Can you chisel particle board? If you’ve ever wondered about this, you’re in the right place! Today, we’re diving into the world of woodworking to explore whether or not chiseling particle board is a good idea. So, grab your tools and let’s find out!

When it comes to woodworking projects, particle board is a popular material due to its affordability and versatility. But can you really use a chisel on it? Well, the answer might surprise you. Chiseling particle board can be a bit challenging because it’s not as strong as solid wood. However, with the right techniques and tools, you can still achieve satisfactory results.

In this guide, we’ll walk you through the process of chiseling particle board, including the tools you’ll need, tips for success, and alternative methods. So, whether you’re a beginner woodworker or an experienced DIY enthusiast, get ready to learn how to work with particle board in a whole new way!

The Definitive Guide: Can You Chisel Particle Board?

In the world of woodworking, particle board is a commonly used material due to its affordability and versatility. However, one question that often arises is whether or not it is possible to chisel particle board. In this comprehensive guide, we will explore the ins and outs of chiseling particle board, providing you with the information you need to know before you grab your tools and get to work.

Understanding Particle Board

Particle board is composed of wood chips, shavings, and sawdust that are bound together using a resin or glue. It is an engineered wood product that is known for its durability and stability. Particle board is often used in the construction of furniture, cabinets, and shelving due to its affordability and ability to be easily cut and shaped. However, due to its composition, particle board can present some challenges when it comes to chiseling.

When attempting to chisel particle board, it is important to keep in mind that it is a much softer material compared to solid wood. The wood fibers within particle board are not as tightly packed, which means that it is more prone to chipping and splintering. Additionally, particle board does not have the same structural integrity as solid wood, making it more susceptible to damage when subjected to the pressure of a chisel.

The Challenges of Chiseling Particle Board

Chiseling particle board can be a delicate process due to its composition and the potential for damage. Here are some of the main challenges you may encounter:

1. Splintering: Particle board is prone to splintering, especially along the edges or when being chiseled against the grain. This can result in uneven and unsightly chisel marks.

2. Chipping: Due to the softness of particle board, it is easy for the chisel to dig too deep and chip away chunks of the material. This can compromise the integrity of the piece being worked on.

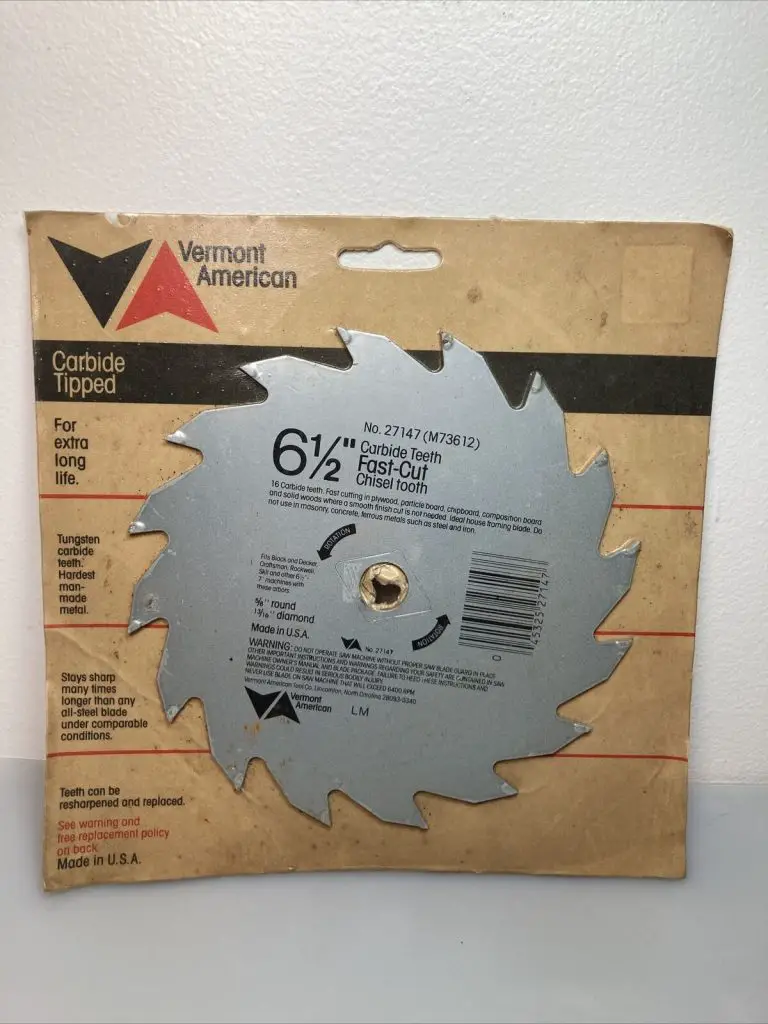

3. Blunting of Tools: The abrasive nature of the resin or glue used to bind particle board can quickly dull the sharp edge of your chisel. This means you may need to sharpen your tools more frequently when working with particle board.

Tips for Chiseling Particle Board

While chiseling particle board can be challenging, with the right techniques and precautions, it is possible to achieve clean and precise results. Here are some tips to help you navigate the process:

1. Choose the Right Tools: Opt for a sharp chisel with a beveled edge to reduce the chances of splintering. It is also recommended to use a smaller size chisel for more control and precision.

2. Mark Your Cuts: Before chiseling, it is important to mark your cuts using a pencil or masking tape. This will help prevent the wood from splintering or chipping during the process.

