Can you cut metal with a table saw? The answer to this question might surprise you. In this article, we’ll dive into the fascinating world of table saws and explore whether they can be used for cutting metal. If you’ve ever wondered about the capabilities of your trusty table saw, you’re in the right place. Let’s uncover the truth together!

Table saws are versatile tools that are commonly used for woodworking projects. They’re known for their ability to make precise cuts in wood, but can they handle metal too? It’s not uncommon for people to experiment with different materials on their table saws. After all, versatility is key! So, let’s find out if your table saw has what it takes to conquer metal cutting challenges.

Whether you’re a DIY enthusiast or a curious mind, this article will provide you with all the information you need. By the end, you’ll have a clear understanding of whether you can cut metal with a table saw. So, gear up and join us as we explore the possibilities of this powerful tool!

It is possible to cut metal with a table saw, but it requires the right blade and precautions. Follow these steps for successful metal cutting:

- Choose a carbide-tipped or abrasive blade.

- Secure the metal piece tightly, using clamps if necessary.

- Adjust the table saw’s speed and feed rate accordingly.

- Wear protective equipment like safety glasses and gloves.

- Slowly feed the metal through the saw blade, keeping a steady pace.

Remember, safety first! Always read the manufacturer’s instructions and consult an expert if needed.

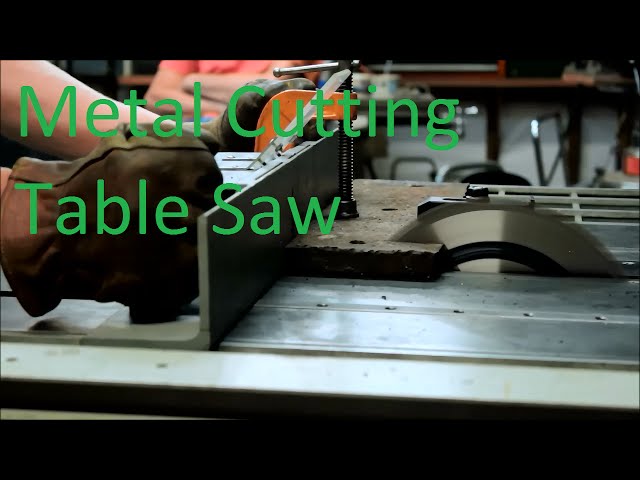

Can You Cut Metal with a Table Saw? Exploring the Possibilities

Have you ever wondered if you can use a table saw to cut metal? Table saws are typically associated with cutting wood, but with the right tools and techniques, you can also make precise cuts in metal. In this article, we’ll delve into the possibilities of cutting metal with a table saw, explore the necessary equipment and safety precautions, and provide you with expert tips to achieve clean and accurate results. So, let’s dive in and discover the potential of your table saw!

The Tools and Equipment You Need for Cutting Metal with a Table Saw

Before you begin cutting metal with a table saw, it’s crucial to have the right tools and equipment to ensure your safety and achieve the best results. Here are the essentials:

1. Table Saw with Appropriate Blade

Your table saw should be equipped with a carbide-tipped or diamond or abrasive blade specifically designed for cutting metal. These blades have a different tooth configuration and durability compared to wood-cutting blades.

2. Protective Wear

Working with metal can be hazardous, so it’s important to protect yourself. Wear safety goggles, a face shield, hearing protection, and gloves to shield your eyes, face, ears, and hands from any potential sparks or metal fragments.

3. Clamps and Guide Fence

For precision and safety, use clamps to secure the metal workpiece firmly to the table. Additionally, a guide fence can help you maintain a straight and accurate cut by acting as a guide for the material.

4. Lubricant

Using a lubricant such as cutting oil or WD-40 can reduce friction and heat generated during the cutting process, leading to smoother, cleaner cuts. Apply the lubricant to the blade and the metal surface to enhance the cutting efficiency.

5. Push Stick or Push Block

To keep your hands at a safe distance from the blade and maintain control during the cut, use a push stick or push block. These tools allow you to push the metal through the saw without the risk of injury.

6. Fire Extinguisher

Although rare, there is always a risk of sparks or heat igniting combustible materials during the cutting process. Having a fire extinguisher nearby is a crucial safety precaution to quickly extinguish any potential fires.

7. Metal-Cutting Techniques and Tips

Now that you have the necessary tools and equipment, let’s explore some essential techniques and expert tips to ensure successful metal cutting with your table saw:

1. Maintain Safety First

Always prioritize safety when working with any power tools. Familiarize yourself with the manufacturer’s guidelines and recommendations for your specific table saw model. Wear your protective gear, follow proper safety protocols, and work in a clean and well-ventilated area.

