Can router bits cut aluminum? If you’ve ever wondered about using your router for aluminum projects, you’re in the right place! In this article, we’ll explore the fascinating world of router bits and their capabilities when it comes to cutting aluminum.

But why would you want to use a router for aluminum in the first place? Well, routers are incredibly versatile tools known for their precision and efficiency. They’re commonly used for woodworking, but with the right setup and the right router bits, you can also tackle aluminum projects with ease.

So, whether you’re a DIY enthusiast or a professional looking to expand your skillset, join us as we delve into the exciting possibilities of using router bits to cut aluminum. Let’s dive in and explore the ins and outs of this intriguing topic!

– Secure the aluminum piece

– Install the carbide-tipped bit

– Set the cutting depth

– Adjust the speed

– Make the cut in multiple passes

Remember to always wear safety goggles and gloves when working with power tools.

Can Router Bits Cut Aluminum?: A Comprehensive Guide

Aluminum is a versatile and lightweight material that is widely used in various industries. One common question that arises is whether router bits can be used to cut aluminum. In this article, we will explore the feasibility of using router bits for aluminum cutting, the challenges involved, and essential tips to ensure success.

The Feasibility of Using Router Bits for Aluminum Cutting

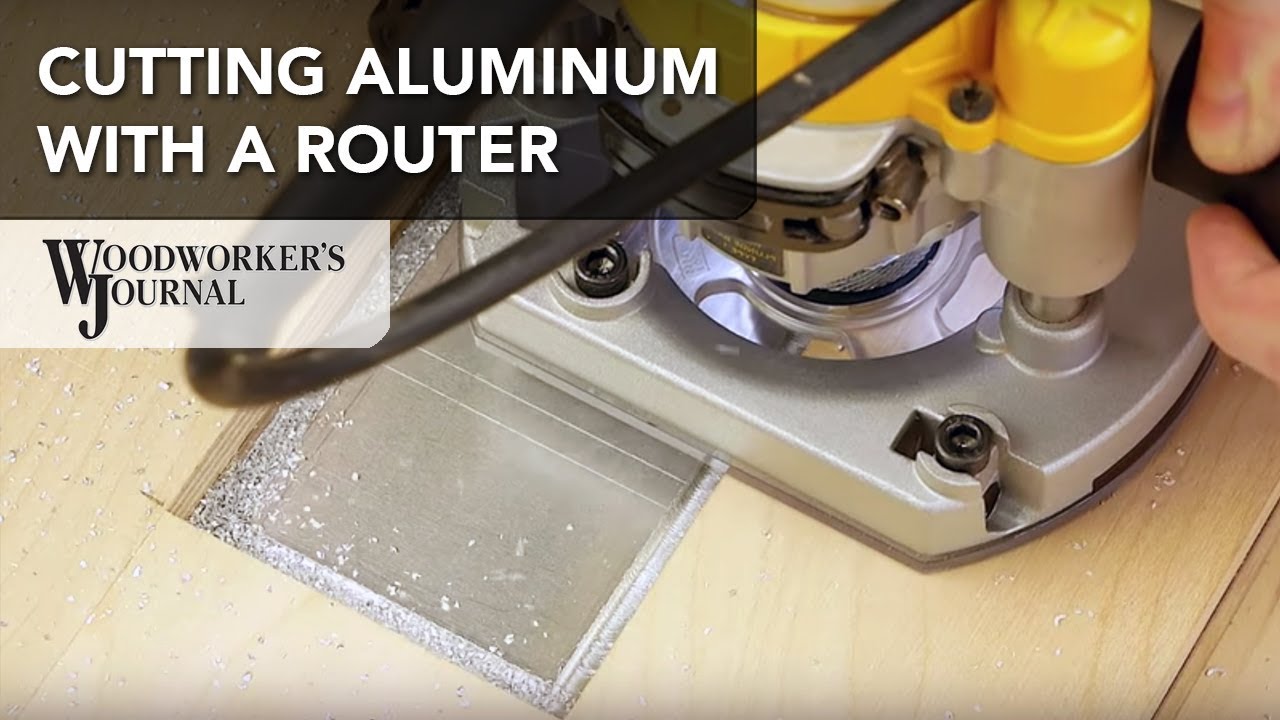

Router bits are primarily designed for woodworking applications, such as cutting, shaping, and carving wooden materials. However, with the right setup and precautions, they can also be used to cut aluminum. It is important to note that not all router bits are suitable for aluminum cutting. Specialized router bits with carbide or diamond tips are recommended for this purpose.

