Can you mill with a lathe? If you’ve ever wondered about this intriguing question, you’re in the right place. In this article, we’ll explore the possibilities of using a lathe for milling. So, grab your curiosity and let’s dive into the world of machining!

Now, you may be thinking, “Wait a minute, isn’t a lathe meant for turning cylindrical objects?” Well, that’s true, but it turns out a lathe can do more than just turning. It has the potential to become a versatile milling machine as well! How cool is that?

So, if you’ve ever wondered whether you can mill with a lathe and want to unlock its milling potential, stick around. We’ll uncover the secrets, explore the techniques, and guide you through the world of lathe milling. Are you ready to embark on this exciting machining adventure? Let’s get started!

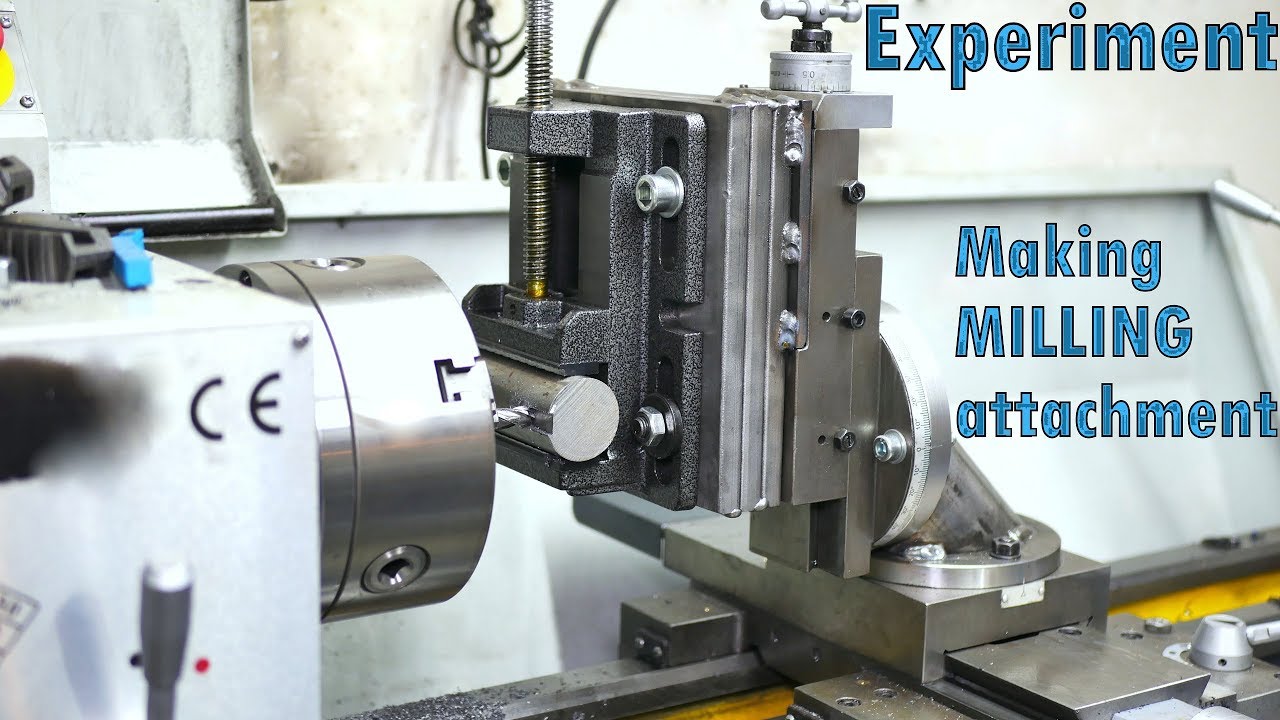

While a lathe is primarily designed for turning operations, it is possible to use a lathe for milling tasks with the right setup and attachments. By mounting a milling attachment on the lathe’s cross slide, you can perform limited milling operations such as slotting, grooving, and drilling. However, it’s important to note that a lathe is not designed for heavy-duty milling and may have limitations in terms of precision and versatility compared to a dedicated milling machine.

Can You Mill with a Lathe?

When it comes to machining operations, the terms “milling” and “turning” are often used interchangeably. However, there are distinct differences between the two. While milling involves the removal of material by rotating a cutting tool, turning refers to the process of shaping a workpiece by rotating it against a stationary cutting tool. So, can you mill with a lathe? Let’s explore this question in detail.

The Anatomy of a Lathe

Before delving into whether milling can be done with a lathe, it’s crucial to understand the components of a lathe. A typical lathe consists of a bed, headstock, tailstock, carriage, and a tool post. The workpiece is held securely in the chuck or collet, and the rotating spindle provides the necessary rotational motion. The cutting tool, mounted on the tool post, is positioned and guided by the carriage.

Can a Lathe Perform Milling Operations?

While a lathe is primarily used for turning operations, it can also be adapted to perform certain milling tasks. This is made possible by attaching a milling attachment or a vertical slide to the lathe’s cross-slide. With this setup, the lathe can be used to perform limited milling operations, such as slotting, grooving, and keyway cutting.

However, it’s important to note that the milling capabilities of a lathe are limited compared to a dedicated milling machine. The lathe’s design and features are optimized for turning, and its rigidity and horsepower may not be suitable for heavy-duty milling tasks. So, while a lathe can be used for milling in certain scenarios, it is generally recommended to use a milling machine for more complex milling operations.

