Have you ever wondered if you can drill out a drill bit? Well, get ready to learn something fascinating! In this article, we’ll explore the possibility of using a drill to remove material from a drill bit itself. Yes, you read that right!

Now, before we dive into the nitty-gritty, let’s make sure we’re on the same page. You may be familiar with drill bits – those pointy tools used to create holes in various materials. But can you imagine using a drill to modify and reshape one of these bits? It might sound unconventional, but it’s a question worth exploring.

So, grab your curiosity and let’s find out if it’s possible to drill out a drill bit!

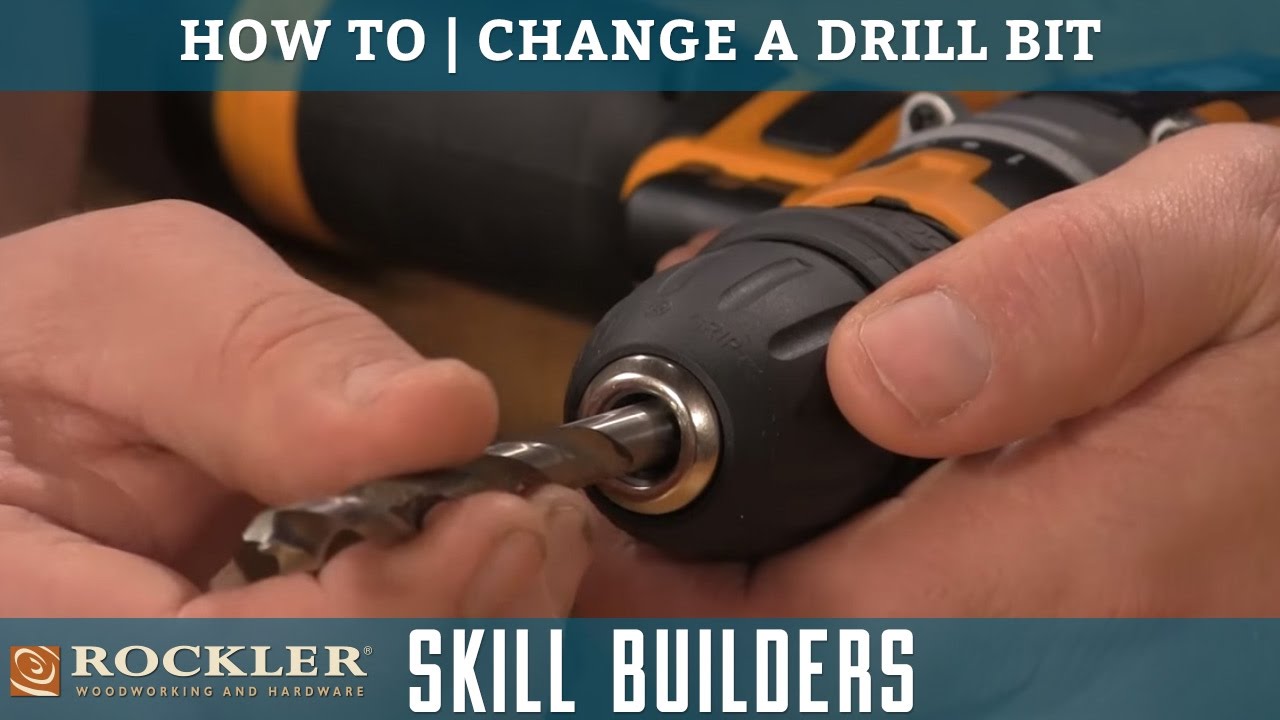

Yes, you can drill out a drill bit! Sometimes, drill bits may become dull or break, making it necessary to remove them from the drill. To do this, follow these steps:

- Secure the drill bit using a vise grip.

- Select a drill bit of the desired size.

- Center the new drill bit on top of the broken one.

- Grip both bits tightly together.

- Using a drill, rotate the new bit counterclockwise to remove the old one.

Can You Drill Out a Drill Bit?

