Have you ever wondered if you can use a scroll saw to cut foam? Well, you’re in luck because we’re here to answer that very question! Scroll saws are versatile tools known for their precision and ability to create intricate cuts. But can they handle foam? Let’s find out!

Foam is a popular material used in various crafts, upholstery, and even costume making. It’s lightweight, easy to shape, and provides excellent insulation. But when it comes to cutting foam, not all tools are created equal. So, the burning question remains: Can you cut foam with a scroll saw? The short answer is yes, you absolutely can!

Scroll saws equipped with the right blade can effortlessly slice through foam, allowing you to create beautiful and precise designs. Whether you’re working on a DIY project or need to cut upholstery foam for a cushion, a scroll saw can be your trusty companion. So, let’s dive deeper into how to achieve clean and accurate cuts using this fantastic tool!

In this article, we’ll explore the best blades for cutting foam, tips for tackling different types of foam, and important safety precautions to keep in mind. So, grab your scroll saw and let’s discover the world of foam cutting together. Get ready to unleash your creativity and bring your foam projects to life!

Can You Cut Foam with a Scroll Saw?

If you’re a DIY enthusiast or someone who enjoys working with various materials, you might be wondering if a scroll saw is suitable for cutting foam. Foam is a versatile material commonly used in crafting, upholstery, and even construction. It’s known for its softness and flexibility, but can it withstand the precision and power of a scroll saw? In this article, we will explore the possibilities and limitations of using a scroll saw to cut foam, as well as provide you with some tips and tricks for achieving the best results.

What is a Scroll Saw?

A scroll saw is a power tool that is specifically designed for intricate and detailed cuts. It features a fine, narrow blade that moves up and down in a reciprocating motion, allowing the user to make curved and intricate cuts. This makes it a popular choice for woodworking, particularly for creating decorative designs, intricate patterns, and detailed shapes.

While scroll saws are typically used for cutting wood, they can also be used to cut other materials such as plastic, acrylic, and foam. However, it’s important to note that not all scroll saws are created equal, and their capacity to cut foam may vary depending on their power, blade type, and other features. Let’s dive into the specifics of cutting foam with a scroll saw.

The Pros and Cons of Cutting Foam with a Scroll Saw

Before you dive into cutting foam with a scroll saw, it’s essential to understand the advantages and disadvantages of using this tool for this particular material.

The Benefits

1. Precision: Scroll saws are known for their ability to make highly detailed and intricate cuts, which is important when working with foam for crafts or upholstery projects that require precise shapes and designs.

2. Versatility: Foam comes in different thicknesses and densities, and a scroll saw allows you to adjust the speed and blade tension to accommodate various foam materials. This versatility makes it suitable for cutting foam in different projects.

3. Smooth Edges: When used correctly, a scroll saw can create clean and smooth edges on foam, enhancing the overall appearance of your project.

The Drawbacks

1. Blade Selection: Choosing the right blade for cutting foam is crucial. Foam is a relatively soft material, and using a blade with too many teeth per inch (TPI) can cause the foam to tear or melt. On the other hand, using a blade with too few TPI may result in rough or jagged cuts.

2. Dust and Debris: Cutting foam with a scroll saw can generate a significant amount of dust and debris. It’s important to wear a mask and work in a well-ventilated area to avoid inhaling the particles.

3. Noise and Vibration: Scroll saws can be quite noisy and produce vibrations during operation. This might not be ideal if you’re working in a shared or noise-sensitive environment.

Tips for Cutting Foam with a Scroll Saw

If you’ve decided to give cutting foam with a scroll saw a try, here are some tips to help you achieve the best results:

- Choose the right blade: Opt for a blade with a low TPI, ideally between 8 and 12, to prevent tearing or melting of the foam.

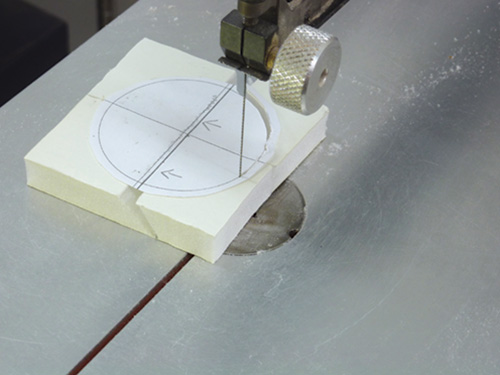

- Secure the foam: Use clamps or adhesive to secure the foam to a stable surface to prevent movement during the cutting process.

- Start with a test piece: Before cutting your actual project, it’s a good idea to practice on a scrap piece of foam to get a feel for the blade and adjust the speed and tension accordingly.

- Take it slow: Foam requires a slower cutting speed compared to harder materials. Take your time and let the blade do the work.

- Support fragile areas: If you’re cutting intricate or fragile foam shapes, consider reinforcing them with a backing material or adhesive to prevent breakage.

- Proper blade maintenance: Properly maintaining and sharpening your scroll saw blades will ensure cleaner cuts and prolong their lifespan.

- Clean up: After cutting foam, be sure to clean the scroll saw and remove any debris to prevent it from affecting future cuts.

Choosing the Right Scroll Saw for Cutting Foam

While most scroll saws can handle cutting foam to some extent, it’s worth considering certain features and specifications when selecting the right tool for the job.

Variable Speed Control

Opt for a scroll saw with variable speed control. This feature allows you to adjust the cutting speed to match the density and thickness of the foam. Slower speeds are preferable for foam cutting to minimize vibrations and prevent melting or tearing.

