Are you wondering if you can sharpen carbide lathe tools? Well, you’ve come to the right place! In this article, we’ll explore the ins and outs of sharpening carbide lathe tools and provide you with some valuable insights. So, let’s dive in and discover the answer together!

Carbide lathe tools are known for their durability and long lifespan, but like any tool, they eventually require sharpening. If you’re a woodworking enthusiast or a hobbyist who loves working with a lathe, you might be curious about the process of sharpening carbide lathe tools. Don’t worry, we’ve got you covered! We’ll explain the steps involved in sharpening these tools and share some tips to help you get the best results.

Sharpening carbide lathe tools can seem like a daunting task, especially if you’re new to it. However, with the right knowledge and techniques, it can be a rewarding and satisfying process. So, whether you’re a seasoned professional or just starting to explore the world of lathe work, stay tuned as we uncover the secrets to sharpening carbide lathe tools and help you take your woodworking skills to the next level!

Want to know if you can sharpen carbide lathe tools? Absolutely! Carbide lathe tools can be sharpened and restored to their original cutting abilities. Here’s how:

- Secure the carbide tool in a vise, ensuring it’s stable.

- Use a diamond file or grinding wheel to reshape the tool’s cutting edge.

- Maintain a consistent angle while sharpening to achieve optimal results.

- Inspect the tool for any signs of damage or wear.

- Finish by honing the cutting edge with fine grit sandpaper or a sharpening stone.

By following these steps, you can successfully sharpen your carbide lathe tools.

Can You Sharpen Carbide Lathe Tools?

Carbide lathe tools are known for their durability and long-lasting cutting edges. However, like any other tool, they eventually become dull and require sharpening. This raises the question: Can you sharpen carbide lathe tools? The answer is yes, but it requires a different approach compared to sharpening conventional high-speed steel (HSS) tools. In this article, we will explore the process of sharpening carbide lathe tools, the tools and techniques required, and some tips for optimizing the sharpening process.

