Metalworking enthusiasts, have you ever wondered if you can cut stainless steel with a bandsaw? Well, you’ve come to the right place! In this article, we’ll explore the fascinating world of using a bandsaw for cutting stainless steel. So grab your safety goggles and let’s dive right in!

Now, you might be thinking, “Why use a bandsaw?” Great question! Bandsaws are versatile and powerful tools that can make quick work of cutting through various materials. But can they handle stainless steel? That’s the million-dollar question we’re here to answer.

Whether you’re a seasoned DIYer or just starting out, we’ll break down the process and share all the ins and outs of cutting stainless steel with a bandsaw. So buckle up and get ready to unleash your inner metal-cutting ninja! Let’s get started!

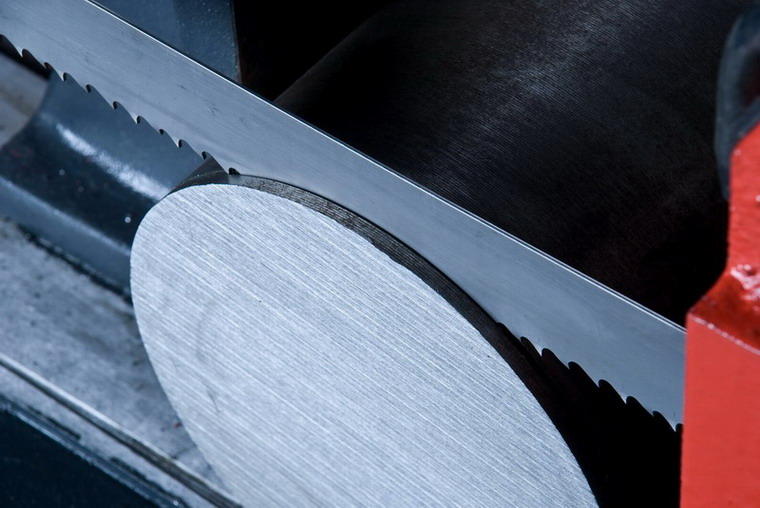

Looking to cut stainless steel? A bandsaw is a versatile tool that can make the task easier. With the right blade and technique, cutting stainless steel with a bandsaw is possible. Ensure you use a bi-metal bandsaw blade designed for cutting metal. Adjust the speed and feed rate to prevent overheating and ensure a smooth cut. Remember to wear safety gear, including gloves and goggles. Always practice caution and follow manufacturer guidelines for best results.

Can You Cut Stainless Steel with a Bandsaw?

Stainless steel is a durable and popular material used in various industries for its corrosion resistance and strength. When it comes to cutting stainless steel, there are several methods to choose from, and one of them is using a bandsaw. In this article, we will explore whether a bandsaw is a suitable tool for cutting stainless steel, its pros and cons, and how to effectively use it for this purpose.

The Pros and Cons of Using a Bandsaw to Cut Stainless Steel

A bandsaw is a versatile cutting tool that can be used for various materials, including wood, metal, and plastic. However, when it comes to cutting stainless steel, there are both advantages and disadvantages to consider.

Advantages of Using a Bandsaw

1. Cutting Accuracy: Bandsaws provide precise and clean cuts, making them ideal for projects that require a high level of precision.

2. Versatility: Bandsaws can be equipped with different types of blades, allowing you to cut various thicknesses and types of stainless steel.

3. Efficiency: Bandsaws are designed to cut through metal quickly, making them a time-saving option for stainless steel cutting projects.

Disadvantages of Using a Bandsaw

1. Limited Thickness Capacity: Bandsaws have a maximum cutting capacity, which means they may not be suitable for cutting thicker pieces of stainless steel.

2. Heat Generation: The cutting process generates heat, and while bandsaws have coolant systems, they may not be sufficient for cutting stainless steel without causing overheating.

3. Blade Selection: Choosing the right blade for cutting stainless steel on a bandsaw can be challenging. The wrong blade could result in poor cutting performance or damage to the material.

How to Effectively Use a Bandsaw to Cut Stainless Steel

While using a bandsaw to cut stainless steel can be a viable option, there are certain techniques and tips you should follow to ensure optimal results. Here’s a step-by-step guide:

Step 1: Selecting the Right Blade

Choosing the right blade is crucial for successful stainless steel cutting. Opt for a bi-metal or carbide-tipped blade specifically designed for cutting metal. Ensure the blade has the appropriate tooth pitch and thickness for the stainless steel thickness you’re working with.

Step 2: Preparing the Bandsaw

Before cutting stainless steel, ensure your bandsaw is properly set up. Check the tension of the blade, align the blade guides, and adjust the feed rate for optimal cutting performance. Additionally, make sure the coolant system is in good working condition to prevent overheating.

Step 3: Securing the Stainless Steel

Secure the stainless steel material firmly in place, using clamps or a vise, to ensure stability during the cutting process. This will help prevent accidents and ensure accurate cuts.

