Looking to get creative with your woodworking projects? Wondering if you can turn soft wood on a lathe? Well, you’ve come to the right place! Whether you’re a beginner or an experienced woodworker, this article will answer all your burning questions and provide some valuable insights. So, let’s dive in and discover the world of turning soft wood on a lathe!

Now you might be thinking, “Can I really use soft wood on a lathe?” The short answer is yes! Softwood, such as pine or cedar, can be turned on a lathe just as effectively as hardwood. In fact, softwood can offer unique advantages, like its affordability, lighter weight, and easier workability. So, if you have some softwood lying around, don’t hesitate to bring it to life on your lathe!

But hold on, before you start spinning that lathe, there are a few things to keep in mind. Softwood tends to be more prone to tearing and splintering compared to hardwood. To avoid this, it’s essential to use sharp tools, take lighter cuts, and be extra cautious during the turning process. With some patience, practice, and the right techniques, you’ll be able to transform that softwood into stunning creations on your lathe!

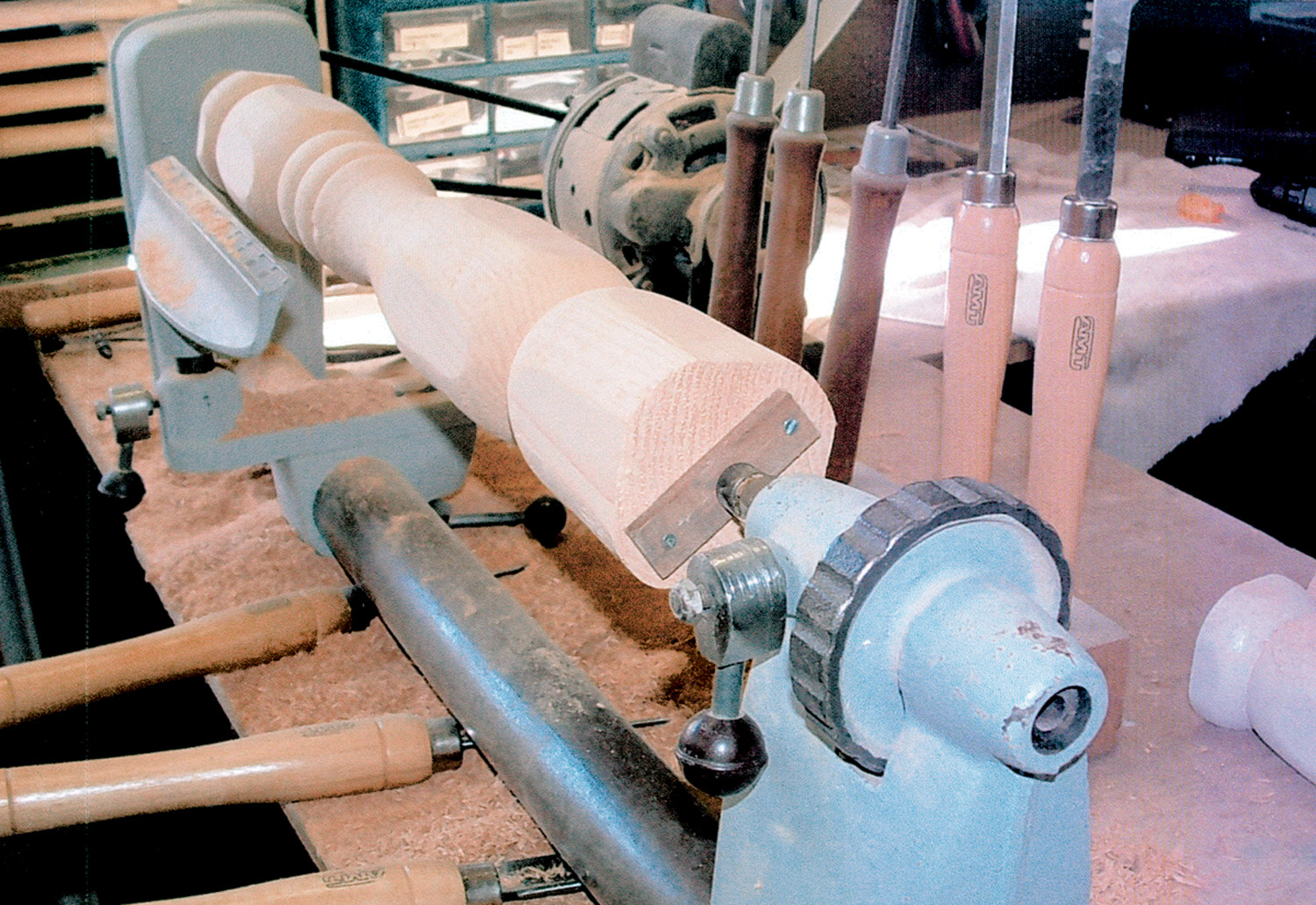

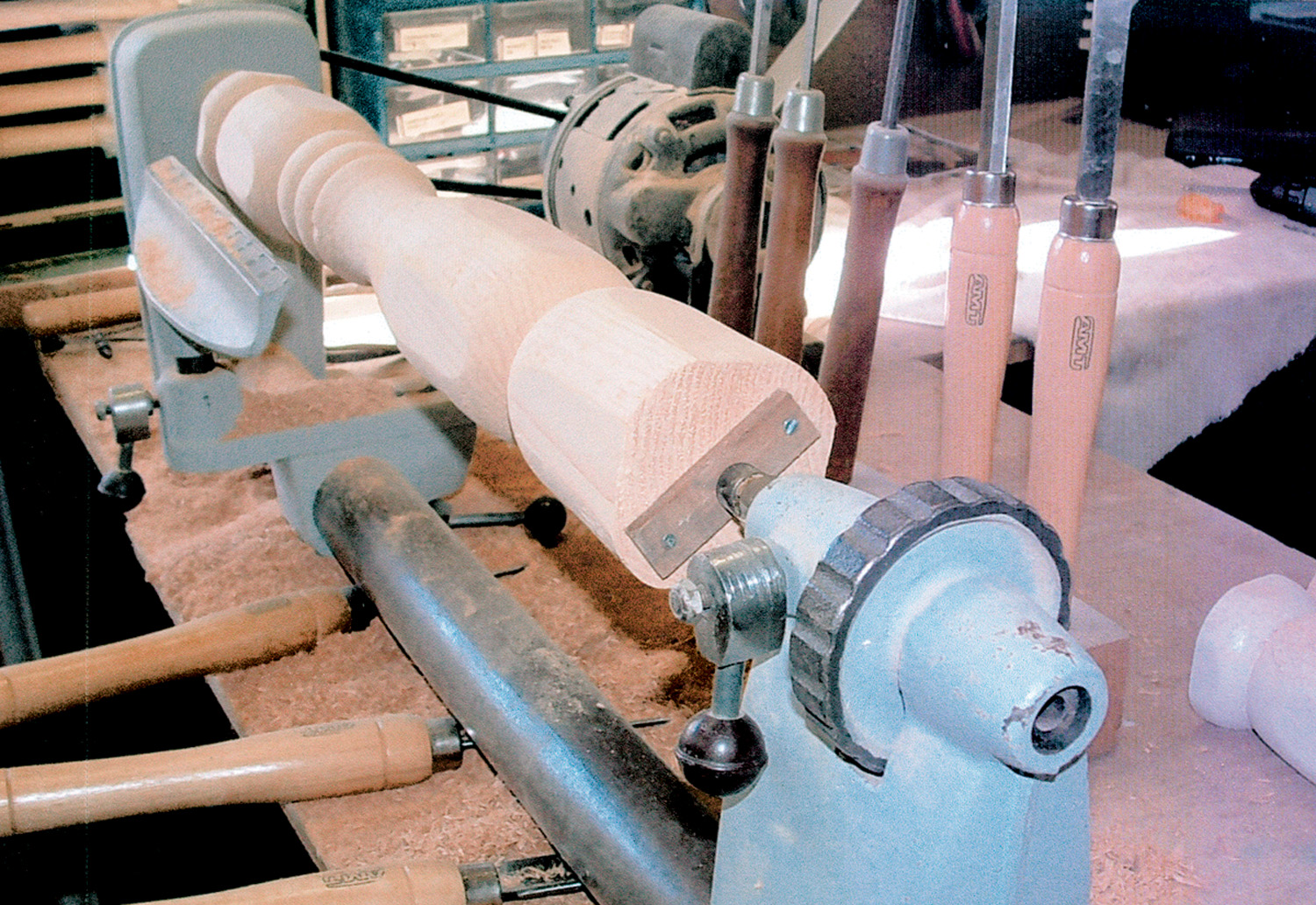

- Prepare the wood: Cut the softwood to the desired length and shape.

- Secure the wood: Use a lathe chuck or faceplate to secure the wood on the lathe.

