Can you cut foam board with a table saw? If you’ve ever wondered about this, you’re in the right place. Table saws are incredibly versatile tools, but when it comes to cutting foam board, there are a few things you need to know.

First off, let’s address the main question: can you cut foam board with a table saw? The short answer is yes! A table saw can be a great option for cutting foam board, thanks to its powerful motor and precise cutting ability.

But before you grab your table saw and start cutting away, there are some important factors to consider. In the following sections, we’ll discuss the proper techniques, safety precautions, and tips to ensure clean and accurate cuts when using a table saw for foam board. So, let’s dive in and get cutting!

Wondering if it’s possible to cut foam board with a table saw? While it’s technically possible, it’s not recommended due to the risk of the foam board tearing or melting. A better option is to use a foam cutter or a utility knife with a straight edge. These tools provide better control and precision, ensuring a clean cut. Remember to always prioritize safety and wear appropriate protective gear when working with any power tools.

Can You Cut Foam Board with a Table Saw?

Foam board is a versatile material often used in arts and crafts, as well as building projects. One common question people have is whether it can be cut using a table saw. In this article, we will explore the possibility of cutting foam board with a table saw and provide you with all the information you need to know.

Benefits of Cutting Foam Board with a Table Saw

When it comes to cutting foam board, using a table saw can offer several benefits. Firstly, a table saw provides more stability and control, allowing for straight and accurate cuts. This is especially important when working on precision projects that require clean edges.

Secondly, a table saw is capable of making bevel cuts, which can be useful for creating angled edges or chamfers on foam board. This adds versatility to your projects and enhances the overall finish.

Lastly, using a table saw allows for efficient and time-saving cutting. The blade of a table saw can easily slice through foam board, making the process faster compared to using other tools such as a utility knife or hand saw.

Precautions When Cutting Foam Board with a Table Saw

While cutting foam board with a table saw can be advantageous, there are a few precautions to keep in mind. Firstly, it is important to use the correct blade. A blade with fine teeth, such as a plywood or melamine blade, is recommended for cutting foam board. This will ensure clean cuts and minimize the risk of tearing or damaging the foam.

Additionally, it is crucial to adjust the table saw settings properly. Set the blade height just slightly higher than the foam board to prevent excessive tear-out. Adjust the fence to ensure the board is guided accurately during the cut. Always wear safety goggles and gloves to protect yourself from any potential debris.

Lastly, it is advisable to practice on scrap foam board before working on your actual project. This will allow you to familiarize yourself with the cutting technique and make any necessary adjustments to achieve the desired results.

Tips for Cutting Foam Board with a Table Saw

To ensure successful cutting of foam board with a table saw, here are a few helpful tips:

- Secure the foam board firmly in place using clamps or a sturdy work surface to prevent any movement during the cut.

- Feed the foam board through the table saw slowly and steadily to maintain control and precision.

- Consider using a zero-clearance insert or backing board to minimize tear-out and improve the overall quality of the cut.

- If you need to make a curved or irregular cut on the foam board, it is best to use a different cutting tool, such as a coping saw or a hot wire cutter, which are designed for such tasks.

- Regularly clean the table saw blade to remove any accumulated residue from the foam board. This will ensure smoother cuts and prolong the life of the blade.

Can a Table Saw Cut Different Types of Foam Board?

