Do you enjoy working with power tools? Have you ever wondered if there is such a thing as over tightening a bandsaw blade? Well, you’re in the right place! In this article, we’ll explore the answer to the question, “Can you over tighten a bandsaw blade?” So let’s dive right in and discover the fascinating world of bandsaw maintenance!

When it comes to bandsaws, knowing the proper tension for the blade is crucial. But can you go overboard with tightening? That’s what we’re here to find out! We’ll discuss the potential risks of over tightening a bandsaw blade, as well as the right way to achieve the perfect tension. So, buckle up and get ready for an informative and exciting ride!

Whether you’re a beginner or an experienced woodworker, understanding the limits of bandsaw blade tension is essential. So, let’s get started and unravel the mysteries behind bandsaw blade tightening. Get ready to acquire some valuable knowledge and become a bandsaw expert in no time!

When it comes to bandsaw blades, it is possible to over tighten them. Over tightening can lead to higher stress on the blade, which can result in premature wear, breakage, or even damage to the bandsaw itself. It’s important to find the right balance when tightening your bandsaw blade to ensure proper tension without overdoing it. Follow the manufacturer’s recommendations and make small adjustments to achieve the optimal tension for your bandsaw blade.

Can You Over Tighten a Bandsaw Blade?

In the world of woodworking, a bandsaw is an essential tool for cutting curves and intricate shapes. However, when it comes to using a bandsaw, there are a few important factors to consider, including the tension of the blade. One common question that arises is whether it is possible to over tighten a bandsaw blade. In this article, we will delve into this topic and provide you with detailed information about the potential risks, consequences, and best practices when it comes to tensioning a bandsaw blade.

The Importance of Proper Blade Tension

Before diving into the question of whether you can over tighten a bandsaw blade, it is crucial to understand the importance of proper blade tension. Blade tension refers to the amount of force applied to the blade to keep it running straight and cutting accurately. Insufficient tension can result in poor cutting performance, blade drift, and increased risk of accidents. On the other hand, excessive tension can lead to blade breakage, premature wear, and even machine damage. Therefore, finding the right balance of tension is crucial for optimal bandsaw performance.

Understanding the Risks of Over Tightening

While it is important to tension a bandsaw blade adequately, over tightening can pose risks that can negatively impact both the bandsaw and the blade. Over tightening can lead to excessive stress on the blade, causing premature fatigue and increased likelihood of breakage. It can also put strain on the bandsaw’s internal components, such as the bearings and guides, potentially leading to accelerated wear and reduced machine lifespan. Additionally, over tightening can result in distorted or damaged blades, affecting the quality of cuts and increasing the chances of accidents. Therefore, it is crucial to be aware of the risks associated with over tightening and take necessary precautions to avoid them.

So, how do you know if your bandsaw blade is properly tensioned? The best way is to consult the manufacturer’s guidelines or refer to the bandsaw’s manual. These resources typically provide recommendations for the appropriate tension for different blade widths and materials. Additionally, you can also use the “blade deflection” test, where you lightly tap the blade with your finger to observe the amount it moves. If the blade deflects too much or hardly at all, it may indicate improper tensioning. By following these guidelines and performing regular maintenance on your bandsaw, you can ensure optimal performance and avoid the risks associated with over tightening the blade.

Common Mistakes to Avoid

While we’ve discussed the risks of over tightening a bandsaw blade, it’s also important to be aware of other common mistakes that users often make when it comes to blade tensioning. Let’s take a look at some of these mistakes and how to avoid them:

Not Checking Tension Regularly

One common mistake is not checking the blade tension regularly. As blades can lose tension over time due to stretching or changes in temperature, it is essential to periodically check and adjust the tension to maintain optimal performance.

Using the Wrong Blade Width or Type

Another mistake is using the wrong blade width or type for a particular application. Each blade has its own recommended tension range, and using a blade that is too wide or too narrow for the bandsaw’s specifications can lead to tensioning issues and subpar results.

Ignoring Signs of Blade Fatigue

Blade fatigue can occur over time due to continuous use and may result in a loss of tension. Ignoring signs of blade fatigue, such as frequent blade changes or reduced cutting performance, can lead to inaccurate cuts and potential safety hazards.

Proper Tensioning Techniques

To ensure you are tensioning your bandsaw blade correctly and avoiding both under and over tightening, here are some essential tips:

Refer to the Manufacturer’s Guidelines

The manufacturer’s guidelines are the most reliable source of information for recommended tension settings for your specific bandsaw model. They provide precise instructions based on the blade width, material, and other factors.

