Can you grind on a lathe? If you’ve ever wondered about this, you’re in the right place! In this article, we’ll explore the fascinating world of lathe grinding and answer your burning question. So, let’s dive in and uncover the secrets of grinding on a lathe together!

When it comes to machining, a lathe is a versatile tool that can perform various operations. But can you actually grind on a lathe? Well, the answer is both yes and no. While a lathe is primarily designed for turning and shaping materials, some lathes can also be equipped with grinding attachments that allow for limited grinding capabilities.

So, if you’re interested in learning more about grinding on a lathe, including the types of grinding operations you can perform and the considerations to keep in mind, keep reading! Whether you’re a hobbyist or a professional machinist, understanding the possibilities and limitations of grinding on a lathe can open up a whole new world of possibilities. Let’s get grinding!

Can You Grind on a Lathe? Exploring the Possibilities

When it comes to machining, one of the key tools in a workshop is a lathe. But can you grind on a lathe? This question often arises for those looking to expand their machining capabilities or optimize their processes. In this article, we will delve into the world of lathe grinding and explore the possibilities it offers. From the basics of grinding to the benefits and tips for getting started, we’ll cover everything you need to know to determine if grinding on a lathe is the right choice for you.

The Basics of Grinding on a Lathe

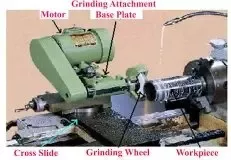

Grinding on a lathe involves using the lathe machine to remove material from a workpiece using an abrasive wheel or belt. While lathe machines are primarily used for turning operations, they can be adapted for grinding tasks by mounting a grinding attachment or tool post grinder. By affixing the grinding tool to the lathe, you can achieve precise grinding results while taking advantage of the lathe’s rotational capabilities.

Grinding on a lathe offers several advantages. Firstly, it eliminates the need for a separate grinding machine, saving space and cost. Additionally, the lathe’s ability to rotate the workpiece allows for more versatile grinding operations, such as cylindrical grinding, taper grinding, and internal grinding. This makes a lathe-grinding combo a versatile tool in a workshop where space and resources may be limited.

However, it’s important to note that grinding on a lathe requires proper setup, knowledge of grinding techniques, and suitable grinding tools. The precision and surface finish achieved may not be as high as those achieved with dedicated grinding machines. Nevertheless, with the right approach and techniques, grinding on a lathe can deliver satisfactory results for many applications.

Benefits of Grinding on a Lathe

Grinding on a lathe offers several benefits to machinists and workshops. Here are a few key advantages:

- Space and cost savings: Combining grinding capabilities with a lathe eliminates the need for a separate grinding machine, saving valuable workshop space and reducing costs.

- Versatility: A lathe can perform various turning operations, and with the addition of grinding capabilities, it can also handle grinding tasks like cylindrical grinding, taper grinding, and more.

- Streamlined workflow: With grinding capabilities on a lathe, machinists can complete multiple tasks without having to move the workpiece to a different machine, resulting in a streamlined workflow and increased productivity.

Tips for Grinding on a Lathe

While grinding on a lathe can be a valuable addition to your machining repertoire, it requires careful consideration and attention to detail. Here are some tips to help you get started:

- Choose the right grinding attachment: Depending on your specific grinding needs, select the appropriate grinding tool or attachment that is compatible with your lathe model.

- Ensure proper setup: Follow the manufacturer’s instructions for installing and aligning the grinding attachment or tool post grinder. A well-aligned setup is crucial for achieving accurate and consistent grinding results.

- Use the appropriate grinding technique: Different grinding tasks require specific techniques. Research and practice grinding techniques such as plunge grinding, traverse grinding, and profile grinding to maximize your efficiency and achieve desired results.

Exploring Advanced Grinding Techniques on a Lathe

Once you have familiarized yourself with the basics of grinding on a lathe, you may want to explore advanced grinding techniques that can further expand your capabilities. Here are three advanced techniques to consider:

1. Thread grinding: With the appropriate grinding attachment and techniques, you can use a lathe to grind threads on a workpiece, eliminating the need for thread-cutting tools.

2. Surface grinding: While not commonly done on a lathe, surface grinding with a lathe can be achieved by mounting a magnetic chuck to the lathe’s spindle and using a grinding wheel to remove material from the workpiece’s surface.