Step 4: Cutting Technique

When cutting stainless steel on a bandsaw, it’s important to use a slow and steady feed rate. Apply light pressure on the material and let the blade do the cutting. Avoid forcing the stainless steel through the blade, as it can cause blade damage or poor cutting quality.

Step 5: Monitoring and Cooling

While cutting, monitor the cutting area for any signs of overheating or blade dullness. If you notice excessive heat or decreased cutting efficiency, stop and allow the material and blade to cool. You may also need to periodically apply a suitable coolant to prevent overheating.

Step 6: Finishing Touches

Once the cut is complete, inspect the stainless steel for any rough edges or burrs. Use a deburring tool or file to smooth out the edges and achieve the desired finish.

Conclusion

Cutting stainless steel with a bandsaw can be an effective method, providing you have the right blade, proper setup, and follow the recommended techniques. However, it’s important to consider the limitations of a bandsaw, such as thickness capacity and heat generation. By carefully selecting the appropriate blade, setting up your bandsaw correctly, and employing the right cutting techniques, you can achieve precise and clean cuts in stainless steel with a bandsaw.

Can You Cut Stainless Steel with a Bandsaw?

Yes, you can cut stainless steel with a bandsaw, but it requires the right blade and setup.

Key takeaways:

- Choose a bi-metal or carbide-tipped bandsaw blade for cutting stainless steel.

- Ensure the blade is tensioned correctly and the speed is optimal.

- Use cutting fluid or lubricant to reduce heat and extend blade life.

- Take safety precautions like wearing protective gear and securing the workpiece.

- Consider consulting an expert or practicing on scrap metal before attempting a project.

Frequently Asked Questions

Wondering if a bandsaw can cut through stainless steel? Look no further! Here are the most commonly asked questions about cutting stainless steel with a bandsaw.

1. What type of bandsaw blade should I use to cut stainless steel?

When cutting stainless steel with a bandsaw, it is crucial to use a blade specifically designed for cutting metal. Opt for a bi-metal blade with high-speed steel teeth and a variable tooth pitch. This type of blade is designed to withstand the hardness and toughness of stainless steel, providing clean cuts and extended blade life.

Remember to choose a blade with the appropriate width for your bandsaw to ensure efficient cutting and minimal vibration. Consult the manufacturer’s guidelines or speak to a bandsaw expert to determine the best blade for your specific cutting needs.

2. Can I use a regular bandsaw to cut stainless steel?

While it’s technically possible to use a regular bandsaw to cut thin sheets of stainless steel, it is not recommended. Regular bandsaws are typically designed for woodcutting and may not have the power, speed, or strength to cut through stainless steel effectively.

Using a regular bandsaw with the wrong blade can cause excessive wear and tear, blade damage, and even safety hazards. It’s best to invest in a bandsaw specifically designed for cutting metal, such as stainless steel, to ensure accurate cuts and a longer lifespan for your equipment.

3. How do I set the bandsaw speed and feed rate for cutting stainless steel?

When cutting stainless steel with a bandsaw, it’s important to set the appropriate speed and feed rate to achieve optimal results. Generally, a slower blade speed is preferred for stainless steel as it reduces heat build-up and helps prevent work hardening.

As for the feed rate, start with a moderate rate and adjust as needed based on the thickness and type of stainless steel you are cutting. It’s essential to find the right balance between the speed and feed rate to maintain a smooth cutting process while avoiding blade damage or premature wear.

4. What safety precautions should I take when cutting stainless steel with a bandsaw?

Cutting stainless steel with a bandsaw involves potential risks, so taking proper safety precautions is vital. Always wear protective gear such as safety glasses, gloves, and a face shield to shield yourself from metal shavings and flying debris.

Secure the stainless steel firmly using clamps or a vise to prevent it from moving while cutting. It’s also important to ensure the bandsaw is in good working condition, with the blade tensioned properly and the guards in place. Finally, take breaks when necessary to prevent overheating of the blade and the material being cut.

5. Are there any tips for achieving clean and accurate cuts when cutting stainless steel with a bandsaw?

Achieving clean and accurate cuts when cutting stainless steel with a bandsaw requires attention to detail and some helpful tips. First, make sure the stainless steel is securely positioned to prevent vibrations and ensure a straight cut.

Using cutting fluids or lubricants specifically designed for metal cutting can also help reduce friction and heat, resulting in smoother cuts. Additionally, regularly inspect and replace dull blades to maintain optimum cutting performance. Lastly, practice proper technique and maintain a steady pace while feeding the material into the bandsaw.

Summary

Cutting stainless steel with a bandsaw is possible but requires the right blade. Bandsaws with bi-metal blades are the best choice.

Stainless steel’s hardness can cause regular blades to wear quickly, so a higher tooth count is recommended. Cutting at slower speeds with lubrication also helps reduce heat and maintain cut quality. Overall, with the right blade and technique, a bandsaw can cut stainless steel effectively.