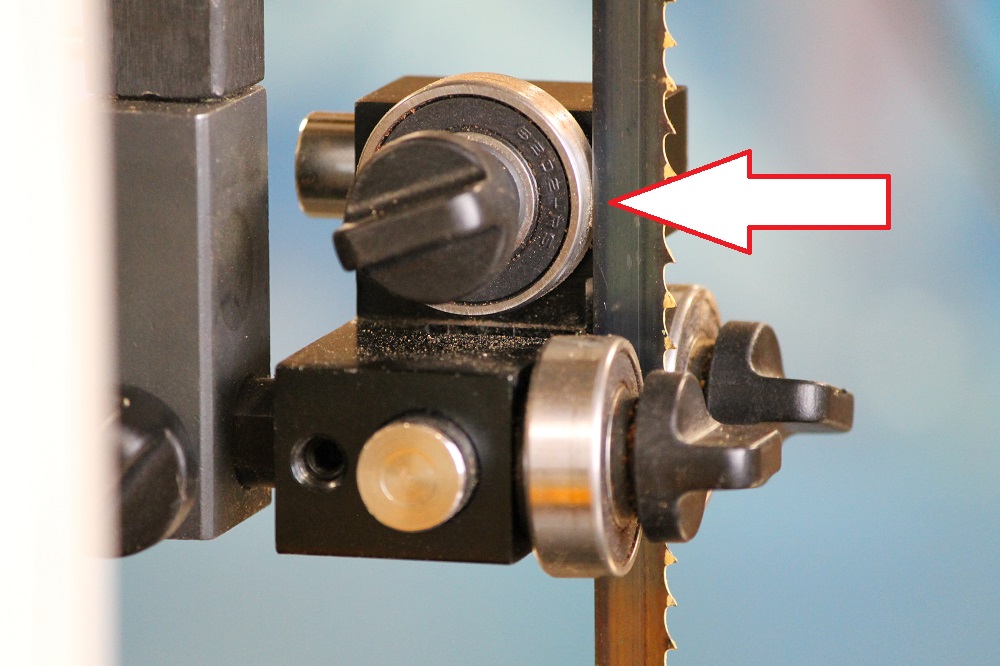

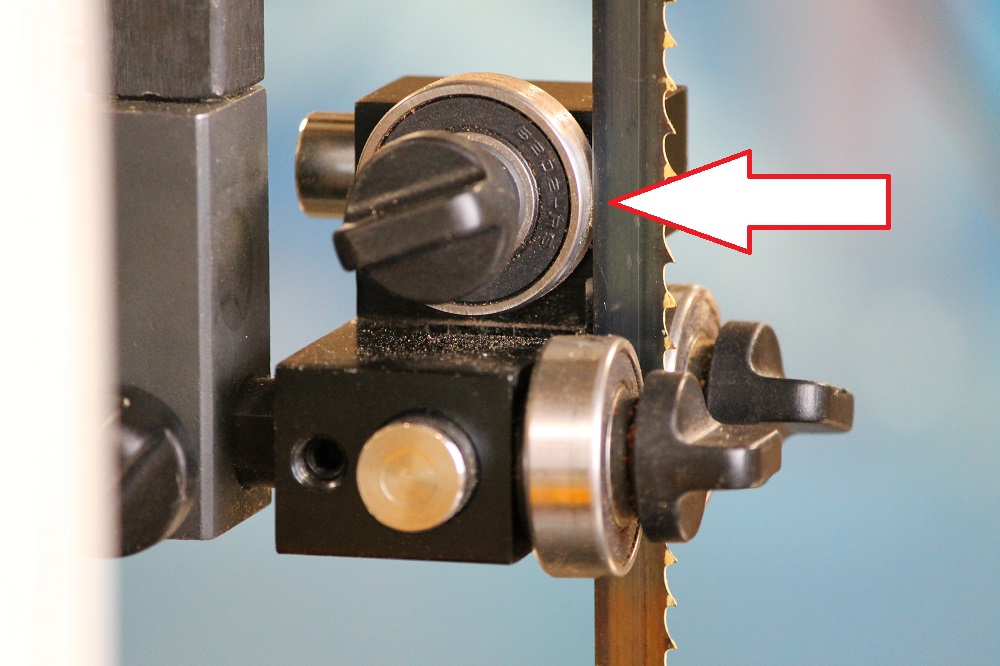

Use a Tension Gauge

A tension gauge is a useful tool for accurately measuring and adjusting the blade tension. It allows you to apply the appropriate amount of force, ensuring the blade is within the recommended tension range.

Perform Regular Maintenance

Regularly inspecting and maintaining your bandsaw, including checking for blade wear and tension, can help identify issues early on and prevent them from escalating into significant problems.

In conclusion, over tightening a bandsaw blade can have severe consequences, including blade breakage, premature wear, and machine damage. It is crucial to strike a balance between sufficient tension for optimal cutting performance and excessive tension that can lead to problems. By following the manufacturer’s guidelines and implementing proper tensioning techniques, you can ensure the longevity of your bandsaw blade and maintain the highest level of safety and efficiency in your woodworking projects.

