Have you ever had the frustration of a broken drill bit while working on a project? Well, the good news is that there might be a solution! In this article, we’re going to explore the question: “Can you drill out a broken drill bit?”

Now, I know what you’re thinking: “Wait, can you really drill out a broken drill bit?” Well, my friend, the answer is not as straightforward as you might think. It depends on a few factors, and we’re here to break it down for you.

So, if you’re curious to find out whether it’s possible to salvage a broken drill bit and get back to your project, keep reading! We’ll be diving into the details and providing you with the information you need. Let’s get started, shall we?

Can You Drill Out a Broken Drill Bit?: A Comprehensive Guide

Welcome to our comprehensive guide on drilling out broken drill bits! Whether you’re a DIY enthusiast or a professional tradesperson, encountering a broken drill bit is a frustrating situation. But fear not, because in this article, we will explore the various methods and techniques to effectively drill out a broken drill bit. So, if you’ve been wondering whether it’s possible to remove a broken drill bit and how to do it, you’ve come to the right place. Let’s dive in!

Methods for Drilling Out a Broken Drill Bit

When it comes to removing a broken drill bit, there are several methods you can employ. Each method has its own advantages and considerations, so it’s important to choose the one that suits your specific situation. Here are three popular methods for drilling out a broken drill bit:

Method 1: Using a Left-Handed Drill Bit

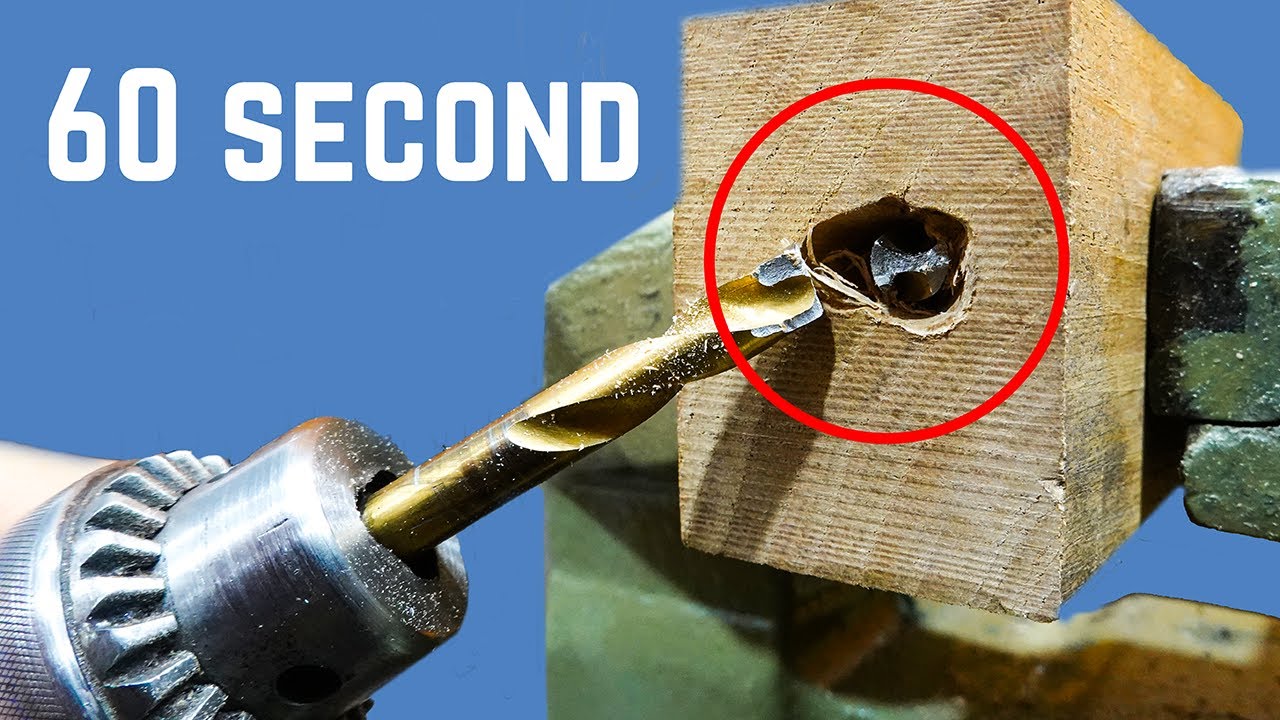

Using a left-handed drill bit is one of the most common methods for drilling out a broken drill bit. These specialized drill bits have a reverse cutting pattern, which means they turn counterclockwise. The idea behind this method is that as you drill into the broken drill bit, the reverse cutting pattern creates torque that helps to loosen the broken piece, making it easier to remove.

