Welcome, young engineering enthusiasts! Have you ever wondered if you can lathe hardened steel? Well, you’ve come to the right place. In this article, we’ll dive into the fascinating world of machining and explore whether lathing hardened steel is possible.

Whether you’re tinkering in your own mini-workshop or dreaming of becoming a skilled machinist, understanding the capabilities of your lathe machine is crucial. But before we dig deeper, let’s start by answering the burning question on your mind: Can you lathe hardened steel?

When it comes to machining hardened steel, there are some challenges to overcome. Join us as we uncover the techniques, tools, and tricks that can help you turn the seemingly impossible into a reality. So strap on your safety goggles and get ready for a thrilling adventure in the realm of lathing hardened steel. Let’s dive in!

Wondering if you can lathe hardened steel? Absolutely! Lathe machines equipped with the right tools and techniques can handle hardened steel with precision. By using high-quality carbide cutting tools and lubricant, you can effectively turn, shape, and polish hardened steel on a lathe. Ensure the lathe is properly set up with appropriate speeds and feeds for optimal results. So go ahead and tackle your hardened steel projects with confidence!

Can You Lathe Hardened Steel?

When it comes to machining hardened steel, many people wonder if it can be done on a lathe. Hardened steel is notoriously difficult to work with due to its high hardness and abrasiveness. However, with the right tools, techniques, and expertise, it is indeed possible to lathe hardened steel. In this article, we will explore the process of lathing hardened steel, the challenges involved, and the best practices to achieve successful results.

Understanding Hardened Steel

Hardened steel is steel that has undergone a heat treatment process called quenching and tempering, which increases its hardness and strength. This process involves heating the steel to a high temperature and then rapidly cooling it in a quenching medium, such as oil or water. The rapid cooling traps the carbon and other elements in the steel, creating a hard and durable material.

Hardened steel typically has a hardness of 40-70 HRC (Rockwell hardness scale). It is used in various applications where high strength and wear resistance are required, such as cutting tools, bearings, gears, and dies. Due to its hardness, machining hardened steel can be challenging and requires specialized tools and techniques.