Key Takeaways: Can You Over Tighten a Bandsaw Blade?

- Over tightening a bandsaw blade can cause it to break or wear out faster.

- Proper tension is important to ensure smooth and precise cuts.

- Follow the manufacturer’s guidelines for tensioning the blade.

- Regularly check and adjust the tension to maintain optimal performance.

- Using a tension gauge can help you achieve the correct blade tension.

Frequently Asked Questions

Are you wondering about the effects of over-tightening a bandsaw blade? We’ve got you covered! Here are some commonly asked questions related to the topic.

1. How can over-tightening a bandsaw blade affect its performance?

When you over-tighten a bandsaw blade, you risk putting excessive strain on the blade itself and the bandsaw’s components. This can lead to premature wear and tear, making the blade more prone to snapping or becoming dull. Over-tightening can also affect the accuracy and smoothness of your cuts, resulting in rougher finishes and potential damage to your workpiece. It’s crucial to find the right balance when tensioning your bandsaw blade.

Additionally, over-tightening a bandsaw blade may cause unnecessary stress on the bandsaw’s motor, leading to decreased performance and a shorter lifespan. It’s important to follow the manufacturer’s recommendations and guidelines for proper blade tensioning to ensure optimal performance and longevity of both the blade and the bandsaw itself.

2. What are the signs of an overly tight bandsaw blade?

If your bandsaw blade is overly tight, you may notice several signs. The blade might emit a higher pitched or strained sound while in operation. You might also experience excessive vibrations, which can negatively impact the accuracy of your cuts. Another indicator is increased resistance or difficulty in feeding the workpiece through the blade. These signs are often a result of cutting too much tension into the blade, and it’s important to address them promptly to avoid any further damage or issues.

To ensure the proper tension of your bandsaw blade, you can refer to the manufacturer’s recommendations or use a tensioning gauge to measure the tension. Maintaining the correct tension will not only enhance the performance of your bandsaw but also contribute to the longevity of your blade.

3. Can over-tightening a bandsaw blade lead to blade breakage?

Yes, over-tightening a bandsaw blade can contribute to blade breakage. When the blade is excessively tight, it loses its flexibility and becomes more prone to stress and fatigue. This can lead to cracks or fractures, ultimately causing the blade to snap during operation. Additionally, the increased tension can cause the blade to heat up more quickly, further reducing its lifespan. It’s essential to strike the right balance when tensioning your bandsaw blade to prevent any unwanted breakage.

Regularly inspecting your blade for signs of wear, such as cracks, missing teeth, or uneven wear patterns, is also crucial. By being proactive and addressing any issues promptly, you can minimize the risk of blade breakage and ensure safer and more efficient cutting operations.

4. What are the potential risks of over-tightening a bandsaw blade?

Over-tightening a bandsaw blade can have several potential risks. As mentioned earlier, it can lead to premature wear and tear of the blade, increasing the chances of breakage or dullness. In addition to this, an overly tight blade may cause excessive strain on the bearings, guides, and other components of the bandsaw, leading to accelerated wear and potential damage. These risks not only affect the performance of your bandsaw but can also impact your safety in the workshop.

Another risk is the reduced ability of an overstressed blade to effectively clear sawdust. This can result in clogging, reduced cutting efficiency, and may even cause the blade to overheat. By adhering to the manufacturer’s recommended tension range, you can mitigate these risks and ensure a smoother, safer, and more productive cutting experience.

5. How to achieve the correct tension for a bandsaw blade?

To achieve the correct tension for a bandsaw blade, start by referring to the manufacturer’s guidelines and recommendations for your specific bandsaw model. They usually provide a range of tension that is suitable for the blade size and material you are working with. Additionally, you can use a tensioning gauge specifically designed for bandsaws to measure the tension accurately.

When tensioning the blade, aim for a tension that is sufficient to prevent side-to-side movement but not overly tight. The blade should have a slight amount of flex when lightly pressed from the side. It’s important to note that different blades may require slightly different tensions, so be sure to adjust accordingly when switching between blade types. By finding the right balance and tensioning your bandsaw blade correctly, you can optimize cutting performance, blade lifespan, and minimize the risk of damage to your bandsaw and workpiece.

Summary

You might think that tightening a bandsaw blade really tight is a good idea, but it’s not! Over-tightening the blade can cause a lot of problems. It can lead to excessive blade stress, blade breakage, and even damage to the bandsaw itself. So, it’s important to find the right tension for your bandsaw blade and not go overboard.

When it comes to tightening your bandsaw blade, remember to follow the manufacturer’s recommendations. Don’t crank it too tight because that can cause more harm than good. A properly tensioned blade will provide better cutting performance and prolong the life of your blade and bandsaw. So, take it easy and find that sweet spot for your bandsaw blade tension.