To use a left-handed drill bit, follow these steps:

- Secure the workpiece in a vice or clamp to keep it steady.

- Select a left-handed drill bit that is slightly smaller than the broken drill bit.

- Carefully position the drill bit at the center of the broken piece.

- Set the drill to reverse and apply gentle pressure as you begin drilling.

- Monitor your progress and stop drilling once the broken piece starts to loosen.

- Use pliers or a similar tool to extract the broken drill bit.

While this method can be effective, it’s important to note that it may not work in all situations. If the broken drill bit is lodged too tightly or the material is especially hard, you may need to explore alternative methods.

Method 2: Using a Screw Extractor

If the left-handed drill bit method fails or is not suitable for your situation, using a screw extractor is another option to consider. A screw extractor is a specialized tool designed to grip the broken piece and rotate it counterclockwise as you turn it with a wrench or drill. It’s important to match the size of the screw extractor to the size of the broken drill bit for optimal results.

Follow these steps to use a screw extractor:

- Choose an appropriate-sized screw extractor for the broken drill bit.

- Using a drill or wrench, carefully turn the screw extractor counterclockwise to embed it into the broken drill bit.

- Apply consistent pressure as you turn the screw extractor to gradually loosen the broken piece.

- Once the broken drill bit is sufficiently loosened, use pliers or a similar tool to extract it.

Screw extractors can be highly effective, particularly if the broken drill bit is firmly embedded in the material. However, it’s essential to proceed with caution and ensure you have the appropriate tools and skills to avoid further damage to the workpiece or injury to yourself.

Method 3: Using a Tungsten Carbide Drill Bit

If the previous methods don’t yield the desired results, using a tungsten carbide drill bit is another viable option. Tungsten carbide is an extremely hard and durable material that can effectively drill through hardened steel, making it suitable for removing broken drill bits stuck in tough materials.

To use a tungsten carbide drill bit, adhere to the following steps:

- Select a tungsten carbide drill bit that matches the size of the broken drill bit or is slightly larger.

- Ensure the workpiece is securely clamped or held in place to prevent movement during drilling.

- Apply cutting fluid or lubricant to the area to reduce heat and friction.

- Start drilling at a low speed and gradually increase to maintain control and prevent overheating.

- Monitor your progress and stop drilling once you’ve reached the broken piece.

- Gently pry or extract the broken drill bit using pliers or a similar tool.

Using a tungsten carbide drill bit requires patience and precision, as excessive force or incorrect drilling techniques can lead to further complications. It’s crucial to prioritize your safety and take the necessary precautions when employing this method.

Preventive Measures and Tips

Now that you’ve learned how to effectively drill out a broken drill bit, it’s important to address preventive measures and tips to avoid encountering this issue in the future. Here are some handy tips to help you minimize the chances of breaking a drill bit:

Tip 1: Use the Right Drill Bit for the Job

Choosing the correct drill bit for the material you’re working with is crucial. Different materials require different types and hardness levels of drill bits. Using the wrong drill bit can increase the likelihood of breakage.

Tip 2: Use Lubrication

When drilling through particularly tough materials or metals, applying lubrication or cutting fluid can significantly reduce heat and friction. This helps prolong the life of your drill bit and reduces the risk of breakage.

Tip 3: Work at a Suitable Speed

Rushing through a drilling task can lead to excessive heat and pressure, causing your drill bit to break. Take your time, work at a manageable speed, and let the drill bit do the work.

Tip 4: Secure the Workpiece

Ensure your workpiece is securely clamped or held in place before beginning any drilling. This minimizes vibrations and movement that can increase the chance of a broken drill bit.

Tip 5: Regularly Inspect and Maintain Your Drill Bits

Performing routine inspections and maintenance on your drill bits is essential. Check for signs of wear, such as dullness or chipping, and replace them when necessary. Keeping your drill bits in optimal condition can prevent unexpected breakages.

By implementing these preventive measures and adhering to the appropriate techniques, you can reduce the likelihood of encountering broken drill bits in your future projects.

Conclusion

Drilling out a broken drill bit is indeed possible, and with the right tools, techniques, and proper precautions, it can be a relatively straightforward process. Whether you opt for a left-handed drill bit, a screw extractor, or a tungsten carbide drill bit, it’s crucial to approach the task with patience and precision. Additionally, by implementing preventive measures and following the tips provided, you can minimize the chances of experiencing a broken drill bit in the first place. Remember, safety should always be a top priority when working with power tools. Happy drilling!