The Process of Sharpening Carbide Lathe Tools

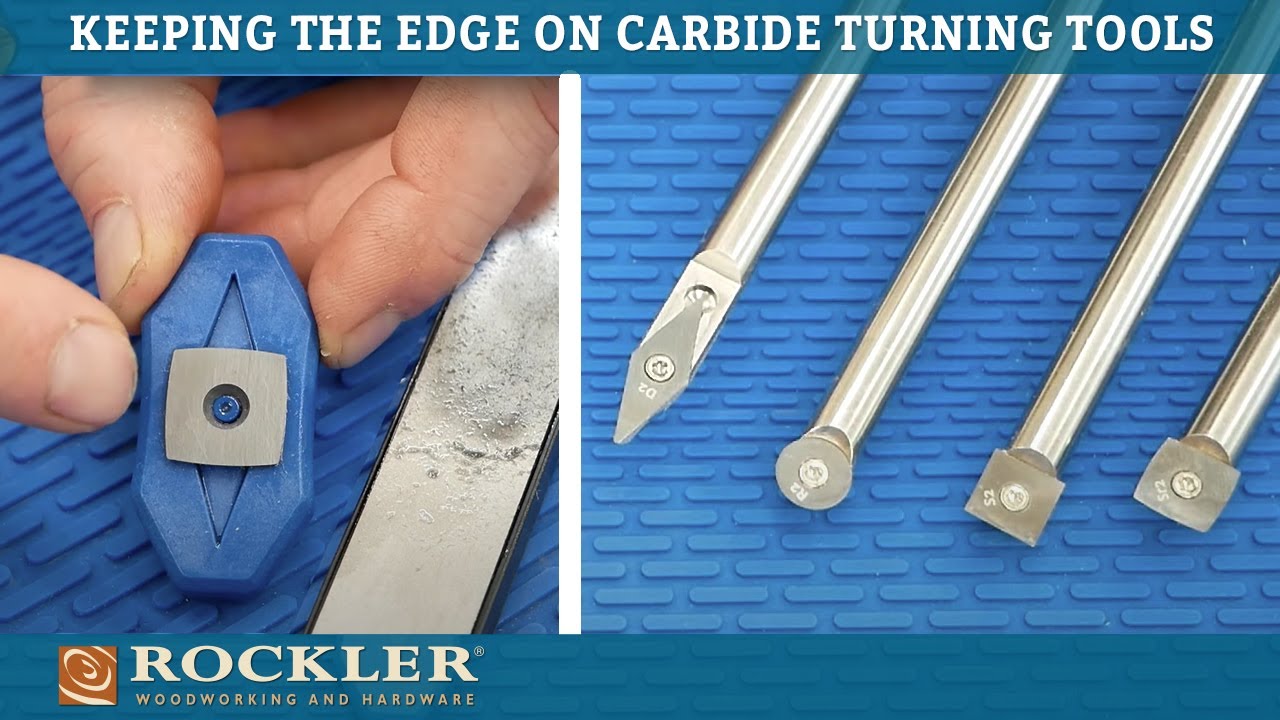

Sharpening carbide lathe tools involves grinding away the dull material on the cutting edge to restore its sharpness. Carbide is a hard material that can withstand high temperatures, making it difficult to sharpen using conventional methods. The most common way to sharpen carbide tools is by using a diamond grinding wheel. The diamond grit is capable of removing material from the carbide without overheating it.

To sharpen a carbide lathe tool, start by securely clamping it in a tool holder or jig. Then, carefully position the tool against the grinding wheel at the correct angle. Slowly move the tool back and forth while maintaining a constant angle and applying even pressure. Take breaks in between to prevent overheating. Repeat this process until the cutting edge is sharp. It is important to note that carbide tools have a negative rake angle, so be sure to maintain the original angle while sharpening.

After sharpening, it is recommended to hone the cutting edge using a fine-grit diamond hone or a honing compound. This helps to remove any roughness left by the grinding wheel and further improves the sharpness of the tool. Finally, clean the tool and inspect the cutting edge under a bright light to ensure it is free from any imperfections.

Tools and Techniques for Sharpening Carbide Lathe Tools

When it comes to sharpening carbide lathe tools, having the right tools and techniques can make a significant difference. Here are some essential tools and techniques to consider:

1. Diamond Grinding Wheel

A diamond grinding wheel is the most effective tool for sharpening carbide lathe tools. It is specifically designed to grind hard materials such as carbide without causing overheating. When choosing a diamond grinding wheel, consider factors such as grit size, wheel diameter, and wheel thickness to ensure you have the right wheel for the job.

Benefits of Using a Diamond Grinding Wheel:

- Diamond grit ensures efficient material removal

- Reduced risk of overheating the carbide

- Long-lasting and durable

- Available in various grit sizes for different sharpening needs

2. Tool Holder or Jig

A tool holder or jig is essential for securely holding the carbide lathe tool during the sharpening process. It provides stability and ensures accurate positioning against the grinding wheel. Look for a tool holder or jig that is compatible with your lathe and provides the necessary support and adjustability.

Tips for Using a Tool Holder or Jig:

- Ensure the tool is securely clamped in the holder or jig

- Position the tool at the correct angle for sharpening

- Maintain a steady hand while moving the tool back and forth

- Take breaks to prevent overheating

3. Honing Tools

Honing tools are used to refine and polish the cutting edge after grinding. They help to remove any roughness left by the grinding wheel and improve the overall sharpness of the tool. There are various honing tools available, including diamond hones and honing compounds.

Tips for Honing Carbide Lathe Tools:

- Choose a fine-grit diamond hone or honing compound for a polished finish

- Gently stroke the hone along the cutting edge, maintaining the original angle

- Apply light pressure and take your time to achieve the desired sharpness

- Clean the tool after honing to remove any residue

By utilizing the right tools and techniques, you can effectively sharpen carbide lathe tools and extend their lifespan. Remember to always prioritize safety when working with grinding wheels and wear appropriate protective gear.

Tips for Optimizing the Sharpening Process

Sharpening carbide lathe tools can be a challenging task, but with the right approach, it can be done efficiently. Here are some tips to help you optimize the sharpening process:

1. Take Your Time

Sharpening carbide lathe tools requires patience and attention to detail. Rushing through the process can lead to mistakes and an inadequate result. Take your time, follow the correct techniques, and maintain a steady hand to achieve the best results.

2. Keep the Grinding Wheel Clean

A clean grinding wheel is essential for effective sharpening. As you grind, carbide particles can accumulate on the wheel, reducing its effectiveness. Use a dressing tool to clean the wheel periodically and maintain its cutting efficiency.

3. Regularly Inspect and Re-Sharpen

Regularly inspecting your carbide lathe tools for signs of wear and dullness is important. As soon as you notice a decrease in performance, it’s time to re-sharpen the tool. This will ensure that you always have sharp tools at your disposal for efficient lathe work.