2. Choose the Right Blade

Select a blade specifically designed for cutting metal. Carbide-tipped blades with a higher tooth count or diamond or abrasive blades are ideal for clean and precise cuts. Ensure the blade fits securely on your table saw and is sharp enough for optimal performance.

3. Measure and Mark Precisely

Accurate measurements and clear markings are crucial when cutting metal. Use a combination square, ruler, or measuring tape to mark the desired cut line directly onto the metal. Double-check your measurements to ensure accuracy before proceeding with the cut.

4. Secure the Workpiece

Using clamps or a vice, secure the metal workpiece firmly to the table to prevent any movement during the cutting process. This will ensure stability and help you achieve straight and accurate cuts.

5. Adjust the Table Saw Settings

Set the blade height to slightly above the thickness of the metal sheet or workpiece. Adjust the angle and the fence according to the desired cut. It’s essential to make precise adjustments based on the metal’s thickness and the type of cut you need.

6. Lubricate for Smooth Cuts

Apply a lubricant, such as cutting oil or WD-40, to the blade and the metal surface. This lubrication reduces friction and heat, allowing the blade to cut smoothly through the metal. Reapply the lubricant periodically during the cutting process for optimal results.

7. Use a Slow and Steady Approach

When cutting metal with a table saw, it’s crucial to feed the material slowly and steadily through the blade. Do not rush the process, as this can lead to jagged or uneven cuts. Maintain a consistent pace while applying gentle pressure to achieve clean and precise cuts.

Exploring the Benefits of Cutting Metal with a Table Saw

While it may not be the conventional use for a table saw, cutting metal with this versatile tool offers numerous benefits:

1. Cost-Effective Solution

Investing in a table saw for cutting metal can be a cost-effective alternative to purchasing a dedicated metal-cutting machine. Properly equipping your table saw with the necessary tools and safety gear allows you to expand its capabilities while maximizing your investment.

2. Precision and Accuracy

Table saws are renowned for their ability to make precise and accurate cuts. With a stable work surface and appropriate blade, you can achieve clean, straight, and accurate cuts in metal, allowing for more intricate and refined projects.

3. Versatility in Materials

Cutting metal with a table saw grants you the freedom to work with a variety of materials, including aluminum, steel, brass, and copper. This versatility allows you to explore different projects and expand your creative boundaries.

4. Efficiency and Time Savings

Table saws offer quick and efficient cutting capabilities. With the ability to adjust the speed and feed rate, you can significantly reduce cutting time compared to manual methods. This efficiency translates to increased productivity and more time for other aspects of your projects.

Can You Cut Stainless Steel with a Table Saw?

Stainless steel is a commonly used material in various industries, and being able to cut it accurately and efficiently can be beneficial. While a table saw can cut some thin stainless steel sheets, it is generally not recommended for thicker or hardened stainless steel. The hardness and composition of stainless steel can cause excessive wear on the blade, resulting in decreased performance and potentially hazardous conditions.

Safety Precautions when Cutting Metal with a Table Saw

When using a table saw for cutting metal, it is essential to prioritize safety at all times. Here are some key safety precautions to keep in mind:

1. Protective Gear

Wear safety goggles, a face shield, hearing protection, and gloves to protect yourself from potential sparks or metal fragments. Avoid loose clothing or jewelry that could get caught in the saw.

2. Adequate Ventilation

Ensure you work in a well-ventilated area or use a dust collection system to minimize the inhalation of metal dust or fumes.

3. Proper Lighting

Make sure your work area is well-lit to help you see any potential hazards or obstructions clearly.

4. Secure the Material

Always secure the metal workpiece tightly using clamps or a vice to prevent it from moving during the cutting process.

5. Go Slow and Steady

Feed the metal through the saw slowly and steadily to maintain control and minimize kickback. Avoid forcing the material or applying excessive pressure.

6. Clean the Workspace

Regularly clean the saw table and remove any debris or metal shavings that may interfere with the cut or cause slippage.

7. Use a Push Stick or Block

To keep your hands safe, use a push stick or block to guide the metal through the blade, keeping your hands at a safe distance.

Conclusion:

While cutting metal with a table saw requires the right tools, techniques, and safety precautions, it is indeed possible to achieve clean and precise cuts. With the appropriate blade, protective gear, and guidance, your table saw can become a versatile tool for various materials, including metal. Remember to prioritize safety, follow the manufacturer’s instructions, and take your time to ensure accurate results. So, unleash the full potential of your table saw and explore the world of metalwork with confidence and creativity!