Tools for Lathing Hardened Steel

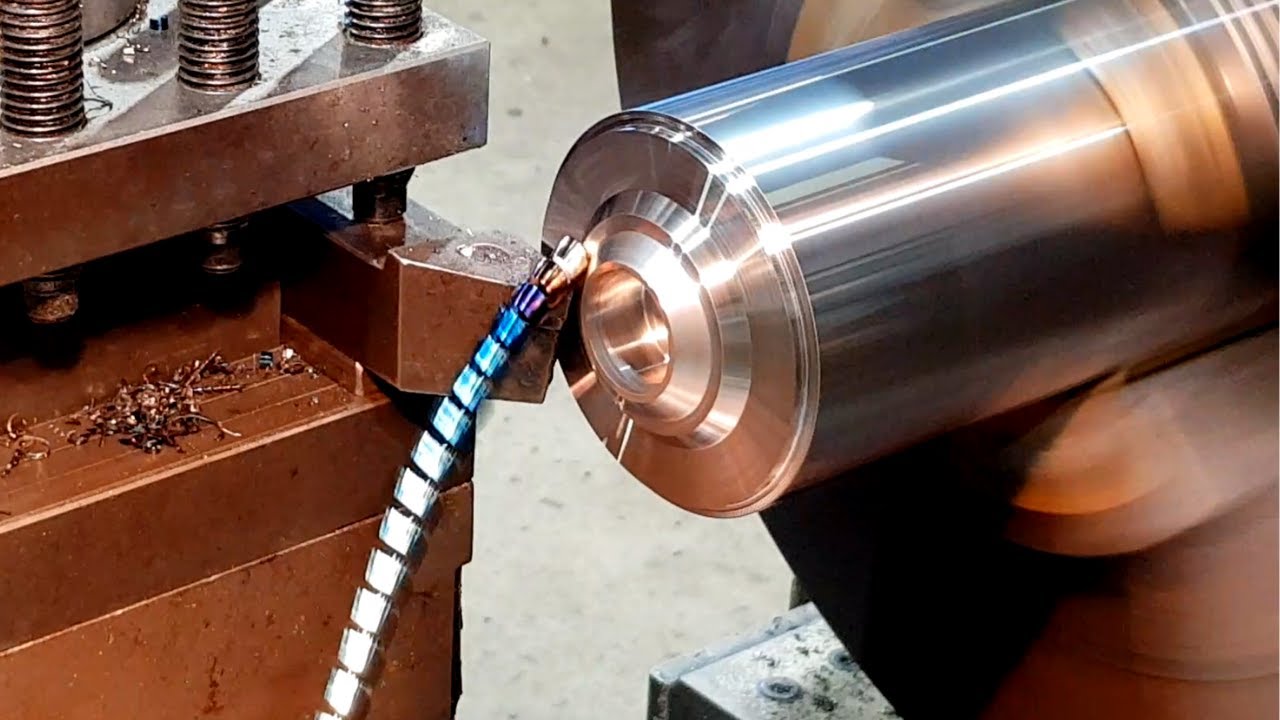

When lathing hardened steel, using the right tools is crucial for success. The following are some of the essential tools and equipment for machining hardened steel on a lathe:

- Carbide Inserts: Carbide inserts are made from a combination of tungsten carbide and a binding metal, such as cobalt. They are extremely hard and durable, making them ideal for cutting hardened steel.

- Diamond-Tipped Tooling: Diamond tools are known for their exceptional hardness and wear resistance. They can be used for precise and efficient cutting of hardened steel.

- Cutting Fluid: Using a cutting fluid is essential when lathing hardened steel. It helps to lubricate the cutting tool and workpiece, reducing friction and heat, and prolonging tool life.

- Lathe with High Torque: Machining hardened steel requires a lathe with sufficient power and torque to withstand the high cutting forces involved.

Techniques for Lathing Hardened Steel

Successful machining of hardened steel on a lathe requires implementing specific techniques. Here are some key techniques to keep in mind:

- Slow Speeds: Hardened steel should be machined at low speeds to prevent overheating and tool wear. High speeds can cause the cutting tool to wear out quickly and reduce the surface quality of the workpiece.

- Steady Feeds: Consistent and steady feeds are essential for achieving precise cuts and preventing chatter or vibrations. Too fast or uneven feeds can result in tool breakage and poor surface finish.

- Depth of Cut: When lathing hardened steel, it is advisable to take smaller depth of cuts to avoid putting excessive stress on the cutting tool and reducing the risk of deflection.

- Cooling and Lubrication: Proper cooling and lubrication are crucial when machining hardened steel. Using cutting fluids or coolants helps dissipate heat generated during the cutting process, reducing tool wear and improving surface finish.

Benefits of Lathing Hardened Steel

Lathing hardened steel comes with several benefits, including:

- Cost Savings: By being able to machine hardened steel on a lathe, manufacturers can save on costs by eliminating the need for specialized grinding equipment or outsourcing the machining process.

- Flexibility: Owning the capabilities to lathe hardened steel offers flexibility in design modifications, repairs, or modifications of hardened steel components without the need for complete replacement.

- Precision: Lathing allows for precise machining of hardened steel, ensuring tight tolerances and high-quality surface finishes.

Can You Lathe Hardened Steel? – Tips and Best Practices

When attempting to lathe hardened steel, there are some tips and best practices that can improve your chances of success:

1. Choose the Right Tooling

Invest in high-quality carbide or diamond-tipped tooling specifically designed for machining hardened steel. Using the right tooling will ensure better cutting performance and prolonged tool life.

2. Optimize Speeds and Feeds

Experiment with different speeds and feeds to find the optimal parameters. Start with conservative settings and gradually increase them while monitoring tool wear and surface finish.

3. Use Cutting Fluids

Apply cutting fluids or coolants generously to the cutting tool and workpiece. This helps dissipate heat, reduce friction, and improve surface finish.

Can You Lathe Hardened Steel? – Common Challenges

While lathing hardened steel can be done, it is not without its challenges. Some common challenges include:

1. Tool Wear

Hardened steel is highly abrasive and can cause rapid tool wear. Choosing the right tooling and optimizing cutting parameters can help mitigate this issue.

2. Heat Generation

Working with hardened steel generates a significant amount of heat, leading to tool and workpiece damage. Proper cooling and lubrication, along with conservative cutting parameters, can help manage heat generation.

3. Surface Finish

Obtaining a smooth surface finish on hardened steel can be challenging. Experimenting with different cutting parameters, using sharp tools, and implementing proper cooling and lubrication can help achieve better results.

