If you’ve ever wondered whether you can turn quartz on a lathe, you’re in the right place! Let’s dive into the fascinating world of quartz and discover if it can be shaped using this popular tool.

Quartz is a beautiful and versatile mineral that is found in many different forms. From countertops to jewelry, it’s no wonder people are curious about working with it on a lathe. So, can you turn quartz on a lathe?

In this article, we’ll explore the possibilities and limitations of working with quartz on a lathe. Get ready to uncover the secrets of this mesmerizing material!

If you’re wondering if you can turn quartz on a lathe, the answer is yes! Quartz is a hard and durable material that can be shaped using a lathe. Here are the steps to turn quartz on a lathe:

- Secure the quartz piece in a lathe chuck.

- Select the appropriate lathe tool for cutting quartz.

Can You Turn Quartz on a Lathe?

Quartz is a mineral known for its durability and beauty. It is commonly used in jewelry-making, electronics, and various industrial applications. However, when it comes to turning quartz on a lathe, things become a bit more complicated. In this article, we will explore the challenges of turning quartz on a lathe and discuss whether it is possible to do so successfully.

#The Properties of Quartz that Affect Turning

1. Hardness

Quartz is one of the hardest minerals on Earth, ranking 7 on the Mohs scale of mineral hardness. This property makes it incredibly difficult to work with using traditional machining techniques, such as turning on a lathe. The hardness of quartz can cause excessive wear on cutting tools, leading to a shorter tool life and poor surface finishes. Additionally, the high hardness can result in vibrations and chatter during the turning process, making it challenging to achieve precision and accuracy.

To overcome the hardness of quartz, specialized cutting tools made from materials such as diamond or cubic boron nitride (CBN) are often used. These tools are exceptionally hard and can withstand the demands of machining quartz. However, they can be expensive and require careful handling and maintenance.

2. Heat Resistance

Another factor that affects turning quartz on a lathe is its heat resistance. Quartz has a high melting point of around 1650 degrees Celsius, which means it can withstand high temperatures during machining. However, the heat generated during the turning process can cause the quartz to expand, leading to dimensional inaccuracies and potential cracking.

To prevent heat-related issues, it is crucial to use proper coolant and lubrication while turning quartz. Coolants help dissipate heat, reducing the risk of thermal damage to the material. Lubricants also provide additional heat resistance and improve the cutting action. Choosing the right coolant and lubricant is essential to ensure a successful turning operation on quartz.

3. Brittleness

Quartz is a brittle material, meaning it is prone to cracking or breaking under stress. This brittleness can pose challenges when turning quartz on a lathe, as cutting forces can induce internal stresses and cause the material to fracture. Care must be taken to minimize the impact of cutting forces and prevent excessive strain on the quartz.

One approach to reduce the risk of fracturing is to use light cuts and slow feed rates during the turning process. This allows for better control and reduces the chances of sudden stress build-up. Additionally, proper tool geometry and settings can also help alleviate the effects of brittleness on quartz.

#Can Quartz Be Successfully Turned on a Lathe?

The Challenges of Turning Quartz on a Lathe

While it is technically possible to turn quartz on a lathe, it is not a straightforward process. The unique properties of quartz, such as its hardness, heat resistance, and brittleness, pose significant challenges that require specialized techniques and tools. Turning quartz on a lathe requires expertise, patience, and careful attention to various factors to ensure a successful outcome.

1. Tools and Tooling

When turning quartz on a lathe, using the right tools and tooling is crucial. As mentioned earlier, cutting tools made from diamond or CBN are preferred for their hardness and durability. These tools should have the appropriate geometry, such as sharp cutting edges and proper rake angles, to ensure efficient cutting and minimize the risk of tool wear and chipping. Additionally, the lathe should be equipped with a rigid tool holder and a stable cutting platform to avoid vibrations and chatter.

