Are you wondering whether it’s possible to resurface a flywheel on a lathe? Well, you’ve come to the right place! Flywheels are an essential component of many mechanical systems, and over time, they can become worn or damaged. In this article, we’ll explore the process of resurfacing a flywheel on a lathe and discuss its benefits.

Now, you might be wondering, what exactly is a flywheel? Think of it as a heavyweight that stores rotational energy. It helps smooth out the engine’s power delivery and keeps it running smoothly. However, continuous use can cause the flywheel surface to wear down or develop imperfections, affecting its performance. That’s where resurfacing comes in.

So, can you resurface a flywheel on a lathe? The short answer is yes! A lathe is a powerful machine used for cutting and shaping materials, and it can be used to restore a flywheel’s surface. By carefully mounting the flywheel on the lathe and using specialized tools, mechanics can remove the old surface and create a smooth, even, and properly functioning flywheel.

So, if you’re having issues with your flywheel or want to prevent potential problems down the line, resurfacing it on a lathe can be an effective solution. In the upcoming sections, we’ll dive deeper into the process and share some best practices to ensure a successful outcome. So, let’s get started!

Resurfacing a flywheel on a lathe can be a straightforward process if you have the right tools and knowledge. Follow these steps to resurface a flywheel:

- Remove the flywheel from the engine.

- Clean the flywheel surface.

- Reinstall the flywheel back into the engine.

By following these steps, you can successfully resurface a flywheel on a lathe.

Can You Resurface a Flywheel on a Lathe?

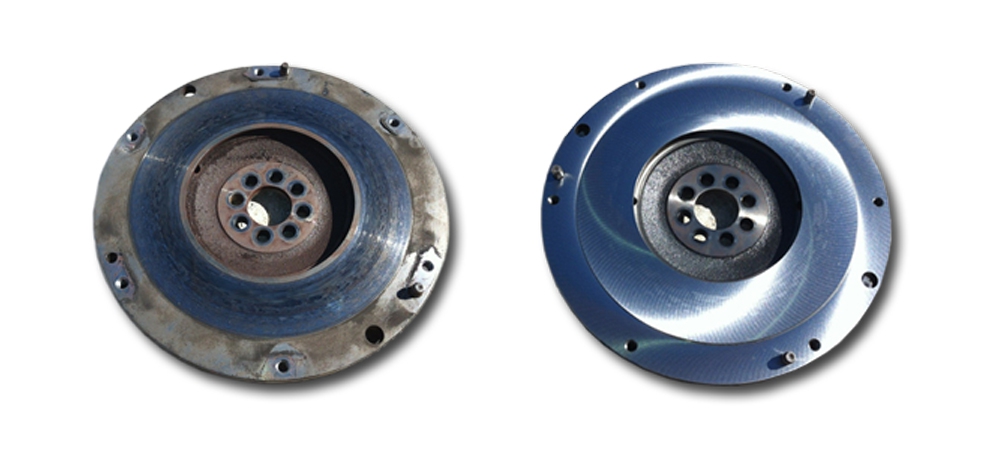

Flywheels play a crucial role in many mechanical systems, including engines and machinery. Over time, these flywheels can become worn down or damaged, affecting their performance and efficiency. The question arises: can you resurface a flywheel on a lathe? In this article, we will delve into the process of resurfacing flywheels on a lathe, discussing the benefits, steps involved, and considerations to keep in mind.

The Process of Resurfacing a Flywheel on a Lathe

Resurfacing a flywheel involves removing a small layer of material from its surface to restore its smoothness and functionality. This process can be done using a lathe, a machine tool that rotates the workpiece against a cutting tool. Here are the steps involved in resurfacing a flywheel on a lathe:

Step 1: Preparation

Before beginning the resurfacing process, it is crucial to prepare the flywheel and the lathe. Start by cleaning the flywheel thoroughly to remove any dirt, grease, or debris that could interfere with the cutting process. Additionally, ensure that the lathe is properly calibrated and in good working condition.

Once both the flywheel and lathe are ready, mount the flywheel securely onto the lathe’s chuck. This will help keep the flywheel in place during the cutting process and prevent any unnecessary vibrations.

Step 2: Cutting the Flywheel

With the flywheel securely mounted, it’s time to begin cutting. Start by adjusting the cutting tool and feed rate based on the desired depth of cut and the condition of the flywheel. It is recommended to make multiple shallow cuts rather than a single deep cut to ensure a more precise and even surface.

As the lathe rotates the flywheel, gradually move the cutting tool across its surface, removing a small amount of material with each pass. Take care to maintain a consistent speed and pressure to achieve a smooth and even finish. Repeat this process until the desired surface is achieved.

Step 3: Finishing Touches

Once the cutting process is complete, it’s essential to perform some finishing touches to ensure a high-quality resurfaced flywheel. Use a file or sandpaper to smooth out any rough edges or imperfections left by the cutting tool. This will help improve the overall surface finish and ensure optimal performance.

Finally, clean the flywheel once again to remove any metal shavings or debris. Inspect the surface for any remaining rough spots and make any necessary adjustments to achieve the desired level of smoothness.

Benefits of Resurfacing a Flywheel on a Lathe

Resurfacing a flywheel on a lathe offers several benefits, including:

- Improved Performance: By restoring the flywheel’s surface to its original smoothness, resurfacing helps optimize its performance, ensuring better energy storage and transmission.