Sharpening carbide lathe tools may seem daunting at first, but with practice and the right tools, it becomes an essential skill for any lathe operator. By following the proper techniques and taking the time to sharpen your tools correctly, you can achieve sharp, durable cutting edges that will enhance your lathe work. Remember to prioritize safety, wear protective gear, and enjoy the process of creating impeccably sharpened carbide lathe tools.

Key Takeaways: Can You Sharpen Carbide Lathe Tools?

- Yes, carbide lathe tools can be sharpened.

- Special diamond abrasive wheels are used for sharpening carbide tools.

- Proper technique and care are important when sharpening carbide lathe tools.

- Sharpening reduces tool wear and improves cutting performance.

- It is recommended to consult a professional or reference a sharpening guide for best results.

Frequently Asked Questions

Are you wondering how to sharpen carbide lathe tools effectively? Look no further! We have answered some common questions below to help you master the art of sharpening carbide lathe tools with ease.

1. What are carbide lathe tools?

Carbide lathe tools are cutting tools used in lathe machines, particularly known for their durability and resistance to wear. They consist of a carbide insert attached to a tool holder. Compared to traditional high-speed steel (HSS) tools, carbide tools offer better performance and longevity, making them a popular choice among woodturners and metalworkers.

Carbide inserts, the cutting edge of these tools, are made of tungsten carbide particles held together with a cobalt binder. This combination makes carbide inserts extremely hard and capable of withstanding high temperatures, allowing them to cut through tough materials effortlessly.

2. Can you sharpen carbide lathe tools?

Yes, you can sharpen carbide lathe tools, but it requires a different approach than sharpening traditional steel tools. Carbide inserts are not sharpened in the same way as HSS tools. Instead of grinding the carbide inserts, you need to replace them when they become dull. However, you can sharpen the cutting edge of carbide inserts using a diamond hone or a sharpening stone.

Keep in mind that when sharpening carbide lathe tools, you are not grinding them to a new shape but working to maintain the sharpness of the existing cutting edge. It is important to handle the inserts with care to avoid damaging them during the sharpening process.

3. How often should you sharpen carbide lathe tools?

The frequency of sharpening carbide lathe tools depends on several factors, such as the type of material you are working with, the complexity of the project, and the quality of the cuts you are achieving. As a general rule, you should check the sharpness of your carbide inserts regularly and sharpen them as soon as you notice a drop in performance.

To maintain optimal performance, it’s recommended to inspect the inserts for signs of wear or chipping after each use. Regularly cleaning the inserts and keeping them free from dust and debris can also help prolong their sharpness and effectiveness.

4. What tools or equipment do you need to sharpen carbide lathe tools?

To sharpen carbide lathe tools effectively, you will need a few essential tools and equipment. These include a diamond hone or sharpening stone, honing oil or lubricant, a flat surface, and a pair of protective gloves. The diamond hone or sharpening stone should have a grit suitable for sharpening carbide inserts.

Additionally, having a tool rest or jig designed specifically for carbide inserts can make the sharpening process more precise and efficient. It is important to invest in quality tools and equipment to ensure the best results and to maintain the longevity of your carbide lathe tools.

5. Are there any tips for sharpening carbide lathe tools?

When sharpening carbide lathe tools, it’s important to follow a few useful tips. Firstly, always refer to the manufacturer’s guidelines for sharpening carbide inserts as different brands may have specific recommendations. Secondly, ensure that you have a stable surface to work on, such as a sturdy workbench or sharpening station.

Use the appropriate amount of honing oil or lubricant to prevent overheating and to achieve a smoother sharpening process. Remember to apply even pressure and maintain a consistent angle when sharpening to ensure an even and precise cutting edge. Finally, after sharpening, remove any metal shavings or debris from the inserts and check for any signs of damage or wear.

Sharpening Carbide Cutters (Woodturning How-to)

Summary

Carbide lathe tools cannot be sharpened by hand, as they are too hard and require special equipment. The best way to sharpen them is to use a diamond grinding wheel. However, it is important to be careful not to overheat the tool and to use the correct wheel grit.

Using a diamond grinding wheel helps to maintain the sharpness and effectiveness of carbide lathe tools. It is also important to wear protective safety gear, such as goggles and gloves, when sharpening them. Sharpening carbide tools correctly will ensure they last longer and perform better.