So you’re curious about whether you can make gears on a lathe? Well, my friend, you’ve come to the right place! Gears are fascinating mechanisms that play a vital role in many machines, from bicycles to automobiles. In this article, we’ll explore the exciting world of gear-making using a lathe.

Now, you might be wondering, what exactly is a lathe? Picture this: a lathe is like a magician’s workshop, where a spinning workpiece is carefully shaped and sculpted by the skilled hands of the operator. But here’s where it gets even more interesting. Can you believe that with the right tools and techniques, you can transform a simple piece of metal into a perfectly functioning gear?

Of course, the answer is a resounding “Yes!” With the right knowledge, patience, and a trusty lathe, you can embark on a gear-making adventure that will leave you amazed. So, strap in, my curious friend, and let’s dive into the wonderful world of making gears on a lathe!

- Start by selecting the appropriate material for your gears.

- Mount the material securely on the lathe using a chuck or a faceplate.

- Set the gear cutting tool on the lathe toolpost.

- Adjust the depth of cut and feed rate according to your gear specifications.

- Turn on the lathe and carefully guide the cutting tool along the gear profile.

- Continue cutting until the desired gear is formed.

Note: Always follow proper safety precautions while working with a lathe.

Can You Make Gears on a Lathe? A Comprehensive Guide

Lathe machines are primarily used for turning, facing, and drilling operations, but can they also be used to make gears? In this article, we will explore the feasibility and process of making gears on a lathe. We will delve into the necessary tools, techniques, and challenges involved in gear-making on a lathe machine.

The Basics of Gear-Making on a Lathe

Before we dive into the details of making gears on a lathe, it is important to understand the basics of gear manufacturing. Gears are mechanical devices with teeth that mesh together to transmit motion and power. They come in various shapes, sizes, and configurations, depending on the specific application. The gear-making process involves complex calculations and precision machining to ensure optimal performance.

The Feasibility of Making Gears on a Lathe

While lathes are not typically designed for gear-making, it is indeed possible to produce gears using lathe machines. However, it is important to note that lathes are best suited for creating simple gears with fewer teeth, rather than intricate gears with complex tooth profiles. The feasibility of making gears on a lathe depends on factors such as the size of the gear, its tooth count, the materials involved, and the desired level of precision.

For small-scale projects or hobbyist applications, making gears on a lathe can be a cost-effective and accessible solution. However, for industrial or high-precision gears, specialized gear-cutting machines such as hobbing or gear shaping machines are typically used. These machines offer enhanced precision and efficiency, making them better suited for large-scale gear production.

The Gear-Making Process on a Lathe

Making gears on a lathe involves several steps and specialized tools. Here is a simplified overview of the gear-making process on a lathe:

- Select the Gear Blank: Choose a suitable piece of material to serve as the base for the gear.

- Mount the Gear Blank: Secure the gear blank on the lathe machine using appropriate fixturing methods.

- Calculate Gear Specifications: Determine the desired tooth count, pitch, diametral pitch, and other specifications based on the gear’s intended use.

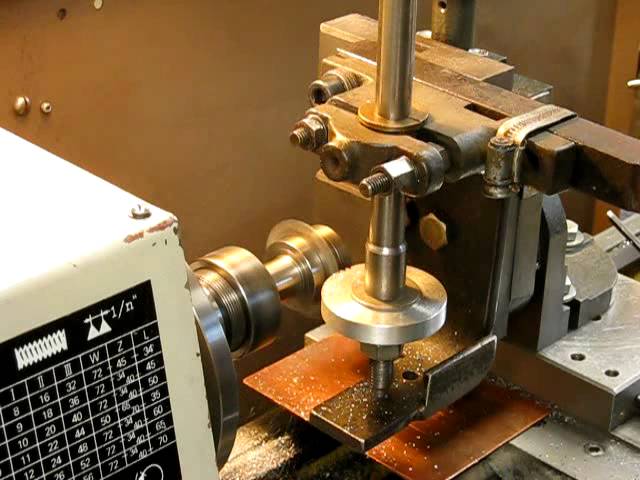

- Set Up the Gear Cutting Tool: Install the gear cutting tool, such as a gear hob or gear shaping cutter, on the lathe’s toolpost.

- Configure the Lathe: Adjust the lathe’s speed, feed rate, and other parameters for optimal gear cutting.

- Cut the Gear Teeth: Use the gear cutting tool to gradually shape the gear teeth according to the calculated specifications.

- Finish and Inspect: Employ additional machining and finishing techniques, such as deburring and polishing, to ensure the gear meets the required standards. Perform a thorough inspection to verify the accuracy of the gear’s tooth profile.

It is important to note that making gears on a lathe requires expertise and experience. Precision measurements, tool selection, and proper technique are crucial for achieving accurate gear profiles. Additionally, it is recommended to refer to gear-making guides, tutorials, or consult experienced machinists for guidance in gear-making projects.

Tips for Successful Gear-Making on a Lathe

Now that we have explored the basics of making gears on a lathe, let’s delve into some tips to ensure successful gear manufacturing:

1. Choose the Right Material:

Select a material suitable for the intended application of the gear. Consider factors such as strength, wear resistance, and compatibility with the mating gears.