- Extended Lifespan: A resurfaced flywheel can last longer due to the removal of wear and tear, reducing the need for frequent replacements.

- Cost-Effective: Resurfacing is often more cost-effective than purchasing a new flywheel, making it an attractive option for those on a budget.

- Reduced Vibration and Noise: A smooth surface helps minimize vibrations and noise during operation, leading to a quieter and more comfortable working environment.

Can You Resurface a Flywheel on a Lathe? Key Takeaways:

- Yes, you can resurface a flywheel on a lathe.

- Resurfacing a flywheel involves removing any imperfections or unevenness on its surface.

- Using a lathe, the flywheel is placed securely and rotated against a cutting tool to achieve a smooth and even surface.

- Resurfacing a flywheel can improve its performance and prolong its lifespan.

- It is recommended to seek professional assistance or have proper knowledge and experience before attempting to resurface a flywheel on a lathe.

Frequently Asked Questions

Welcome to our FAQ section on resurfacing flywheels using a lathe. Here, we will tackle some common questions regarding this process and provide you with detailed answers. Read on to find out more!

1. How does resurfacing a flywheel on a lathe benefit my vehicle?

Resurfacing a flywheel on a lathe offers several benefits for your vehicle. Firstly, it helps restore a smooth and level surface, which is crucial for optimal clutch engagement. By removing any imperfections or warping, it enhances the overall performance and longevity of your clutch system. Additionally, resurfacing the flywheel helps prevent clutch slippage and ensures maximum power transfer between the engine and the drivetrain.

Moreover, a properly resurfaced flywheel can eliminate vibrations and chatter that might occur during clutch engagement, resulting in a smoother and more comfortable driving experience. So, whether you’re looking to improve performance or solve issues related to clutch engagement, resurfacing the flywheel on a lathe is a worthwhile investment.

2. Can any flywheel be resurfaced on a lathe?

In general, most flywheels can be resurfaced on a lathe. However, it’s essential to consider a few factors before proceeding. Firstly, the flywheel needs to be in a condition where resurfacing can effectively address any issues. If the flywheel is severely damaged, cracked, or beyond repair, it may need to be replaced instead of resurfaced.

Additionally, the dimensions of the flywheel need to be within acceptable limits for resurfacing. This ensures that the proper thickness and diameter can be maintained after removing a small amount of material during the resurfacing process. An experienced technician can assess the flywheel’s condition and determine if it is suitable for resurfacing on a lathe.

3. What is the typical cost for resurfacing a flywheel on a lathe?

The cost of resurfacing a flywheel on a lathe can vary depending on several factors, including the type of vehicle, the condition of the flywheel, and the specific shop or service provider. On average, you can expect to pay between $50 and $150 for this service. However, it’s always a good idea to contact local automotive shops or machine shops to get a more accurate estimate based on your specific requirements.

Keep in mind that resurfacing the flywheel is often more cost-effective than replacing it entirely. Additionally, combining flywheel resurfacing with other clutch-related services, such as clutch replacement or installation, may be offered at a discounted package rate. So, it’s worth exploring different options to find the best deal for your needs.

4. How long does the process of resurfacing a flywheel on a lathe take?

The time it takes to resurface a flywheel on a lathe can vary depending on a few factors. Generally, this process can be completed within a few hours, assuming there are no significant issues or complications. However, it’s important to consider that additional time may be required if the flywheel requires any repairs or if there is a backlog of work at the service provider.

If you’re planning to have your flywheel resurfaced, it’s a good idea to contact the service provider in advance and inquire about the estimated turnaround time. This will help you plan accordingly and ensure that your vehicle is off the road for the minimum amount of time necessary.

5. Can I attempt to resurface a flywheel on a lathe myself?

Resurfacing a flywheel on a lathe is a specialized task that requires knowledge, experience, and the right equipment. It is generally not recommended for inexperienced individuals to attempt this procedure themselves. Utilizing a lathe for flywheel resurfacing involves precise measurements, correct tooling, and the expertise to ensure proper alignment and smooth operation.

To ensure a quality resurfacing job and to prevent any potential damage to your flywheel, it is best to leave this task to a professional. An experienced automotive technician or a machine shop that specializes in flywheel resurfacing will have the necessary expertise and equipment to perform the job accurately and efficiently while maintaining the integrity of your flywheel.

Summary

If you’re wondering whether you can resurface a flywheel on a lathe, the answer is yes! Resurfacing a flywheel can improve its performance and extend its lifespan. To do this, you’ll need to carefully remove the flywheel from the engine and secure it onto the lathe. Using special cutting tools, you can then remove any imperfections on the surface of the flywheel. Once the resurfacing is complete, you should carefully reinstall the flywheel back onto the engine, ensuring it is properly aligned. Resurfacing a flywheel can be a complex task, so it’s always a good idea to seek guidance from a professional or experienced mechanic.

In addition to improving performance, resurfacing a flywheel can also help to eliminate any shuddering or slipping that may occur during clutch engagement. By creating a smooth and even surface, the flywheel can provide better friction and grip, resulting in a smoother operation overall. Remember, though, that not all flywheels can be resurfaced. Some flywheels may be too damaged or worn beyond repair, in which case a replacement may be necessary. It’s important to assess the condition of the flywheel before attempting any resurfacing procedures.