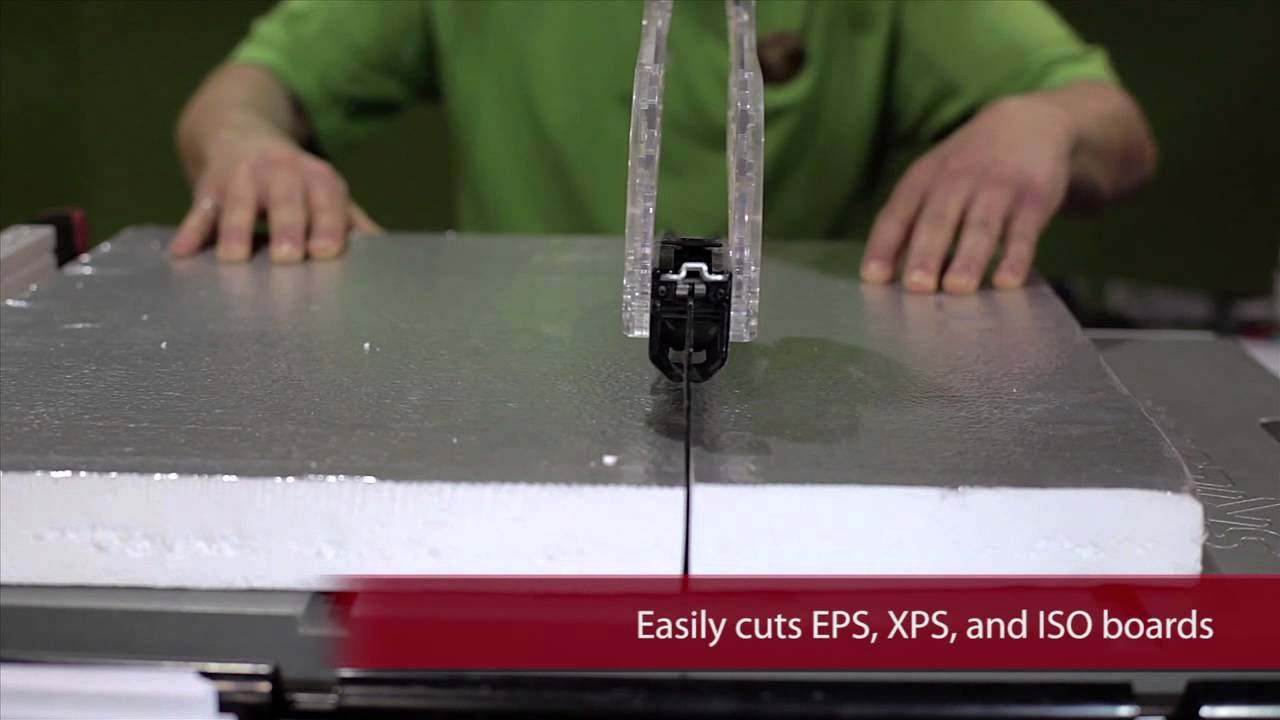

Yes, a table saw can cut through various types of foam board, including expanded polystyrene (EPS) foam, extruded polystyrene (XPS) foam, and polyisocyanurate (polyiso) foam. However, it is essential to choose the appropriate blade for each type to achieve the best results.

For EPS foam, which is the most common type used in crafts and construction, a fine-tooth plywood or melamine blade works well. XPS foam, often found in insulation panels, can be cut using a blade with larger gullets and fewer teeth, such as a blade for cutting plastic or aluminum. Polyiso foam requires a blade with carbide teeth designed for cutting rigid foam insulation.

Always refer to the manufacturer’s recommendations and guidelines when cutting foam board to ensure optimal cutting performance and safety.

Conclusion

So, can you cut foam board with a table saw? The answer is yes, you can! Using a table saw offers stability, accuracy, and the ability to make bevel cuts. However, it is essential to follow safety precautions, use the appropriate blade, and practice on scrap foam board before working on your project. With the right technique and tools, you can achieve clean and precise cuts on different types of foam board.

Can You Cut Foam Board with a Table Saw? Key Takeaways

- Yes, you can cut foam board with a table saw.

- Make sure to use a fine-toothed blade specifically designed for cutting foam.

- Set the blade height to just above the thickness of the foam board.

- Keep the foam board firmly secured on the table saw before cutting.

- Always wear safety goggles and a mask to protect yourself from foam debris.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we address common inquiries about cutting foam boards with a table saw. Whether you’re a DIY enthusiast or a professional carpenter, we’ve got you covered. Read on to find answers to your burning questions!

