So you’ve got this burning question in your mind: Can you cut metal on a table saw? Well, let me tell you, my curious friend, that you’ve come to the right place! Today, we’re going to dive into the world of woodworking and explore whether a trusty table saw can handle the challenge of slicing through metal. Get ready to have your mind blown!

Now, before we get into the nitty-gritty, let me paint you a picture. Imagine a table saw—this powerful tool used by craftsmen and DIY enthusiasts alike to make precise cuts in wood. It’s like a superhero with a sharp blade spinning at high speeds, ready to take on any wooden obstacle in its path. But can it stand up to the mighty metal? That’s the real question here.

Well, my eager young reader, the answer isn’t as straightforward as a simple “yes” or “no.” We’ll need to consider a few factors like the type of table saw, the blade you’re using, and the kind of metal you want to cut. So grab your safety goggles and prepare to embark on this thrilling journey where we uncover the secrets of metal cutting with a table saw. Let’s get started!

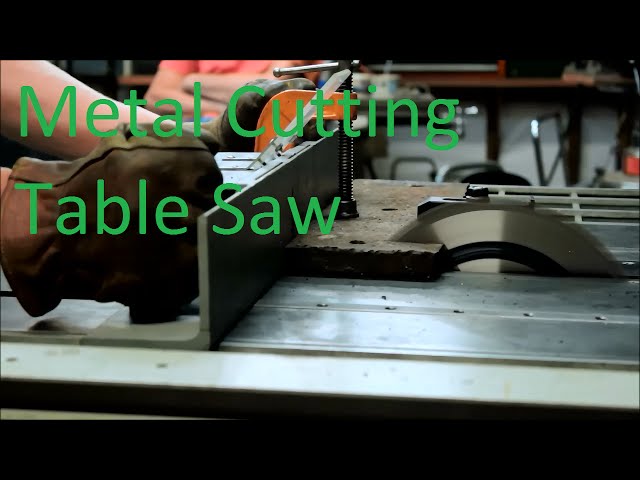

Can You Cut Metal on a Table Saw?

Table saws are versatile tools commonly used for cutting wood, but can they be used for cutting metal as well? Many DIY enthusiasts and professionals wonder if it’s safe and feasible to cut metal on a table saw. In this article, we will explore the possibilities and considerations of using a table saw for cutting metal. From the safety precautions to the types of blades and techniques required, we will provide you with all the information you need to decide whether cutting metal on a table saw is right for you.

Is It Safe to Cut Metal on a Table Saw?

It’s important to note that using a table saw for cutting metal introduces additional risks compared to cutting wood. Metal can create sparks and cause excessive heat buildup, which can be dangerous if not handled properly. Before attempting to cut metal on a table saw, it’s crucial to ensure you have the right safety measures in place. This includes wearing appropriate protective gear such as safety glasses, gloves, and hearing protection. Additionally, a proper table saw setup, including a stable work surface and appropriate safety features, is essential to minimize the risks involved.

1. Safety Precautions When Cutting Metal on a Table Saw

When cutting metal on a table saw, there are several safety precautions that should be followed to minimize risks:

- Use a dedicated metal-cutting blade: A blade specifically designed for cutting metal will minimize the risk of kickback and overheating.

- Secure the metal workpiece: Make sure the metal is securely clamped or held in place to prevent movement during the cutting process.

- Lower the blade height: Adjust the table saw blade to the appropriate height, usually slightly higher than the thickness of the metal being cut.

- Use slow and steady feed rate: Feed the metal through the blade slowly and steadily to maintain control and prevent overheating.

- Keep the work area clear: Remove any debris or chips from the table saw to prevent interference with the cutting process.

By following these safety precautions, you can minimize the risks associated with cutting metal on a table saw and ensure a safer working environment.

2. Types of Blades for Cutting Metal on a Table Saw

The choice of blade is crucial when it comes to cutting metal on a table saw. Using the wrong blade can result in poor cuts, excessive heat buildup, and increased risks. There are two main types of blades suitable for cutting metal on a table saw:

- Carbide-tipped blades: These blades are designed to withstand the rigors of cutting metal and feature teeth with carbide tips for increased longevity. They are effective for cutting thinner sheets of metal, but may struggle with thicker materials.

- Abrasive blades: These blades feature abrasive particles embedded in a resin matrix and are specifically designed for cutting through metal. They are ideal for thicker and harder metals but tend to wear out faster compared to carbide-tipped blades.

When selecting a blade, consider the thickness and type of metal you will be cutting to ensure you choose the right blade for the job.

3. Techniques for Cutting Metal on a Table Saw

Proper techniques are essential when cutting metal on a table saw to ensure precise and safe cuts:

- Use a slow feed rate: As mentioned earlier, feeding the metal through the blade slowly and steadily will prevent kickback and overheating. This will result in cleaner cuts and reduce the risk of accidents.

- Proper blade alignment: Ensure the table saw blade is aligned parallel to the miter gauge or fence to ensure accurate cuts. Misalignment can lead to uneven cuts or kickback.

- Use support for long pieces: When cutting long pieces of metal, use additional support, such as rollers or stands, to prevent sagging and maintain stability.

By implementing these techniques, you can achieve precise and safe cuts when cutting metal on a table saw.