Key Takeaways: Can You Cut Metal with a Table Saw?

- Yes, you can cut metal with a table saw, but it is not recommended.

- Table saws are primarily designed for cutting wood and may not have appropriate safety features for metal cutting.

- Using a metal-cutting blade and appropriate safety precautions can help mitigate the risks associated with metal cutting on a table saw.

- However, the high speed and power of a table saw can still pose challenges when cutting metal.

- It is generally recommended to use a dedicated metal-cutting tool, such as a bandsaw or a metal chop saw, for cutting metal.

Frequently Asked Questions

In this section, we will address commonly asked questions about cutting metal with a table saw.

1. Can a table saw cut metal?

Yes, a table saw can cut metal. However, it’s important to note that not all table saws are designed to cut metal. If you want to cut metal with a table saw, you will need to use a specialized blade that is specifically designed for cutting through metal. These blades are typically made from materials like carbide or diamond and have teeth that are designed to cut through metal effectively. It’s not recommended to use a regular wood-cutting blade to cut metal as it can be dangerous and can damage the blade.

When using a table saw to cut metal, it’s important to take appropriate safety precautions. Make sure to wear appropriate safety gear, such as safety glasses and gloves, and secure the metal firmly before cutting. Also, be aware that cutting metal may produce sparks, so it’s important to work in a well-ventilated area and keep flammable materials away from the cutting area.

2. What types of metal can be cut with a table saw?

A table saw can generally be used to cut through various types of metal, including aluminum, brass, copper, and steel. However, the thickness and hardness of the metal will impact the type of blade and cutting technique you need to use. Thicker and harder metals may require a more powerful table saw and specialized blades, while thinner and softer metals can be cut with standard metal-cutting blades.

It’s important to choose the right blade for the specific type of metal you are cutting. Different metal-cutting blades are designed to work best with different types of metal, so be sure to select a blade that matches the material you are working with.

3. What safety precautions should be taken when cutting metal with a table saw?

When cutting metal with a table saw, it’s crucial to prioritize safety. Here are some important safety precautions to follow:

– Always wear appropriate safety gear, including safety glasses, gloves, and ear protection.

– Secure the metal firmly in place before making any cuts to prevent it from moving or shifting during cutting.

– Use a specialized blade that is designed for cutting metal and ensure it is properly installed and tightened.

– Work in a well-ventilated area to minimize the risk of sparks igniting flammable materials.

– Avoid wearing loose clothing or jewelry that could get caught in the blade.

By following these safety precautions, you can minimize the risk of accidents and injuries while cutting metal with a table saw.

4. Can I use a regular wood-cutting blade to cut metal with a table saw?

It is not recommended to use a regular wood-cutting blade to cut metal with a table saw. Wood-cutting blades are specifically designed for cutting through wood and are not suitable for cutting metal. The teeth of a wood-cutting blade are designed to rip through wood fibers, and using it on metal can cause the blade to seize, kickback, or become damaged. Additionally, cutting metal with a wood-cutting blade can be dangerous as it may result in flying debris.

If you want to cut metal with a table saw, it’s important to invest in a specialized blade that is designed for cutting metal. These blades are made from materials like carbide or diamond and have teeth that are specifically designed to cut through metal with precision and efficiency. Using the correct blade will help ensure clean and accurate cuts while maintaining safety.

5. Can a regular table saw handle cutting thick metal sheets?

A regular table saw may not be suitable for cutting thick metal sheets. Table saws are typically designed for cutting wood and may not have the power or capacity to handle thick metal sheets. For cutting thicker metal sheets, you may need to use a heavier-duty table saw with a more powerful motor. Additionally, specialized metal-cutting table saws or other tools, such as plasma cutters or metal shears, may be better suited for cutting thick metal sheets.

It’s important to assess the capabilities of your specific table saw and determine if it is suitable for the thickness of metal you intend to cut. If your table saw is not built for cutting thick metal sheets, it’s best to explore alternative tools or seek professional assistance to ensure safe and accurate cuts.

Summary

Cutting metal with a table saw is not recommended because it can be dangerous. Table saws are designed for wood, and cutting metal can cause sparks and damage the machine. It is best to use appropriate tools like a metal cutting saw or angle grinder for metal cutting projects.

If you try cutting metal with a table saw, it can lead to accidents and injuries. The blade can get damaged, and the metal pieces can fly off, causing harm to you or others nearby. To ensure safety and a clean cut, always use the right tools for the job.