2. Optimize Tool Selection:

Invest in high-quality gear cutting tools that are specifically designed for lathe-based gear manufacturing. The right tool geometry and material will ensure accurate and efficient gear cutting.

3. Implement Proper Cutting Techniques:

Use appropriate cutting techniques, such as single-point gear cutting or gear hobbing, to achieve the desired tooth geometry. Pay attention to tool feed rate, depth of cut, and overall cutting strategy.

4. Perform Regular Maintenance:

Maintain your lathe machine and cutting tools regularly to ensure optimal performance. Proper lubrication, tool sharpening, and machine calibration are essential for consistent and precise gear-making.

5. Seek Professional Guidance:

If you are new to gear-making or tackling a complex gear project, don’t hesitate to seek advice from experienced machinists or gear manufacturing experts. They can provide valuable insights and guidance to ensure your gear manufacturing endeavors are successful.

Conclusion

Making gears on a lathe is indeed feasible, especially for small-scale or hobbyist projects. However, it is important to consider the limitations of lathe-based gear manufacturing and the complexity of the gear required. It is always recommended to consult experts, refer to gear-making resources, and invest in the proper tools and techniques to achieve accurate and reliable results. With the right knowledge and approach, you can embark on gear-making projects with confidence and precision.

Can You Make Gears on a Lathe? Just How Easy Is It?

- Yes, you can make gears on a lathe!

- Using proper techniques and tools, gears can be machined on a lathe.

- Having a lathe with a gear-cutting attachment makes the process easier.

- It requires knowledge of gear calculations and precision machining skills.

- With patience and practice, anyone can learn to make gears on a lathe.

Frequently Asked Questions

Welcome to our frequently asked questions section about making gears on a lathe. If you’re interested in creating gears yourself, you’ve come to the right place. Read on to find answers to some common questions on this topic.

1. How can I make gears on a lathe?

Making gears on a lathe is indeed possible and can be a fascinating process. To make gears, you’ll need a lathe equipped with certain gear-cutting attachments. These attachments allow you to cut teeth into a blank gear, transforming it into the desired shape. It’s important to have a good understanding of the gear profile, module, and cutter angles to achieve precise results.

Once you have the necessary attachments and tools, you can begin by securely mounting your gear blank onto the lathe. Then, using the lathe’s gear-cutting attachment, you’ll gradually cut the teeth into the blank while rotating it. The rotation speed, feed rate, and depth of cut will depend on the type and size of the gear you’re making. It’s crucial to follow safety protocols and take your time to ensure accuracy.

2. What materials can be used to make gears on a lathe?

When making gears on a lathe, you have various material options to choose from based on your needs and preferences. Common materials for gear-making include brass, steel, aluminum, and even plastic. Each material has its own advantages and considerations.

Brass is a popular choice due to its machinability and resistance to corrosion, making it suitable for many applications. Steel gears offer excellent strength and durability, making them ideal for heavy-duty applications. Aluminum is lightweight and can be useful in applications where weight reduction is a priority. Plastic gears are often chosen when cost-effectiveness and noise reduction are primary concerns.

3. Can a lathe make any type of gear?

A lathe can indeed make many types of gears. However, the specific type of gear you can make will depend on your lathe’s capabilities and the gear-cutting attachments you have. A lathe is commonly used for making spur gears, which have teeth parallel to the gear’s axis.

Other gear types, such as helical gears, bevel gears, and worm gears, may require specialized equipment or processes beyond a traditional lathe. It’s essential to consider your project requirements and consult experts or utilize additional machinery if needed.

4. Are there any limitations to making gears on a lathe?

While making gears on a lathe is possible, there are certain limitations to be aware of. The size of the gears you can make on a lathe is determined by the swing and distance between centers of your lathe. Larger gears may require a bigger lathe or alternative methods. Additionally, the accuracy of the teeth profile can be influenced by the precision and condition of your lathe and gear-cutting attachments.

It’s worth noting that gear-making on a lathe can be time-consuming and may require skilled craftsmanship. Depending on your project’s complexity, you may need to invest in dedicated gear-making equipment for better efficiency and accuracy.

5. Where can I learn more about making gears on a lathe?

If you’re interested in delving deeper into the world of making gears on a lathe, there are several resources available to expand your knowledge. Consider exploring online tutorials, books, or even attending workshops or classes. Joining communities, forums, or clubs centered around machining and gear-making can also provide valuable insights and opportunities to connect with experienced individuals who can share their expertise.

Keep in mind that practice and experimentation are essential when honing your gear-making skills. Embrace the learning process, be patient, and don’t hesitate to seek guidance from experts in this field.

Summary

You can make gears on a lathe by using a dividing head or a gear cutting attachment. A dividing head helps you accurately divide the gear’s circumference into equal parts, while a gear cutting attachment allows you to cut teeth on the gear. Both methods require careful measurement and calculation to ensure the gear fits and functions correctly.

When making gears on a lathe, it’s important to choose the right tools and materials, and to follow the correct steps for setup and operation. Remember to take your time, measure accurately, and always prioritize safety. With patience and practice, you can create functional gears on a lathe for your various projects. So go ahead and give it a try!