Proper tooling also involves selecting the right inserts or tips, as well as the correct cutting speeds and feeds. High-speed machining techniques may be necessary to minimize heat build-up and reduce the risk of thermal damage to the quartz. Experimentation and testing are often required to find the optimal combination of tools, speeds, and feeds for turning quartz on a lathe.

2. Cooling and Lubrication

Cooling and lubrication play a critical role in successful quartz turning operations. As mentioned earlier, the heat generated during the turning process can cause the quartz to expand and potentially crack. The use of coolants and lubricants helps dissipate heat and reduce the risk of thermal damage. Proper flow and distribution of the coolant/lubricant should be ensured to effectively cool the cutting zone and prevent overheating.

Choosing the right coolant/lubricant is essential. Water-based coolants are commonly used, as they provide good heat dissipation and are cost-effective. However, alternative solutions, such as cutting oils or specialized lubricants, can also be beneficial in specific situations. It is important to consult with experts or manufacturers to determine the most suitable cooling and lubrication options for turning quartz on a lathe.

3. Workholding and Fixturing

Proper workholding and fixturing are essential for ensuring stability and precision when turning quartz on a lathe. The brittleness of quartz makes it prone to cracking under stress, so it is important to avoid excessive clamping forces that could induce internal damage. Soft jaws or custom-designed fixtures may be used to securely hold the quartz in place without applying excessive pressure.

Additionally, workpiece orientation and alignment should be carefully considered. Quartz crystals often have natural cleavage planes, which are planes of weakness along which the material is prone to splitting. Aligning the crystal in a way that minimizes stress on these planes can help prevent fractures during turning.

Tips for Successful Quartz Turning on a Lathe

1. Start with small test pieces or scrap material before moving on to more valuable or intricate quartz pieces. This allows you to familiarize yourself with the specific challenges and characteristics of turning quartz without the risk of ruining a valuable workpiece.

2. Pay close attention to chip control and clearance. Quartz produces small, abrasive chips that may interfere with the cutting process. Ensuring proper chip clearance and evacuation is essential for maintaining smooth and efficient cutting.

3. Regularly inspect and replace cutting tools as needed. Diamond or CBN tools are hard but can still wear out over time. Keep a close eye on tool wear and replace dull or damaged tools promptly to maintain optimal cutting performance.

4. Seek guidance and advice from experienced machinists or manufacturers specializing in quartz turning. They can provide valuable insights and recommendations based on their expertise and firsthand experience.

5. Practice patience and take your time. Turning quartz on a lathe requires a steady hand and careful attention to detail. Rushing the process can lead to mistakes and unsatisfactory results.

Remember, turning quartz on a lathe is a complex endeavor that requires specialized knowledge and equipment. If you’re a beginner, it’s advisable to seek professional help or training before attempting to turn quartz on your own.

Key Takeaways: Can You Turn Quartz on a Lathe?

– Quartz is a very hard material, making it difficult to turn on a lathe.

– It requires specialized tools, such as diamond-tipped cutters, to work with quartz on a lathe.

– The high precision and skill needed to turn quartz on a lathe make it a complex process.

– Quartz can be fragile and prone to chipping or cracking during the turning process.

– It is recommended to seek professional help or guidance when attempting to turn quartz on a lathe.

Frequently Asked Questions

Are you curious about the possibility of turning quartz on a lathe? Here are some frequently asked questions regarding this topic:

Can quartz be turned on a lathe?

Quartz, being a hard and brittle material, is challenging to turn on a lathe. The hardness of quartz makes it prone to chipping, and its brittleness poses the risk of fracture. Additionally, quartz has a tendency to generate heat quickly when subjected to friction, making the turning process even more difficult.

However, with careful and precise techniques, it is possible to turn quartz on a lathe. Using specialized tools and slow speeds, experienced craftsmen can shape quartz into desired forms. It requires steady hands, patience, and deep understanding of the material’s properties.

What tools are needed to turn quartz on a lathe?

Turning quartz on a lathe requires specific tools designed for working with hard materials. Some essential tools include diamond-tipped cutting tools, which can withstand the hardness of quartz. These cutting tools should be chosen based on the specific type of quartz being turned and the desired outcome.

