Can you cut aluminum with a circular saw? If you’ve ever wondered about this, you’ve come to the right place! In this article, we’ll explore the possibilities of using a circular saw to cut through aluminum. So, put on your safety goggles and let’s dive in!

Now, you might be thinking, “Why would I even want to cut aluminum with a circular saw?” Well, the answer is simple. Aluminum is a versatile metal used in various industries, from construction to DIY projects. Being able to cut it efficiently and accurately can open up a world of possibilities for you!

But here’s the thing: cutting aluminum with a circular saw requires some know-how. It’s not as straightforward as cutting through wood or other materials. So, in the next few paragraphs, we’ll discuss the factors to consider, the tools you’ll need, and some tips and tricks to ensure a successful aluminum cutting adventure!

So, if you’re ready to learn the ins and outs of cutting aluminum with a circular saw, let’s get started!

Can You Cut Aluminum with a Circular Saw?

Have you ever wondered if it is possible to cut aluminum with a circular saw? In this article, we will explore the answer to this question in detail. We will provide you with all the information you need to know about cutting aluminum with a circular saw, including the tools and techniques required and any potential challenges you may face. So, let’s dive in and discover if you can indeed cut aluminum with a circular saw!

Why You Might Want to Cut Aluminum with a Circular Saw

Before we delve into the details of cutting aluminum with a circular saw, let’s first understand why you might want to do so. Aluminum is a versatile material used in various applications ranging from construction and automotive industries to DIY projects. Being able to cut aluminum with a circular saw can offer convenience and save time, allowing you to work with this lightweight and durable material more efficiently. Now, let’s explore the process of cutting aluminum with a circular saw.