3. Take It Slow: Particle board requires patience and a gentle approach. Take your time and make shallow cuts, gradually increasing the depth as you go. This will help minimize the risk of splintering or chipping.

4. Support the Workpiece: To prevent excessive chipping, it is helpful to support the particle board with a sacrificial piece of wood or clamp it down securely before chiseling.

5. Test on Scrap Material: If you are new to chiseling particle board, it is advisable to practice on a scrap piece of the same material before working on your actual project. This will allow you to get a feel for the material and perfect your technique.

In conclusion, chiseling particle board is indeed possible, though it comes with its challenges. By understanding the nature of particle board, being aware of the potential issues, and employing the right techniques, you can achieve clean and precise chisel work. Remember to take your time, use sharp tools, and practice on scrap material before tackling your main project. With care and patience, you can create beautiful and detailed designs on particle board.

Key Takeaways: Can You Chisel Particle Board?

- Chiseling particle board is possible but it may not give you the best results.

- Particle board is made from wood particles and other materials that are pressed together.

- Chiseling can cause the particle board to chip or splinter due to its composition.

- It is recommended to use a different material like solid wood or plywood for chiseling projects.

- If you must chisel particle board, use sharp and precise tools to minimize damage.

Frequently Asked Questions

Welcome to our FAQ section where we address common questions regarding chiseling particle board. Whether you’re a DIY enthusiast or just curious, we’ve got you covered with informative answers. Read on to find out more!

Can you use a chisel on particle board?

Absolutely! Particle board can be chiseled, but it does require some caution and care. Since particle board is made up of compressed wood particles and resin, it’s not as dense or durable as solid wood. When chiseling particle board, it’s crucial to use a sharp chisel and work slowly, allowing the blade to cut through the material effectively without damaging it. Additionally, it’s important to support the board properly to prevent splintering or breaking.

Before you start chiseling, mark the area you want to remove with a pencil. Then, using a sharp chisel, make light score marks along the marked line to create a trench. Gradually deepen the trench with precise chisel strokes until you reach the desired depth. Take your time, be patient, and always work with caution to achieve clean and accurate results.

What type of chisel is best for cutting particle board?

When it comes to cutting particle board, a sharp bench chisel or a wood chisel with a beveled edge is a suitable choice. A bench chisel provides a good balance between strength and precision, enabling you to make controlled cuts. Look for a chisel with a blade width that suits your project’s requirements, ensuring it is between 1/4 to 1 inch wide for optimal performance on particle board.

Also, consider the chisel’s handle. Comfortable grip and control are essential, especially when working on detailed cuts. It’s recommended to choose a chisel with an ergonomic handle that suits your hand size and offers a secure grip. Remember, a sharp tool is crucial for cutting particle board effectively, so make sure to sharpen your chisel before each use.

Can I use a power chisel on particle board?

Using a power chisel on particle board can yield mixed results. While it may be possible to use a power chisel, keep in mind that particle board is not as sturdy as solid wood, so there is a higher risk of splintering or damaging the material. It’s important to be cautious and choose a low speed setting on your power chisel to minimize these risks.

If you decide to use a power chisel on particle board, make sure the tool is properly adjusted and secured. Use light, controlled pressure, and proceed slowly to allow the blade to cut through the material without causing excessive vibrations or tear-outs. Remember to always wear safety goggles and other appropriate safety gear to protect yourself while using power tools.

How do I prevent chipping when chiseling particle board?

To prevent chipping when chiseling particle board, there are a few techniques you can employ. First, ensure that you are using a sharp chisel. A dull blade is more likely to cause splintering and chipping. Regularly sharpen and maintain your chisel, and consider using a honing guide for precise sharpening.

Additionally, supporting the particle board properly is crucial. Place a sacrificial backing board behind the piece you are chiseling to provide support and minimize tear-outs. Take your time and work with gentle, controlled strokes, allowing the chisel to cut through the material without applying excessive force. This will help prevent chipping and produce cleaner results. Lastly, consider practicing on a scrap piece of particle board before working on your actual project to gain confidence and refine your technique.

Are there any alternative methods to chiseling particle board?

Absolutely! If you’re concerned about chiseling particle board or looking for alternative methods, there are a few options that may suit your needs. One option is to use a router with an appropriate bit to shape or cut the particle board. Routers are versatile tools that offer greater precision and control compared to chisels. Just make sure to secure the particle board properly before routing to prevent any movement or damage.

Another method is using a jigsaw fitted with a fine-toothed blade. A jigsaw allows you to make curved or intricate cuts in particle board with ease. It’s ideal for cutting shapes or creating openings. Remember to mark the area you want to cut accurately and keep a steady hand while guiding the jigsaw to ensure clean and accurate cuts. Whichever method you choose, always prioritize safety and use the necessary safety equipment for the specific tool you are utilizing.

The Truth About PARTICLE BOARD…Is It The Worst Material?! (Pros + Cons…Particle Board)

Summary

Chiseling particle board is not a good idea because it is made of wood chips and glue, making it prone to splintering and damage. It is better to use tools like a saw to cut or shape particle board. Safety goggles and a face mask are recommended when working with particle board to avoid inhaling harmful dust particles.

If you still want to chisel particle board, start by making a shallow cut with a utility knife, then use a chisel with a honed edge to carefully remove the material. Take your time to avoid any accidents and make sure to use a sharp chisel for better control. Remember to always work in a well-ventilated area to minimize exposure to dust and fumes.