Key Takeaways: Can You Drill Out a Broken Drill Bit?

- Yes, it’s possible to drill out a broken drill bit.

- You’ll need a left-handed drill bit and a drill press for best results.

- Start by center-punching the broken drill bit to create a guide for drilling.

- Use a slow speed and gradually increase the pressure as you drill out the broken bit.

- Be patient and take breaks to avoid overheating the drill bit or damaging the surrounding material.

Frequently Asked Questions

Have you ever had a broken drill bit that needed to be removed? Here are some common questions people have about drilling out broken bits:

1. Can you remove a broken drill bit without damaging the material?

Absolutely! It is possible to remove a broken drill bit without causing any damage to the material it’s stuck in. One method is to use a left-hand drill bit. These drill bits rotate in the opposite direction as regular drill bits, which can help loosen and remove the broken piece. Another option is using an extractor. These specialized tools are designed to grip onto the broken bit, allowing for easy removal without damaging the material.

However, it’s important to note that removing a broken drill bit can sometimes be a delicate process, especially if it is lodged in a fragile material like ceramics or glass. In such cases, it may be wise to seek professional assistance to minimize the risk of further damage.

2. What should I do if the broken drill bit is stuck really tight?

If the broken drill bit is stuck tightly and traditional methods don’t seem to be working, don’t panic. There are a few tricks you can try. First, apply some penetrating oil or rust dissolver to help loosen the bit. Allow it to sit for a while and try again using a left-hand drill bit or extractor. If it’s still stuck, you can try gently tapping the broken piece with a hammer to create vibrations that might dislodge it.

If all else fails, it may be necessary to use a drill bit extraction tool. These tools are specifically designed to remove stuck or broken drill bits. They typically work by creating a reverse torque that helps release the bit. It’s important to use these tools with caution and follow the instructions carefully to avoid causing any further damage.

3. Is it possible to drill out a broken bit made of hardened steel?

Drilling out a broken drill bit made of hardened steel can be a challenging task. Due to the hardness of the material, regular drill bits may struggle to make any progress. However, there are specialized drill bits available, such as cobalt or carbide drill bits, that are designed to drill into hardened materials.

When working with hardened steel, it’s important to use slow and steady drilling pressure. Applying excessive force or drilling at high speeds can result in the bit overheating, losing its cutting ability, or even breaking. It’s also crucial to use the correct drill bit size and cutting fluid to ensure the best chances of success and minimize the risk of damaging the workpiece or the drill itself.

4. Can a broken drill bit be removed from concrete or masonry surfaces?

Yes, broken drill bits can be removed from concrete or masonry surfaces, but it requires a different approach compared to other materials. To remove a broken bit from concrete or masonry, you can use a hammer and chisel to carefully chip away the surrounding material until the broken bit becomes exposed. Once exposed, you can use pliers or an extractor tool to remove the broken piece.

It’s important to be patient and work slowly when removing a broken bit from concrete or masonry. Rushing the process or applying excessive force can result in further damage to the surface or the drill itself. If you’re unsure about the best method to use or if the bit is deeply embedded, it’s recommended to consult a professional for assistance.

5. Can I prevent drill bits from breaking in the first place?

While accidents can happen, there are a few tips to help prevent drill bit breakage. Firstly, make sure you’re using the right drill bit for the material you’re working on. Different drill bits are designed for different materials, and using the correct one will minimize the risk of breakage.

It’s also important to use the appropriate drilling speed and pressure. Applying too much pressure or drilling too fast can cause excessive heat, which can lead to breakage. Always start drilling at a slow speed and gradually increase as needed. Additionally, regularly inspect your drill bits for signs of wear or damage, and replace them as necessary to maintain optimal performance.

**Summary**

If you find yourself with a broken drill bit, don’t worry! There are a few simple steps you can take to drill it out and get back to work. First, make sure you have the right tools on hand, like a reverse drill bit or left-hand drill bit. Then, carefully center the bit on the broken piece and apply gentle pressure. Slowly drill into the broken bit, being cautious not to go too fast or apply too much force. With a bit of patience and care, you’ll be able to remove that broken drill bit and continue your project.

Remember, prevention is the best cure, so always take proper precautions when drilling to avoid breaking your drill bit. Use the right drill speed and pressure, and make sure your drill bit is in good condition. And in case you do come across a broken drill bit, now you know you have options to safely remove it and keep on drilling. Happy drilling!