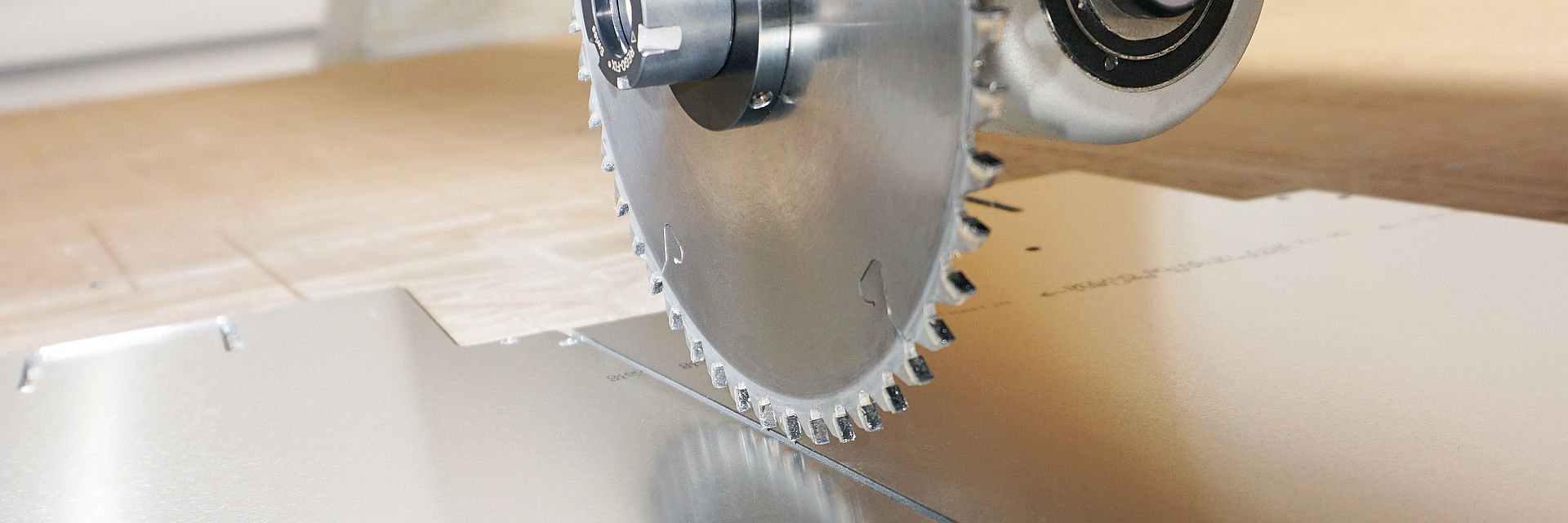

Choosing the Right Blade

The first step in cutting aluminum with a circular saw is selecting the right blade. Not all blades are suitable for cutting through aluminum. You will need to choose a blade specifically designed for non-ferrous metals like aluminum. These blades usually have a high tooth count and are made of carbide or tungsten carbide-tipped material. The high tooth count allows for smoother and cleaner cuts, while the durability of the carbide or tungsten carbide-tipped material ensures longevity and precision in cutting aluminum.

When selecting a blade, consider the thickness of the aluminum you will be cutting. Thicker aluminum may require a blade with a larger diameter to ensure efficient cutting. Check the manufacturer’s recommendations to ensure you have the right blade size and type for your specific cutting needs.

Additionally, it is crucial to inspect the blade for any signs of damage or dullness before use. A dull blade can cause rough cuts and increase the risk of accidents. If you notice any issues with the blade, replace it before proceeding with your aluminum cutting project.

Preparing the Aluminum for Cutting

Once you have the appropriate blade, the next step is to prepare the aluminum for cutting. Start by measuring and marking the area you need to cut. Use a straightedge or a square to ensure accurate markings. This step is crucial for achieving precision in your cuts and avoiding any unnecessary mistakes.

After marking the area, secure the aluminum piece firmly in place. You can use clamps or vices to hold it securely. The stability of the aluminum is essential to prevent vibrations or movement during the cutting process, which can affect the quality of the cuts.

Lastly, consider using a lubricant or cutting compound to improve the cutting process. Aluminum has a tendency to stick to saw blades, which can result in rough cuts. Applying a lubricant or cutting compound can reduce friction and ensure smoother cuts.

The Cutting Process

Now that you have the correct blade and have prepared the aluminum, it’s time to begin the cutting process. Follow these steps:

- Put on appropriate safety gear, including safety goggles and ear protection.

- Position the circular saw on the marked cutting line, ensuring the blade is aligned with the markings.

- Start the circular saw and allow the blade to reach full speed.

- Gently push the saw forward, allowing the blade to cut through the aluminum. Take your time and avoid applying excessive force, as this can cause unnecessary bending or damage to the material.

- Continue cutting along the marked line until the desired length or shape is achieved.

- Once the cut is complete, turn off the saw and allow the blade to come to a complete stop before removing it from the aluminum piece.

- Inspect the cut to ensure it meets your requirements. If necessary, use a file or sandpaper to smooth any rough edges or burrs.

Benefits of Cutting Aluminum with a Circular Saw

Now that you know the process of cutting aluminum with a circular saw, let’s explore some of the benefits it offers:

- Efficiency: Using a circular saw allows for quick and precise cuts, saving time and effort.

- Versatility: Circular saws are versatile tools that can be used for various cutting tasks, including aluminum.

- Cost-effective: Circular saws are relatively affordable compared to other specialized tools.

- DIY-friendly: Cutting aluminum with a circular saw is a feasible option for DIY enthusiasts who want to work with this material.

Additional Considerations for Cutting Aluminum with a Circular Saw

While cutting aluminum with a circular saw is possible, there are a few additional considerations to keep in mind:

Ensuring Safety

Always prioritize safety when working with power tools, including circular saws. Wear appropriate safety gear, such as goggles and ear protection, and follow the manufacturer’s instructions for safe operation. Additionally, be cautious of flying debris and use clamps or vices to secure the aluminum piece firmly in place. This will minimize the risk of accidents and ensure a safe cutting process.

Minimizing Heat Build-up

When cutting aluminum, heat can be generated due to the friction between the blade and the material. To prevent excessive heat build-up, consider using a cutting lubricant or compound to reduce friction and prolong the life of your blade. Additionally, take breaks during extended cutting sessions to allow the blade to cool down and prevent overheating.