Benefits and Limitations of Milling with a Lathe

The use of a lathe for milling tasks has its advantages and limitations. One of the key benefits is cost-effectiveness. Investing in a milling attachment for a lathe is often more affordable than purchasing a dedicated milling machine. Additionally, if space is limited, using a lathe for milling operations saves valuable workspace.

However, it’s essential to consider the limitations of milling with a lathe. As mentioned earlier, the rigidity and horsepower of a lathe may not be sufficient for heavy-duty milling. The precision and accuracy achieved with a lathe may also not match that of a milling machine. Therefore, when precise milling operations are required, it is best to use a milling machine for optimal results.

Tips for Milling with a Lathe

If you decide to use a lathe for milling tasks, here are some tips to ensure successful results:

- Choose the right cutting tools: Select cutting tools suitable for milling and ensure they are securely mounted.

- Take small cuts: Due to the lathe’s limitations, it’s advisable to take smaller cuts to prevent overloading the machine.

- Monitor the machine’s performance: Keep a close eye on the lathe’s performance, including vibrations and unusual noises, and make necessary adjustments.

- Secure the workpiece: Use appropriate fixtures and ensure the workpiece is securely held to avoid any movement during milling operations.

- Make multiple passes: When milling with a lathe, it’s often more effective to make multiple passes rather than trying to remove a large amount of material at once.

Conclusion

While a lathe can be used for limited milling operations, it is important to understand its limitations and consider using a milling machine for more complex milling tasks. By utilizing a lathe for milling, you can take advantage of its cost-effectiveness and space-saving benefits. However, for precision milling operations, a dedicated milling machine is the recommended choice.

Key Takeaways: Can You Mill with a Lathe?

- Milling with a lathe is possible, but it is not the primary function of a lathe.

- A lathe can perform basic milling tasks, such as cutting flat surfaces, slots, and keyways.

- For more complex milling operations, a dedicated milling machine is usually preferred.

- Using a lathe for milling requires additional tooling and setup adjustments.

- If you need to do milling frequently, investing in a milling machine is recommended.

Frequently Asked Questions

Below are some commonly asked questions about milling with a lathe and their answers.

1. Can you use a lathe to mill materials?

While a lathe is primarily used for turning cylindrical objects, it is possible to do some milling tasks with the right setup. One method is called “milling on the lathe,” where a milling attachment or a tool holder is used along with milling cutters. However, it’s important to note that a lathe is not designed for heavy milling work, and the results may not be as precise as using a dedicated milling machine.

If you only need to perform occasional milling work or have limited space, using a lathe for light milling tasks can be a viable option. However, for more complex or heavy-duty milling projects, it’s recommended to use a milling machine for better accuracy and efficiency.

2. What are the limitations of milling with a lathe?

When using a lathe for milling, there are certain limitations to consider. Firstly, the size and weight of the workpiece can be a limiting factor, as a lathe usually has a smaller work envelope compared to a milling machine. Additionally, a lathe may not have the necessary rigidity and power required for heavy milling operations.

Furthermore, a lathe is intended for rotational cutting, so it may not provide the same level of accuracy and precision as a milling machine, especially for intricate or complex milling operations. It’s important to assess the specific requirements of your milling project and determine whether a lathe can meet them adequately.

3. What safety precautions should be taken when milling on a lathe?

When using a lathe for milling, it’s crucial to follow proper safety precautions. Firstly, ensure that the lathe is securely anchored to minimize vibrations during the milling process. Always wear appropriate personal protective equipment, such as safety glasses and ear protection, to safeguard against potential hazards.

Before starting the milling operation, make sure you have a clear plan and understand the sequence of steps involved. Take your time to set up the workpiece securely and position the milling attachment correctly. Always use the appropriate cutting tools and ensure they are properly secured.

4. What are the advantages of using a dedicated milling machine over a lathe for milling?

A dedicated milling machine offers several advantages over using a lathe for milling. Firstly, milling machines are designed specifically for milling tasks, providing greater precision, stability, and power. They have a wider range of tools and cutting options, allowing for more versatility in machining operations.

Milling machines also have larger work envelopes, enabling them to handle bigger and more complex workpieces. Additionally, they typically offer features such as adjustable speed control and automated tool changing, enhancing efficiency and productivity. If you frequently perform milling work or require high-precision milling, investing in a dedicated milling machine is recommended.

5. Can a lathe be converted into a milling machine?

While it’s technically possible to convert a lathe into a milling machine using specific attachments or modifications, it is generally not advisable. Converting a lathe into a milling machine requires considerable expertise and careful engineering to ensure safety, precision, and functionality.

It’s important to note that even with conversions, a lathe’s inherent limitations, such as rigidity and power, may still affect the quality and accuracy of milling operations. If you require the capabilities of a milling machine, it’s better to invest in a purpose-built milling machine rather than attempting to convert a lathe.

Summary

So, can you mill with a lathe? The answer is yes, but there are limitations. While a lathe primarily rotates the workpiece, it can be used for some milling tasks by attaching a milling attachment. However, it is important to note that a lathe is not designed for heavy milling work or complex operations.

Using a lathe for milling purposes can be a convenient solution for small projects and simple milling tasks. It can save you space and money compared to investing in a separate milling machine. However, if you need to do more extensive milling work or require precise and intricate designs, it is best to invest in a dedicated milling machine for better accuracy and efficiency.

In conclusion, while a lathe can be used for milling, its capabilities are limited, and it is not a substitute for a dedicated milling machine.