3. Centerless grinding: By utilizing a centerless grinding attachment, you can perform centerless grinding on a lathe, allowing for precise and efficient grinding of round workpieces without the need for center holes.

Conclusion

Grinding on a lathe opens up new possibilities and allows for more efficient utilization of resources in a machining workshop. By combining the turning and grinding capabilities of a lathe, you can save space and costs while achieving satisfactory grinding results. However, it’s important to keep in mind that grinding on a lathe requires properly chosen tools, appropriate setup, and knowledge of grinding techniques. By following best practices, you can harness the full potential of a lathe as a grinding tool and enhance your machining capabilities.

Key Takeaways: Can You Grind on a Lathe?

- Yes, grinding can be done on a lathe by using a tool called a grinding wheel.

- Grinding on a lathe is useful for shaping and finishing metal and other materials.

- It is important to use the correct grinding wheel and techniques to ensure safety and effectiveness.

- Grinding on a lathe requires proper setup and adjustment to achieve desired results.

- Consulting with an experienced professional is recommended for beginners to learn proper grinding techniques.

Frequently Asked Questions

Here are some common questions about grinding on a lathe:

1. Can you use a lathe for grinding purposes?

Yes, it’s possible to use a lathe for grinding tasks, although it’s not its primary function. Lathes are typically used for shaping and turning materials, such as wood or metal. However, with the right attachments and tools, you can repurpose a lathe for grinding. It’s important to ensure that the lathe is equipped with a grinding wheel and the necessary safety precautions are in place.

Keep in mind that while a lathe can be adapted for grinding, it may not provide the same precision or speed as a dedicated grinding machine. Grinding on a lathe is more suitable for small and simple grinding tasks, rather than heavy-duty or complex projects.

2. What are the benefits of using a lathe for grinding?

Using a lathe for grinding offers a few advantages. Firstly, if you already have a lathe in your workshop, repurposing it for grinding tasks can save you money and space compared to purchasing a separate grinding machine.

Additionally, a lathe provides good stability and control, which can be beneficial when grinding small or delicate workpieces. The ability to adjust the speed and feed rate on a lathe allows for more precise grinding. It also allows you to use different types of grinding attachments, expanding the versatility of your lathe.

3. What safety precautions should I take when grinding on a lathe?

When grinding on a lathe, it’s crucial to prioritize safety. Start by wearing appropriate personal protective equipment, such as safety goggles, gloves, and a dust mask. Ensure that the lathe is securely mounted and stable before proceeding.

Make sure the grinding wheel is compatible with the lathe and properly installed. Check the speed of the lathe to ensure it matches the recommended speed for the grinding wheel being used. Always keep your hands and fingers a safe distance away from the rotating components to avoid accidents.

4. What types of grinding tasks are suitable for a lathe?

A lathe can handle various grinding tasks, including sharpening tools, smoothing or polishing metal edges, removing small amounts of material, and grinding cylindrical shapes or contours. It’s best suited for small-scale grinding projects that require precision and control, rather than heavy material removal or complex shapes.

Common applications for grinding on a lathe include sharpening lathe tools, grinding drill bits, deburring metal workpieces, and creating smooth finishes on cylindrical or curved surfaces.

5. Are there any limitations to grinding on a lathe?

While a lathe can be adapted for grinding, there are some limitations to consider. Since a lathe is primarily designed for shaping and turning, it may not provide the same level of precision and speed as a dedicated grinding machine.

In addition, grinding on a lathe is more suitable for smaller and simpler grinding tasks. If you need to remove a significant amount of material or work on complex shapes, it’s advisable to use a dedicated grinding machine or seek alternative methods.

Toolpost Grinder Part 24: First Test Grind

Summary

Can you grind on a lathe? Grinders and lathes have different purposes. A grinder is used for sharpening and smoothing while a lathe shapes and turns objects. Trying to grind on a lathe can be dangerous and damage both the lathe and the object being worked on. It’s best to use each tool for its intended purpose.

In conclusion , remember to use the right tool for the job. Grinders and lathes serve different functions, so avoid grinding on a lathe to prevent accidents and protect your equipment. Stick to safety guidelines and enjoy the benefits of using each tool correctly.