can tackle aluminum like a pro. So, let’s jump right in and find out if these versatile tools can handle this metal marvel!

When it comes to woodworking, router bits are the unsung heroes. From shaping edges to creating intricate designs, these trusty tools have mastered the art of cutting through wood with precision. But what about aluminum? Can router bits handle this tougher material? It’s time to unravel the mystery and see if these bits are up to the challenge!

If you’ve ever wondered whether router bits can conquer aluminum, you’re not alone. Many DIY enthusiasts and woodworkers have pondered this very question. So, let’s roll up our sleeves, put on our safety goggles, and embark on a journey to discover if router bits can cut through aluminum with finesse. Get ready for some fascinating insights!

Can Router Bits Cut Aluminum? Understanding the Possibilities

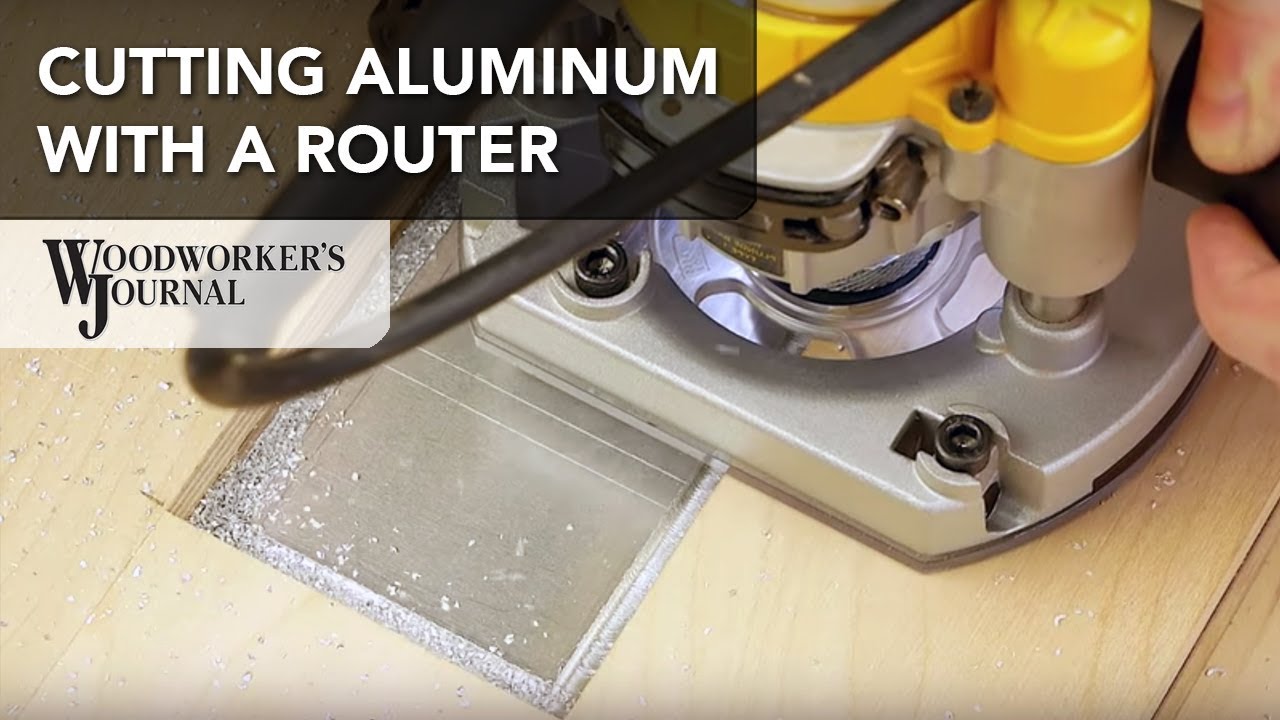

Aluminum is a versatile metal commonly used in various industries, and as a DIY enthusiast or professional woodworker, you may be wondering if router bits can be used to cut aluminum. Router bits are primarily designed for woodworking applications, but with the right precautions and techniques, they can indeed be used to cut aluminum. In this article, we will explore the potential of router bits in cutting aluminum, the necessary considerations, and tips to achieve successful results while ensuring safety.