One of the main challenges of cutting aluminum with router bits is the high speed of rotation. Aluminum is a soft metal, and the high RPM (revolutions per minute) of the router can cause the material to heat up and melt rather than being neatly cut. To overcome this, it is crucial to use a lower cutting speed, lubricate the material, and ensure proper chip evacuation to prevent heat buildup.

Additionally, the router should be equipped with a sturdy base plate and a strong motor to handle the increased pressure and load during aluminum cutting. It is also important to secure the workpiece properly and use appropriate safety gear, including goggles, gloves, and a dust mask, as aluminum chips and dust can be hazardous.

The Importance of Choosing the Right Router Bits

When it comes to cutting aluminum with router bits, selecting the right type of bits is crucial for achieving clean and accurate cuts. Carbide-tipped or diamond-tipped bits are the most suitable options for aluminum cutting. These bits are specifically designed to withstand the high speed and heat generated during the cutting process. They have sharper and more robust cutting edges compared to standard bits, ensuring cleaner cuts and longer tool life.

Furthermore, it is recommended to choose bits with a high helix angle. A higher helix angle helps in efficient chip evacuation, reducing the risk of heat buildup. It is also advisable to opt for bits with a low rake angle, as this minimizes the cutting forces and subsequent heat generation. These specialized bits are readily available in the market, and investing in high-quality router bits will significantly enhance your aluminum cutting capabilities.

It is important to note that when using router bits for aluminum cutting, they may wear out faster compared to woodworking applications. Continuous monitoring of the bit’s condition and regular sharpening or replacement will ensure optimal performance and precise cuts.

Tips for Successful Aluminum Cutting with Router Bits

As mentioned earlier, cutting aluminum with router bits requires specific techniques and precautions to achieve desirable results. Here are some essential tips to follow:

- Use a lower cutting speed: Aluminum cutting requires slower feed rates and RPM to prevent melting and improve accuracy.

- Lubricate the material: Applying a cutting lubricant or a coolant will help reduce friction and heat buildup during the cutting process.

- Use a suitable router setup: Ensure that your router is equipped with a sturdy base plate and a powerful motor to handle the demands of aluminum cutting.

- Secure the workpiece: Properly clamp or hold down the workpiece to prevent movement or vibrations, which can affect the accuracy of the cuts.

- Implement effective chip evacuation: Aluminum chips can accumulate quickly, leading to poor cutting performance. Use a vacuum or compressed air to remove chips and prevent clogging.

- Wear appropriate safety gear: Protect yourself from flying chips and dust by wearing safety goggles, gloves, and a dust mask.

- Monitor bit condition: Regularly inspect the router bit for signs of wear and sharpen or replace as needed to maintain optimal performance.

Benefits of Using Router Bits for Aluminum Cutting

While using specialized router bits for aluminum cutting may require additional considerations, it offers several benefits:

- Versatility: With the right bits, your existing woodworking router can be used for cutting aluminum, expanding its capabilities without the need for purchasing dedicated machinery.

- Cost-effective: Investing in high-quality router bits is more economical compared to buying specialized aluminum cutting tools.

- Accuracy: Router bits provide the precision and control required for intricate cuts and shaping in aluminum projects.

- Wide range of profiles: Router bits come in various profiles and shapes, allowing for decorative or functional designs in aluminum projects.

- Ease of use: If you are already familiar with using a router for woodworking, adapting to cutting aluminum will require minimal additional training or learning.

Common Misconceptions about Using Router Bits for Aluminum Cutting

Although using router bits for aluminum cutting is possible with the right techniques and tools, there are some common misconceptions that need to be addressed.

Myth: Standard router bits can effectively cut aluminum

Fact: Standard router bits are not designed for cutting aluminum and may wear out quickly or produce unsatisfactory cuts. Specialized bits with carbide or diamond tips are required for optimal results.

Myth: Aluminum cutting with router bits is unsafe

Fact: While caution is necessary when cutting aluminum, taking proper safety precautions, such as wearing appropriate gear and securing the workpiece, ensures a safe cutting experience.

Myth: Router bits for aluminum cutting are expensive

Fact: Although high-quality router bits suitable for aluminum cutting may be slightly more expensive than standard woodworking bits, they are a cost-effective solution compared to purchasing specialized machinery.

Conclusion

Router bits can be used to cut aluminum with the proper techniques, tools, and precautions in place. By using specialized bits and following essential tips, you can achieve precise and clean cuts in aluminum projects. Remember to choose the right router bits, properly set up your router, and take necessary safety measures to ensure a successful aluminum cutting experience. With the versatility and accuracy offered by router bits, you can expand your creative possibilities in working with aluminum and achieve professional results.

Can Router Bits Cut Aluminum? – Key Takeaways

- Router bits can cut aluminum, but they need to be specifically designed for metal cutting.