Throat Size

The throat size refers to the distance between the blade and the back of the saw. A larger throat size provides more space to maneuver the foam during cuts, making it easier to work with larger pieces or intricate designs.

Blade Changing Mechanism

Look for a scroll saw with a quick and easy blade changing mechanism. This feature allows you to switch between blades efficiently, particularly if you need to use different blade types or sizes for different foam projects.

Selecting the Right Blade for Cutting Foam

When it comes to cutting foam with a scroll saw, choosing the right blade is essential. Here are some types of blades that are commonly used for cutting foam:

Skip Tooth Blades

Skip tooth blades have wide gaps between the teeth, allowing for efficient chip removal. These blades are suitable for cutting thicker foam materials or when you need to make fast cuts.

Spiral Blades

Spiral blades have teeth on all sides, allowing for easy cutting in any direction. They are ideal for cutting intricate shapes and designs in foam, as they offer excellent maneuverability.

Reverse Tooth Blades

Reverse tooth blades have teeth that alternate their direction, which helps eliminate tear-out and produce smoother cuts. These blades are suitable for cutting fragile or delicate foam materials.

By selecting the right scroll saw and blade for cutting foam, you can unleash your creativity and achieve precise and professional-looking results. Remember to take the necessary safety precautions and practice on scrap foam before diving into your main project. Happy foam cutting!

Disclaimer: Always follow the manufacturer’s instructions and safety guidelines when operating power tools. Use protective gear, such as safety glasses and a dust mask, to minimize the risk of injury.

Key Takeaways: Can You Cut Foam with a Scroll Saw?

- Yes, you can cut foam with a scroll saw!

- Make sure to use a fine-tooth blade for a clean cut.

- Take your time and go slow to avoid damaging the foam.

- Hold the foam securely in place while cutting to maintain accuracy.

- Consider wearing safety goggles and a mask to protect yourself from foam particles.

Frequently Asked Questions

When it comes to cutting foam with a scroll saw, there are a few things you need to know. Can you cut foam with a scroll saw? Here are some common questions and answers to help you get the job done:

1. Is a scroll saw suitable for cutting foam?

Yes, a scroll saw can be used to cut foam, but it’s important to use the right techniques and tools. Start by choosing the right blade for the job, such as a skip-tooth blade that has wide gaps between the teeth. This will prevent the blade from getting clogged with foam debris. Additionally, it’s crucial to set the scroll saw to a slower speed to ensure smooth and controlled cuts.

Another helpful tip is to use a lubricant, such as silicone spray or paraffin wax, on the blade to reduce friction and prevent the foam from sticking. Finally, make sure to wear safety goggles and a dust mask to protect yourself from foam particles while cutting.

2. Can I cut any type of foam with a scroll saw?

While a scroll saw can cut through many types of foam, it’s recommended to use it primarily for softer foams, such as crafting foam or foam sheets. These types of foam are easier to cut and won’t put excessive strain on the scroll saw blade. If you need to cut denser foams, such as upholstery foam or memory foam, it’s better to use a specialty foam cutting tool or a hot wire cutter for more precise and efficient results.

Remember to always consider the thickness of the foam you’re cutting. Thicker foams may require multiple passes with the scroll saw to prevent excessive resistance and ensure a clean cut.

3. Do I need to secure the foam before cutting with a scroll saw?

Yes, it’s essential to secure the foam to prevent it from moving or vibrating during the cutting process. Unsecured foam can lead to inaccurate cuts and may even pose a safety risk. One simple way to secure the foam is by using double-sided tape to attach it to a sturdy surface, such as a workbench or a piece of plywood. This will provide stability and ensure cleaner cuts.

If you’re working with larger pieces of foam, consider using clamps to hold them in place. This will provide added stability and prevent any unwanted movement while operating the scroll saw.

4. Are there any specific techniques for cutting intricate shapes in foam with a scroll saw?

Absolutely! When cutting intricate shapes in foam with a scroll saw, it’s important to take your time and plan your cuts in advance. Start by outlining the shape you want to cut on the foam and mark any internal cut lines or details. This will serve as a visual guide throughout the cutting process.

For more intricate designs, consider drilling a small hole inside the shape to create a starting point for the scroll saw blade. This makes it easier to maneuver the blade and ensures cleaner cuts. Remember, patience and steady hand movements are key when cutting intricate shapes with a scroll saw.

5. How can I finish the edges of foam after cutting with a scroll saw?

After cutting foam with a scroll saw, the edges might appear rough or jagged. To achieve a smoother finish, you can use sandpaper or a sanding block to gently sand the edges. Start with a coarse-grit sandpaper to remove any large imperfections, and gradually move to finer-grit sandpaper for a smoother finish.

If you’re looking for a more polished look, you can also use a heat gun to lightly heat the edges of the foam. This will cause the foam to melt slightly, resulting in a smoother and more finished appearance.

Cutting Pool Noodles and Foam with a Scroll Saw

Summary

Cutting foam with a scroll saw can be a great option for various projects. However, it’s essential to follow some key tips to ensure success. First, make sure to use the right blade for foam cutting. A fine-tooth blade or a spiral blade works best. Second, go slow and steady when cutting, allowing the saw to do the work. Lastly, be mindful of safety precautions such as wearing goggles and securing the foam properly.

In addition to these tips, it’s good to know that a scroll saw can handle different types of foam, including upholstery foam, craft foam, and expanded polystyrene (EPS) foam. Remember, practice makes perfect, so don’t worry if your first few cuts aren’t flawless. With patience and practice, you’ll be able to create precise and neat foam cuts for your projects. So, go ahead and give it a try!