Drill bits are essential tools for any handyman or DIY enthusiast. They help us create holes in various materials with precision and ease. But what happens when a drill bit becomes dull or breaks? Can you salvage it by drilling it out? In this article, we will explore this question and provide you with detailed information about whether it is possible to drill out a drill bit.

Factors to Consider Before Drilling Out a Drill Bit

Before jumping into the process of drilling out a drill bit, let’s consider a few factors that are important to keep in mind:

1. Material of the Drill Bit

The material of the drill bit plays a crucial role in determining whether it can be drilled out. Drill bits are typically made from high-speed steel (HSS), cobalt steel, or carbide. HSS and cobalt steel drill bits are more common and can often be drilled out using the appropriate tools and techniques. However, carbide drill bits, which are known for their extreme hardness and durability, are much more challenging to drill out and may require specialized equipment.

2. Size and Type of the Drill Bit

The size and type of the drill bit also affect its drillability. Smaller drill bits with a simpler design are generally easier to drill out compared to larger or more complex drill bits. For example, a small twist drill bit without any specialized features can be drilled out relatively easily. On the other hand, a larger or specialty drill bit, such as a step drill bit or a spade drill bit, may pose more challenges.

3. Degree of Damage or Dulling

The extent of damage or dulling to the drill bit also plays a role in determining whether it can be drilled out. If only a small portion of the drill bit is damaged, it might be possible to remove the damaged section by drilling it out carefully. However, if the drill bit is significantly broken or extensively dulled, it may be more cost-effective to replace it instead of attempting to drill it out.

Methods for Drilling Out a Drill Bit

If you’ve assessed the factors mentioned above and determined that drilling out the drill bit is worth attempting, here are a few methods you can consider:

1. Using a Drill Bit Extractor

A drill bit extractor is a specialized tool designed to remove broken or damaged drill bits from a workpiece. It typically consists of a hardened steel guide that is inserted into the workpiece and a reverse-threaded drill bit that grabs the broken drill bit and unscrews it. Using a drill bit extractor can be an effective method for drilling out a drill bit, especially if the bit is broken or stuck.

2. Using a Left-Handed Drill Bit

Another option is to use a left-handed drill bit. Left-handed drill bits are designed to rotate counterclockwise and have a spiral flute pattern that can help to grab and remove a broken or damaged drill bit. By drilling a small hole into the center of the broken drill bit using a left-handed drill bit, you can create a pathway for it to be easily extracted.

3. Seeking Professional Help

If the above methods seem daunting or you’re dealing with a particularly challenging situation, it is always advisable to seek professional help. Professional tool sharpening or repair services have the expertise and specialized tools required to safely drill out a drill bit, especially if it is made from carbide or other hardened materials.

Remember, drilling out a drill bit should be seen as a last resort. Regular maintenance, proper usage, and careful handling of drill bits can help prolong their lifespan and prevent the need for drilling them out. If a drill bit becomes excessively dull or damaged, it is often more practical and cost-effective to replace it with a new one.

The Importance of Proper Drill Bit Maintenance

To ensure the longevity and performance of your drill bits, it is crucial to practice proper maintenance. Here are a few tips to keep in mind:

1. Use the Right Speed and Pressure

Using the appropriate speed and applying consistent pressure while drilling can help prevent excessive heat buildup and premature dulling of the drill bit. Refer to the manufacturer’s guidelines for recommended operating speeds and techniques for different materials.

2. Lubricate When Necessary

When drilling through certain materials like metal or hardwood, lubrication can help reduce friction and heat. This can prevent the drill bit from becoming too hot and losing its sharpness. Use cutting oils or lubricants specifically designed for drilling applications.

3. Clean and Store Properly

After each use, make sure to clean off any debris or residue from the drill bit. This can be done using a brush or by blowing compressed air over it. Store your drill bits in a dry and organized manner, preferably in a case or container that protects them from moisture and unnecessary physical stress.

By following these maintenance practices, you can maximize the lifespan of your drill bits and minimize the need for potentially challenging procedures like drilling them out.