The Benefits of Cutting Metal on a Table Saw

Although cutting metal on a table saw comes with its own set of challenges, there are several benefits to consider:

- Versatility: If you already have a table saw in your workshop, being able to cut metal on it adds versatility to your tool arsenal.

- Cost-effective: Investing in a separate metal-cutting saw can be expensive, especially if you don’t frequently work with metal. Utilizing a table saw you already own can save you money.

- Precision: Table saws are known for their accuracy, which can be advantageous when cutting metal pieces with precise measurements.

These benefits make cutting metal on a table saw an attractive option for many woodworkers and DIY enthusiasts. However, it’s important to weigh the risks and safety precautions before attempting to cut metal on a table saw.

Tips for Safe and Effective Metal Cutting on a Table Saw

To ensure safe and effective metal cutting on a table saw, consider the following tips:

- Start with small projects: If you’re new to cutting metal on a table saw, begin with small and simple projects to gain experience and confidence.

- Practice proper blade maintenance: Regularly clean and inspect your blades to ensure they remain sharp and in good condition. Dull blades can increase the risk of accidents and produce poor cuts.

- Read the manufacturer’s guidelines: Always refer to the manufacturer’s guidelines and recommendations for both your table saw and the metal-cutting blades you use.

Following these tips will help you achieve successful metal cutting results on a table saw while prioritizing safety.

In Conclusion

While it is possible to cut metal on a table saw, it requires careful consideration, appropriate safety measures, and the use of the right blade. By following the safety precautions, selecting the correct blade, and utilizing proper techniques, you can achieve precise and safe cuts when cutting metal on a table saw. However, always prioritize safety and consider the potential risks before attempting this task. Remember, when it comes to working with potentially hazardous materials, safety should never be compromised.

Key Takeaways: Can You Cut Metal on a Table Saw?

– Table saws are designed for cutting wood, not metal.

– Using the wrong blade can damage the table saw and cause accidents.

– It is safer to use specialized tools like a metal-cutting bandsaw or angle grinder.

– Always prioritize safety and use the appropriate tools for different materials.

Frequently Asked Questions

When it comes to table saws, many people wonder if they can be used to cut metal. Here are some common questions and answers related to cutting metal on a table saw:

1. Is it safe to cut metal on a table saw?

While it is technically possible to cut metal on a table saw, it is generally not recommended. Table saws are primarily designed for cutting wood, and using them to cut metal can be dangerous. Metal can cause kickback, damage the blade, and potentially cause injury. It is best to use tools specifically designed for cutting metal.

However, if you have the right blade, proper safety precautions, and experience, it is possible to cut thin sheets of metal using a table saw. It is important to use caution and make sure to follow all safety guidelines to minimize the risks.

2. What type of blade should I use to cut metal on a table saw?

If you do decide to cut metal on a table saw, it is essential to use the right blade. A carbide-tipped blade specifically designed for cutting non-ferrous metals is recommended. These blades have more teeth and are designed to handle the cutting forces generated by metal. Avoid using regular wood-cutting blades, as they are not designed to cut through metal and may cause damage or kickback.

Before cutting metal, make sure the blade is sharp and in good condition. Dull or damaged blades can create more friction and increase the chances of accidents. If you are unsure, consult with a professional or refer to the manufacturer’s recommendations for compatible blades.

3. Can I use a regular table saw fence for cutting metal?

While a regular table saw fence can be used for cutting metal in some cases, it is not optimal. Metal has different properties than wood and may require special care and considerations. It is recommended to use a metal-cutting fence or a guide specifically designed for cutting metal on a table saw. These specialized accessories provide better support and minimize the risk of the metal piece shifting or causing kickback during the cut.

Using a proper fence or guide helps ensure accuracy and improves safety by reducing the chances of the workpiece binding or the blade coming into contact with any part of the table saw that may cause damage or injury.

4. What safety precautions should I take when cutting metal on a table saw?

When cutting metal on a table saw, it is crucial to prioritize safety. Here are some important safety precautions to follow:

First, wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and gloves. Metal can produce sparks, sharp edges, and noise, so protecting yourself is essential.

Make sure the table saw is properly set up and aligned. Check that the blade is securely tightened and adjusted to the correct height for cutting metal. Keep the table surface clean and free from any obstructions that could interfere with the cut or cause the metal to bind.

5. Are there alternative tools for cutting metal?

Yes, there are several alternative tools available for cutting metal that may be safer and more effective than using a table saw. Some popular options include metal-cutting bandsaws, metal-cutting circular saws, and handheld metal cutting shears.

Each of these tools has its own advantages and is specifically designed for cutting metal. They offer better control, accuracy, and safety features compared to using a table saw for cutting metal. Consider your specific needs and the type of metal you are working with to determine the best tool for the job.

Can you cut steel on a table saw?

Summary

So, can you cut metal on a table saw? The answer is yes, but it’s not recommended. Table saws are designed for cutting wood, and using them for metal can be dangerous. Metal has a tendency to create sparks and can cause damage to the saw blade. It’s always better to use the right tools for the job – a metal-cutting bandsaw or angle grinder would be a safer choice. Stay safe and use the appropriate tools for each material you’re working with!