Choosing the Right Saw

While circular saws are capable of cutting through aluminum, not all saws are created equal. If you plan to work extensively with aluminum, consider investing in a higher-quality circular saw specifically designed for metal cutting. These saws often feature enhanced motor power and specialized blades, providing better performance and longevity when cutting aluminum.

Key Takeaways – Can You Cut Aluminum With a Circular Saw?

- Yes, you can cut aluminum with a circular saw.

- Ensure that you use the right blade for cutting aluminum.

- Choose a blade with carbide-tipped teeth for clean and efficient cuts.

- Use a lubricant like cutting oil or wax to reduce heat and extend blade life.

- Wear appropriate safety gear like safety glasses and gloves when cutting aluminum.

Frequently Asked Questions

Are you wondering if a circular saw can be used to cut aluminum? Look no further! Here are answers to some common questions on this topic.

Can a circular saw cut through aluminum?

Yes, a circular saw can indeed cut through aluminum with the right blade. However, it is important to use a blade specifically designed for cutting non-ferrous metals like aluminum. These blades typically have carbide teeth or diamond tips that can handle the material without overheating or getting damaged.

When using a circular saw to cut aluminum, make sure to set the saw’s speed to a lower setting if possible, as cutting at high speeds can cause excessive heat and result in blade damage or a rough cut. Additionally, it’s a good idea to secure the aluminum firmly and use clamps or a vise to prevent any movement during the cutting process.

What type of blade should I use to cut aluminum with a circular saw?

It is important to use a blade specifically designed for cutting non-ferrous metals when cutting aluminum with a circular saw. Look for blades with carbide teeth or diamond tips, as they are specifically engineered to handle the unique challenges of cutting aluminum.

Make sure to choose a blade with a higher tooth count, such as 60 to 80 teeth per inch, as this will help ensure a smoother and cleaner cut on the aluminum. Avoid using blades meant for cutting wood or other materials, as they are not designed to effectively cut through aluminum and may result in a rough or uneven cut.

What safety precautions should I take when cutting aluminum with a circular saw?

When cutting aluminum with a circular saw, it is important to prioritize safety. Always wear appropriate safety gear, including safety glasses to protect your eyes from any flying debris, and gloves to protect your hands from sharp edges.

Ensure that the aluminum is securely clamped down and stable before starting the cut. This will prevent any unexpected movement or shifting during the cutting process. Also, be mindful of the saw’s position and keep your hands and body clear of the cutting path to avoid accidents. Lastly, take breaks if needed to prevent the saw from overheating and to ensure your own safety.

What are some tips for achieving a clean cut when cutting aluminum?

To achieve a clean cut when cutting aluminum with a circular saw, there are a few tips you can follow. First, make sure you have the right blade for the job – a blade designed for non-ferrous metals like aluminum.

Ensure that the blade is sharp and in good condition, as a dull blade can result in a rough cut. Set the saw’s speed to a lower setting, if possible, to reduce the risk of overheating and to maintain better control of the cut. Using cutting lubricant or a spray with a silicone base can also help reduce friction and produce a cleaner cut.

Can I use a regular wood-cutting blade to cut aluminum with a circular saw?

Using a regular wood-cutting blade to cut aluminum with a circular saw is not recommended. Wood-cutting blades are designed for cutting through wood fibers, and they may not be able to effectively cut through the harder and denser aluminum material.

Using a wood-cutting blade on aluminum can result in a rough and uneven cut, as well as potentially damage the blade. It is best to use a blade specifically designed for cutting non-ferrous metals like aluminum to achieve the cleanest and most precise cuts.

Summary

Cutting aluminum with a circular saw is possible, but it requires the right blade. Aluminum-cutting blades have fewer teeth and are made of carbide, which is tougher than regular steel blades. It’s important to wear protective gear and use a slow cutting speed to avoid overheating the blade. Lastly, aluminum chips can be sharp, so be careful and clean up properly.

If you’re a 13-year-old and want to cut aluminum with a circular saw, remember these key points. Get an aluminum-cutting blade, wear safety gear, cut slowly, and clean up carefully. With the right precautions, you can safely use a circular saw to cut aluminum.