Conclusion

In summary, while it is possible to drill out a drill bit under certain circumstances, it should generally be considered a last resort. Factors such as the material of the drill bit, its size and type, and the extent of damage or dulling should be carefully evaluated before attempting to drill it out. Employing specialized tools and techniques like drill bit extractors or left-handed drill bits may aid in the process. However, it is essential to prioritize regular maintenance and proper usage to avoid the need for drilling out drill bits in the first place.

Key Takeaways: Can You Drill Out a Drill Bit?

- Yes, you can drill out a damaged drill bit to restore its functionality.

- Start by securing the damaged drill bit in a vice grip to keep it steady.

- Use a center punch to create a small indentation on the broken part of the drill bit.

- Select a drill bit slightly larger than the diameter of the broken piece.

- Slowly drill out the broken part, applying constant pressure and reducing the drill speed if necessary.

Frequently Asked Questions

When it comes to drilling, many questions may arise. Here are some commonly asked questions and their answers.

How can I remove a jammed drill bit from a material?

Removing a jammed drill bit can be frustrating, but with the right approach, it can be done. Start by using a pair of pliers to firmly grip the shank of the drill bit. Then, try rotating it counterclockwise to loosen it. If it doesn’t budge, apply gentle pressure while tapping the back of the drill bit with a hammer. This can help dislodge any debris or loosen the grip. If these methods don’t work, you can consider using a drill bit extractor tool, specifically designed for removing stuck drill bits.

Remember to use caution when attempting to remove a jammed drill bit, as excessive force can cause damage to the material or the drill itself. If you’re unsure or uncomfortable, it’s best to seek professional assistance.

Can I sharpen a dull drill bit?

Yes, you can sharpen a dull drill bit to restore its cutting abilities. One method is to use a bench grinder. Carefully position the bit at a 60-degree angle against the grinder’s wheel and rotate it in a counterclockwise motion. Be sure to maintain a consistent angle to ensure an even sharpening. Pause occasionally to dip the bit in water to prevent overheating. Another option is to use a drill bit sharpener, which simplifies the process. These sharpeners typically have guides and grinding wheels designed specifically for drill bits.

Keep in mind that excessive sharpening can shorten the overall lifespan of the bit. It’s also important to follow safety guidelines when working with power tools, such as wearing protective goggles and gloves.

What is the best drill bit for drilling through concrete?

When drilling through concrete, it’s crucial to use a drill bit specifically designed for the task. Masonry drill bits, made of carbide or diamond-tipped, are the best choice. The carbide bits are suitable for most concrete surfaces, while diamond-tipped bits offer enhanced durability and performance.

For optimal results, use a hammer drill along with the masonry drill bit. The hammering action helps break the concrete, while the rotation creates a hole. It’s important to apply steady pressure and avoid excessive force, as this can cause the bit to overheat or become damaged.

Can I drill through metal with a wood drill bit?

While wood drill bits are designed specifically for drilling through wood, they are not ideal for metal. Metal drill bits, also known as high-speed steel (HSS) bits, are specifically engineered to handle the hardness and toughness of metal surfaces. They have a sharper cutting edge and are more resistant to heat, ensuring efficient and precise drilling in metal.

Attempting to drill through metal with a wood drill bit can result in a slower, less effective drilling process, and may even damage the bit itself. It’s always best to use the appropriate drill bit for the material you are working with.

Can I use a drill bit with a different shank size?

In most cases, it is not recommended to use a drill bit with a significantly different shank size from what your drill is designed for. The shank diameter of the drill bit should match the chuck size of your drill to ensure a secure and stable fit. Using a drill bit with a smaller shank size can cause the bit to wobble or even slip out of the chuck during operation, resulting in potential injury or damage.

If you need to use a drill bit with a different shank size, you may consider using a chuck adapter to bridge the gap. However, it’s important to check the compatibility of the adapter with your drill and exercise caution during use.

Summary:

So, can you drill out a drill bit? The answer is no. When a drill bit gets dull or breaks, it’s best to replace it with a new one. Trying to drill out a drill bit can damage the tool and lead to ineffective drilling. It’s important to take care of your drill bits and use them properly to ensure they last longer and work efficiently.