Can a table saw be used to cut foam boards?

Absolutely! A table saw can be a great tool for cutting foam boards. However, it’s important to take some precautions to ensure a smooth and safe cutting process. Firstly, make sure to use a blade specifically designed for cutting foam, such as a fine-toothed blade. This will prevent the foam from tearing or chipping during cutting. Additionally, it’s recommended to set the table saw to a low speed to minimize vibrations and ensure cleaner cuts. Always remember to wear appropriate safety gear, like safety goggles and gloves, when working with any power tool.

Cutting foam boards with a table saw can be a quick and efficient method, providing precise and clean cuts. With the right set up and precautions, your table saw can become a valuable tool for your foam board cutting needs.

What blade should I use for cutting foam boards?

When cutting foam boards with a table saw, it’s crucial to use the right blade to achieve clean and accurate cuts. The ideal blade for this purpose is a fine-toothed blade specifically designed for cutting foam. These blades have smaller, closely spaced teeth that minimize tear-outs and provide smoother cuts. Avoid using standard woodworking blades, as they are designed for cutting denser materials and may result in rough edges and tear-outs on foam boards.

It’s worth investing in a quality foam cutting blade as it will make a significant difference in the quality of your cuts. Remember to always choose a blade with the right size and teeth configuration for your table saw, as not all blades are compatible with every saw.

How should I prepare the foam board before cutting it?

Before cutting a foam board with a table saw, there are a few steps you can take to ensure optimal results. First, measure and mark the cutting line on the foam board using a straightedge or ruler. This will help you achieve accurate cuts. Next, secure the foam board firmly in place with clamps or a non-slip mat to prevent it from shifting during cutting. If possible, consider using a foam board support system that allows the board to be fully supported throughout the cutting process. This will help maintain stability and minimize vibrations.

Finally, it’s a good idea to make a test cut on a scrap piece of foam board before cutting your actual piece. This will allow you to check the blade’s performance and make any necessary adjustments to ensure precise cuts on your final piece.

What are some tips for achieving clean cuts on foam boards?

To achieve clean cuts on foam boards when using a table saw, there are a few tips you should keep in mind. First, set the blade height so that it protrudes just slightly above the foam board’s thickness. This will help minimize tear-outs and create smoother cuts. Additionally, make sure to feed the foam board through the blade slowly and steadily, avoiding any sudden movements or pushing too hard. Allow the blade to do the work, and guide the foam board steadily along the intended cutting line.

It can also be helpful to attach a sacrificial board to the table saw’s fence. This will help support the foam board and prevent tear-outs as it passes through the blade. Lastly, keep the saw’s table clean and free from debris to ensure greater accuracy and prevent any obstructions during cutting.

What are the safety precautions I should take when cutting foam boards with a table saw?

When working with a table saw, safety should always be a top priority. Here are some essential safety precautions to follow when cutting foam boards:

1. Wear safety goggles, gloves, and hearing protection to protect yourself from flying debris and excessive noise.

2. Ensure the table saw is properly set up, the blade is securely tightened, and the saw is functioning correctly.

3. Familiarize yourself with the table saw’s controls and safety features before using it.

4. Keep your hands away from the blade and always use a push stick or push block to guide the foam board through the saw.

5. Avoid wearing loose clothing or jewelry that may get caught in the saw.

Remember, practicing proper safety measures will help prevent accidents and ensure a smooth and enjoyable cutting experience.

Best Way to Cut XPS Rigid Foam Board

Summary

Cutting foam board with a table saw can be dangerous and difficult. Foam board is lightweight and can easily get caught in the saw, causing kickback and injury. It is best to use alternative methods like a utility knife or hot wire cutter to cut foam board.

However, if you still choose to use a table saw, take safety precautions. Use a push stick to keep your hands away from the blade, and go slow to avoid kickback. Remember to always wear safety goggles and keep the workspace clear of clutter.