Understanding Router Bits and Their Limitations

Before diving into the details of cutting aluminum with router bits, it is crucial to understand what router bits are and their limitations. Router bits are small cutting tools that attach to handheld or table-mounted routers. They are primarily used for shaping and cutting various materials, such as wood, plastic, and even some metals. However, it’s important to note that router bits are not specifically designed for cutting metal, especially harder metals like steel. Their cutting edges may dull quickly when used on metals, compromising their effectiveness and potentially leading to damage or breakage.

1. Choosing the Right Router Bit for Aluminum Cutting

When it comes to cutting aluminum with router bits, selecting the right type of bit is crucial. Carbide-tipped router bits are commonly recommended for cutting aluminum due to their hardness and durability. Carbide is a material known for its resistance to wear and ability to maintain sharp cutting edges even when used on harder materials. Opt for carbide-tipped router bits specifically designed for cutting non-ferrous metals like aluminum.

When selecting a router bit for aluminum cutting, consider the following factors:

- Diameter: Choose a bit with a diameter suitable for the size of the aluminum workpiece.

- Flute type: Opt for bits with fewer flutes, such as two or three, as they tend to clear away chips more effectively during the cutting process.

- Coating: Some router bits feature coatings like aluminum titanium nitride (AlTiN) or titanium nitride (TiN) that enhance their durability and reduce friction.

2. Ensuring Safety Measures during Aluminum Cutting

Working with aluminum can pose some safety risks, so it’s crucial to take proper precautions. Here are some essential safety measures to follow when cutting aluminum with router bits:

- Wear safety goggles and a face mask to protect your eyes and respiratory system from metal shavings and dust.

- Use hearing protection, especially when using a router with high RPM to minimize noise exposure.

- Secure the aluminum workpiece firmly to prevent any movement during the cutting process.

- Maintain a clear workspace and remove any potential hazards that could cause accidents.

- Use a dust collection system or work in a well-ventilated area to minimize the inhalation of metal dust.

- Take breaks and rest your hands if the router becomes hot during extended cutting sessions.

3. Techniques and Tips for Successful Aluminum Cutting

While router bits designed for cutting aluminum can handle the task, it is crucial to employ proper techniques to ensure successful results. Here are some tips to help you achieve precise and clean cuts:

- Start with a slower router speed setting to minimize friction and heat buildup.

- Perform test cuts on scrap aluminum pieces before working on the final workpiece to familiarize yourself with the router bit’s performance and optimize your feed rate.

- Take shallow passes to minimize strain on the bit and reduce the chances of chipping or breakage.

- Use cutting lubricants specifically formulated for aluminum to reduce friction and keep the router bit cool.

- Clear away chips regularly during the cutting process to prevent clogging and ensure clean cuts.

- If you encounter any signs of dullness or decreased cutting performance, replace the router bit.

Other Materials Router Bits Can Cut

In addition to aluminum, router bits can be used to cut a wide range of materials, expanding their versatility. Here are some commonly cut materials using router bits:

1. Wood:

Woodworking is the primary application for router bits. Whether you’re shaping edges, creating intricate designs, or making joinery cuts, router bits are indispensable tools for working with wood.

2. Plastic:

Router bits excel at cutting various types of plastics, including acrylic, PVC, and HDPE. They can create clean edges and precise shapes without melting or chipping the material.

3. Laminate:

Router bits are commonly used for trimming laminates, such as those found on countertops, cabinets, and furniture. They can create smooth and precise cuts without damaging the delicate laminate surface.

4. MDF and Particle Board:

Medium-density fiberboard (MDF) and particle board are commonly used in construction and woodworking projects. Router bits can effortlessly cut and shape these materials, allowing for detailed designs and precise cuts.

In Summary

While router bits are primarily designed for woodworking applications, they can indeed be used to cut aluminum with the right bit selection, precautions, and techniques. When working with aluminum, always prioritize safety, choose the appropriate router bit, and ensure proper techniques are employed for successful results. Router bits are versatile tools that can be used to cut various materials, including wood, plastic, laminate, and MDF. With proper care and knowledge, you can achieve precise and clean cuts, expanding the possibilities of your router bit usage.