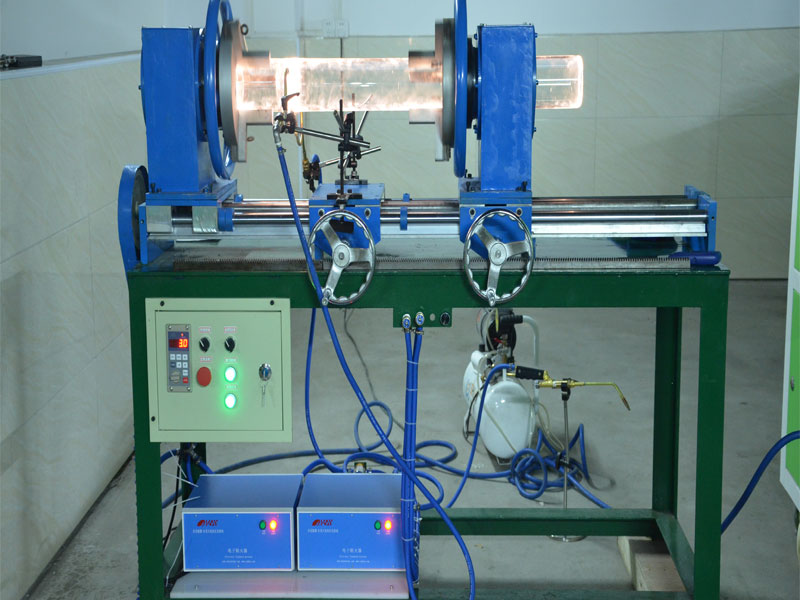

In addition to cutting tools, a lathe with adjustable speed settings is necessary to ensure proper control and precision. It is also recommended to have a cooling system in place to manage the heat generated during the turning process. With the right tools and equipment, the process of turning quartz on a lathe can be more manageable.

What are the challenges of turning quartz on a lathe?

One of the main challenges of turning quartz on a lathe is its hardness. Quartz ranks seven on the Mohs hardness scale, making it harder than many other materials. This hardness makes it difficult to shape quartz without chipping or damaging the material.

Furthermore, quartz is brittle, meaning it is susceptible to fractures when exposed to pressure or impact. This brittleness adds another layer of complexity to the turning process, as any mishandling can lead to unwanted cracks or breaks. Managing the heat generated during the turning process is also a challenge, as quartz has a low thermal conductivity and can become damaged if exposed to excessive heat.

What precautions should be taken when turning quartz on a lathe?

When turning quartz on a lathe, several precautions should be taken to ensure the best possible outcome. Firstly, it is essential to work with experienced craftsmen who have expertise in working with hard materials like quartz. Their knowledge and skills will help minimize the risks involved.

Additionally, it is crucial to use appropriate safety gear, such as protective eyewear and gloves, to shield oneself from potential injury. The lathe should be equipped with safety features, and the turning area should be well-ventilated to prevent the inhalation of quartz dust.

Can quartz be used for precise and intricate lathe work?

While quartz is generally more challenging to work with due to its hardness and brittleness, it is still possible to achieve precise and intricate lathe work with this material. Skilled craftsmen with extensive experience in working with quartz can create intricate designs, shapes, and patterns by using specialized tools and techniques.

However, it’s important to note that working with quartz requires a high level of precision and attention to detail. Any slight mistake or miscalculation can ruin the workpiece. Therefore, it is crucial to work with experienced professionals who have a deep understanding of the material’s properties and the intricacies of lathing quartz.

Stone Turning- Field Stone to Granite Cup

Summary

So, can you turn quartz on a lathe? The short answer is no. Quartz is extremely hard and brittle, making it challenging to machine without special tools and expertise. Additionally, the high heat generated during the machining process can cause the quartz to crack or shatter. It’s best to explore other techniques for working with quartz, like grinding or laser cutting, to achieve the desired shapes and designs.