Can You Lathe Hardened Steel? – Conclusion

While lathing hardened steel presents unique challenges, it is indeed possible with the right tools, techniques, and expertise. By choosing the appropriate tooling, optimizing speeds and feeds, and implementing proper cooling and lubrication, you can successfully lathe hardened steel and achieve high-quality results. Remember to take your time, monitor tool wear, and make adjustments as necessary. With practice and patience, you can become proficient in machining hardened steel on a lathe.

Key Takeaways: Can You Lathe Hardened Steel?

- Lathe can be used to machine hardened steel, but special precautions need to be taken.

- Using carbide tooling is essential for lathe turning hardened steel.

- Slower cutting speeds and a lubricant are required to prevent heat buildup and maintain tool life.

- Hardened steel should be preheated to reduce its hardness before machining.

- Constant monitoring and frequent tool changes may be necessary when lathe turning hardened steel.

Frequently Asked Questions

Are you curious about whether or not you can lathe hardened steel? Check out these commonly asked questions and find out more!

1. Is it possible to lathe hardened steel?

Yes, it is possible to lathe hardened steel, although it can be a challenging process. Hardened steel is extremely tough and can cause excessive tool wear, leading to difficulties in machining. However, with the right tools, techniques, and expertise, it is possible to lathe hardened steel.

One effective method is to use carbide or ceramic inserts specifically designed for machining hardened steel. These inserts are more resistant to wear and can provide the necessary cutting force to remove material from hardened steel. Additionally, lubrication and coolant are crucial in reducing both heat and tool wear during the lathe process.

2. What factors should I consider when lathe-turning hardened steel?

When lathe-turning hardened steel, there are several factors to consider. First and foremost, you need to make sure you have the appropriate cutting tools and inserts designed for machining hardened steel. Carbide or ceramic inserts with a high hardness and abrasion resistance are recommended.

Additionally, the cutting speed should be carefully calculated to avoid excessive heat generation. A lower cutting speed is generally preferred when working with hardened steel to prevent overheating and tool wear. Finally, using the correct feed rate and depth of cut is important to ensure a smooth and efficient turning process without straining the tools.

3. What safety precautions should I take when lathe-turning hardened steel?

When lathe-turning hardened steel, it is important to prioritize safety. Make sure to wear appropriate personal protective equipment (PPE), including safety glasses or goggles, gloves, and a dust mask if necessary. This will protect you from any flying chips, coolant splashes, or potential exposure to fine particles.

Keep the lathe area clean and free of clutter to prevent tripping hazards and ensure a clear workspace. Additionally, be mindful of the cutting tools and chips, as they can be sharp and cause injuries. Always exercise caution and follow proper machining techniques to minimize the risk of accidents.

4. Can I use my regular lathe for machining hardened steel?

Using a regular lathe for machining hardened steel is not recommended. Hardened steel is much harder than regular steel and can quickly wear down standard tooling. To effectively machine hardened steel, it is necessary to use specialized tool inserts made from materials such as carbide or ceramic, which are designed to withstand the hardness of the material.

If you frequently work with hardened steel, it may be worth considering investing in a dedicated lathe with the necessary features and capabilities for machining this type of material. This will ensure better results and prolong the lifespan of your tools.

5. What are some alternative methods to lathe-turning hardened steel?

If you are unable to lathe-turn hardened steel or want to explore alternative methods, there are a few options available. One common alternative is grinding, where a grinding wheel or abrasive tool is used to remove material from the hardened steel. This method allows for precision and control but requires specialized equipment.

Another option is electrical discharge machining (EDM), which uses electrical sparks to erode the hardened steel. EDM can achieve intricate shapes and does not rely on cutting tools or inserts. However, it may not be suitable for all applications and is generally slower than lathe-turning or grinding.

Summary

So, can you lathe hardened steel? In short, it’s difficult but not impossible. You’ll need the right tools and techniques, like using high-quality carbide tools and slow speeds. Keep in mind, though, that it may cause damage to your lathe in the long run. It’s best to consult with a professional if you’re unsure.

Remember, safety is crucial when working with machinery, so always wear protective gear. And most importantly, don’t forget to practice and improve your skills because becoming a skilled machinist takes time and patience.