Key Takeaways: Can Router Bits Cut Aluminum?

- Yes, router bits can cut aluminum, but not all router bits are suitable for this material.

- You need to use carbide bits specifically designed for cutting aluminum.

- High-speed steel or regular router bits may get dull quickly or break when used on aluminum.

- Router bits with solid carbide or carbide-tipped edges are the best choice for cutting aluminum.

- Always use proper safety precautions and techniques when working with router bits and aluminum.

Frequently Asked Questions

Welcome to our FAQ section where we will address some common queries about using router bits to cut aluminum. Whether you’re a hobbyist or a professional, cutting aluminum with a router can save you time and effort. Read on to find answers to your burning questions!

1. Can router bits be used to cut aluminum?

Yes, router bits can be used to cut aluminum, but it’s important to select the right type of bit for the job. It is recommended to use solid carbide bits, as they are specifically designed for cutting metals like aluminum. Carbide bits have sharp edges and are much harder than high-speed steel bits, making them more durable and effective for aluminum cutting. When using router bits to cut aluminum, it’s important to take proper safety precautions, such as wearing protective eyewear and gloves.

Additionally, it’s crucial to consider the speed and feed rate when cutting aluminum. Aluminum requires higher speeds and slower feed rates compared to wood or plastic. This ensures clean cuts and prevents the bit from getting too hot. Always refer to the manufacturer’s guidelines for the specific router bit you are using, as they may have specific recommendations for cutting aluminum.

2. What type of router bit should I use for cutting aluminum?

For cutting aluminum with a router, it is recommended to use solid carbide end mills or compression bits. These types of bits are designed to withstand the high speeds and feed rates required for aluminum cutting. Solid carbide end mills have sharp cutting edges on the sides and bottom, while compression bits have both up-cut and down-cut flutes, allowing for clean cuts on both sides of the material.

When choosing a router bit, consider the diameter and length of the bit, as well as the cutting depth required for your project. It’s always a good idea to have multiple router bits in different sizes and styles to accommodate different cutting needs.

3. What router speed should I use when cutting aluminum?

When cutting aluminum with a router, it’s important to use higher speeds compared to cutting wood or plastic. The exact speed may vary depending on the specific router and bit you are using, but in general, setting the router speed between 18,000 and 24,000 RPM is recommended for cutting aluminum.

However, it’s crucial to refer to the manufacturer’s guidelines for your specific router and bit, as they may have specific recommendations based on their design and materials. It’s also advisable to start with a slower speed and gradually increase it until you achieve the desired cutting performance.

4. How can I ensure clean cuts when cutting aluminum with a router?

To ensure clean cuts when cutting aluminum with a router, there are a few key factors to consider. First, make sure you are using a sharp and properly maintained router bit. Dull or damaged bits can result in poor-quality cuts and can even cause damage to the router or workpiece.

Second, take care to secure the aluminum piece firmly in place to minimize vibrations. This can be done using clamps or a router table with a fence. Minimizing vibrations helps prevent chattering and ensures a smoother cut. Finally, consider using coolant or lubricant specifically designed for cutting aluminum. This can help reduce heat buildup and prolong the life of your router bit.

5. What safety precautions should I take when cutting aluminum with a router?

When cutting aluminum with a router, it is essential to prioritize safety. Always wear protective eyewear to shield your eyes from any debris that may be generated during the cutting process. Additionally, wearing gloves can help protect your hands from sharp edges and metal shavings.

Ensure that you have a stable working surface and secure the material firmly to avoid any unintended movement during the cutting process. Finally, follow the manufacturer’s guidelines for your specific router and bit, as they may have additional safety recommendations or precautions to take into account.

Summary

So, can router bits cut aluminum? The answer is yes! With the right bit and precautions, you can use a router to cut aluminum. However, it’s important to choose a carbide-tipped bit specifically designed for cutting metal. You should also go slow, use lubricant, and wear safety gear like goggles and gloves. Remember, cutting aluminum with a router may create sharp edges, so use caution and handle the material carefully after cutting. With the right tools and precautions, you can successfully cut aluminum with a router!