- Using the wrong type of router bit on aluminum can result in poor performance and damage to the bit.

- Carbide or diamond-tipped router bits are recommended for cutting aluminum.

- It is important to use proper cutting techniques and lubrication when working with aluminum.

- Always wear appropriate safety gear, such as goggles and gloves, when using router bits on aluminum.

Router bits can be used to cut aluminum, but it’s crucial to use the right type of bit. Carbide or diamond-tipped bits are recommended for cutting aluminum as they are more durable and can withstand the hardness of the metal. However, it’s important to follow proper cutting techniques and use appropriate lubrication to ensure smooth and accurate cuts. Additionally, always prioritize safety by wearing protective gear when working with router bits on aluminum.

Frequently Asked Questions

Here are some common questions related to using router bits to cut aluminum, along with their answers:

1. What are router bits and can they be used to cut aluminum?

Router bits are cutting tools specifically designed for routers, used to create various shapes and profiles in different materials. While router bits are primarily used for woodworking, some types of router bits can also cut aluminum. However, it’s important to choose the right type of router bit and use the appropriate cutting techniques to ensure successful results.

When it comes to cutting aluminum with router bits, it’s recommended to use bits specifically designed for metalworking. These bits typically have a high-speed steel (HSS) or carbide cutting edge, which can withstand the hardness of aluminum. Additionally, using a lubricant like cutting oil can help in reducing heat buildup during the cutting process.

2. What types of router bits are suitable for cutting aluminum?

There are a few types of router bits that work well for cutting aluminum:

– Straight Bits: Straight bits with HSS or carbide cutting edges can be used to make simple cuts in aluminum sheets or plates.

– Spiral Bits: Spiral bits, also known as up-cut and down-cut bits, are designed to remove material efficiently. These bits work well for cutting aluminum, as they prevent chip clogging and provide smoother cutting.

– Compression Bits: Compression bits have both an up-cut and a down-cut flute. They are ideal for cutting aluminum laminates or composite materials, as they minimize the risk of delamination during the cutting process.

It’s crucial to choose the right type of router bit for the specific aluminum cutting task to ensure clean and accurate results.

3. What safety precautions should I take when cutting aluminum with router bits?

When working with router bits to cut aluminum, it’s essential to prioritize safety. Here are some precautions to follow:

– Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection.

– Securely clamp the aluminum workpiece to prevent movement during the cutting process.

– Start with a lower speed setting on your router to minimize the risk of bit breakage or chatter.

– Use proper cutting techniques, such as making multiple shallow passes instead of trying to remove too much material at once.

– Regularly inspect and maintain your router bits to ensure they are in good condition and sharp.

By following these safety precautions, you can minimize the risk of accidents and achieve successful results when cutting aluminum with router bits.

4. Can I use regular woodworking router bits to cut aluminum?

While it’s technically possible to use regular woodworking router bits to cut aluminum, it is not recommended. Woodworking router bits are generally not designed to withstand the hardness of metal, and using them on aluminum can lead to excessive wear, poor cutting performance, and potentially damaging the bits.

If you need to cut aluminum frequently, it’s best to invest in router bits specifically designed for metalworking. These specialized bits are made with materials and cutting edge geometries that can handle the demands of cutting aluminum, ensuring better results and longer tool life.

5. What are some tips for achieving clean cuts when using router bits to cut aluminum?

To achieve clean cuts when using router bits to cut aluminum, consider the following tips:

– Choose the appropriate feed speed when operating your router. A slower feed speed can help prevent excessive heat buildup, resulting in smoother cuts.

– Use cutting oil or lubricant on the aluminum surface to cool down the router bit and reduce friction.

– Take multiple shallow passes instead of trying to remove too much material at once. This approach helps prevent chip clogging and produces cleaner cuts.

– Securely hold or clamp the workpiece to prevent vibration, which can lead to rough cuts.

– Regularly inspect the router bit for any signs of wear or dullness. A sharp bit is crucial for achieving clean and precise cuts.

By following these tips, you can enhance your cutting results and achieve cleaner cuts when using router bits to cut aluminum.

Summary

So, can router bits cut aluminum? The answer is yes, but with some limitations and precautions. Router bits designed specifically for aluminum can effectively cut through this metal, but using standard router bits meant for wood can cause damage. It’s crucial to choose the right type of bit and to adjust the speed and feed rate appropriately to ensure a successful aluminum cutting experience.

In conclusion, if you have the right tools and take the necessary safety measures, router bits can be used to cut aluminum. However, it’s essential to be mindful of the limitations and risks involved in this process. Always prioritize safety and follow the manufacturer’s guidelines to achieve the best results.