- Mount the wood: Attach the wood onto the lathe spindle or between centers.

- Turn the wood: Use lathe tools to shape the wood by cutting and removing material.

- Finish the wood: Sand and finish the turned piece to your preference.

Happy woodturning!

Can You Turn Soft Wood on a Lathe?

Turning wood on a lathe is a popular woodworking technique that allows you to create beautiful and intricate designs. While many people use hardwoods for their projects, there is a common question that comes up: can you turn soft wood on a lathe? In this article, we will delve into the world of woodturning and explore whether soft woods can be successfully turned on a lathe. Whether you’re a beginner or an experienced woodworker, read on to find out more about this intriguing question.

Understanding Softwoods and Hardwoods

Before we dive into the specifics of woodturning, it’s essential to understand the differences between softwoods and hardwoods. Softwoods come from coniferous trees such as pines, cedars, and spruces. They are generally less dense than hardwoods and are often easier to work with due to their softer nature. Hardwoods, on the other hand, come from deciduous trees like oak, maple, and walnut. They tend to be denser and harder, making them popular choices for furniture and other durable projects.

The Challenges of Turning Soft Wood on a Lathe

While it is possible to turn soft woods on a lathe, there are some challenges to consider. Softwoods are typically less stable than hardwoods, which means they can be more prone to warping or cracking. Additionally, the softer nature of the wood can make it more difficult to achieve precise cuts and smooth finishes. However, with the right techniques and precautions, you can still create beautiful woodturning projects using soft woods.

One challenge of turning soft wood on a lathe is the increased risk of tear-out. Softwoods can have long, fibrous grains that can easily tear when cutting across the grain. This can result in a rough finish or even damaged wood. To minimize tear-out, it’s important to use very sharp tools and make light, deliberate cuts. Additionally, you may need to use specific cutting techniques, such as shear scraping or using a negative rake scraper, to achieve better results.

Another consideration when turning soft wood on a lathe is the use of appropriate finishing techniques. Softwoods tend to have more open pores compared to hardwoods, which can affect the final appearance of your project. Using a wood sealer or filler before applying a finish can help achieve a smoother surface. It’s also important to choose a finish that is suitable for softwoods, as some finishes may not adhere well or may alter the color of the wood.

Tips for Turning Soft Wood on a Lathe

While turning soft wood on a lathe presents its challenges, there are several tips and techniques that can help you achieve successful results. Here are some key tips to keep in mind:

- Invest in quality tools: Sharp, high-quality turning tools are essential for working with soft woods. Dull tools can result in tear-out and rough finishes.

- Take your time: Soft woods require patience and a slower feed rate. Rushing can lead to mistakes and unsatisfactory results.

- Use light cuts: Instead of taking deep cuts, opt for light cuts to minimize tear-out and achieve smoother finishes.

- Consider stabilization techniques: If you’re working with particularly unstable softwoods, you may want to consider stabilizing the wood with resin or other stabilization methods to reduce the risk of cracking or warping.

- Experiment with different finishes: Some finishes may react differently to soft woods, so it’s important to test different finishes on scrap pieces to find the one that gives you the desired result.

Other Factors to Consider in Woodturning

While the focus of this article has been on turning soft wood on a lathe, it’s worth mentioning that the type of wood is just one factor to consider in woodturning. Other factors such as grain orientation, moisture content, and the design of your project also play a significant role in the final outcome.

Benefits of Turning Soft Wood on a Lathe

Turning soft wood on a lathe can offer some unique benefits compared to working with hardwoods. Softwoods are often more readily available and less expensive than hardwoods, making them a cost-effective option. They can also be easier to shape and manipulate due to their softer nature, allowing for greater creativity and experimentation in your woodturning projects.

Conclusion

While turning soft wood on a lathe does present some challenges, it is indeed possible to create beautiful and intricate projects using soft woods. By understanding the characteristics of softwoods, employing the right techniques, and taking the necessary precautions, you can achieve satisfying results. Remember to be patient, invest in quality tools, and experiment with different finishes. Whether you choose to turn soft wood or hardwood, the art of woodturning offers endless possibilities for creativity and craftsmanship.

Key Takeaways: Can You Turn Soft Wood on a Lathe?

- Yes, you can turn soft wood on a lathe.

- Softwoods such as pine, spruce, and cedar are commonly used for woodturning.

- Turning soft wood on a lathe requires sharp tools to achieve clean cuts.

- You can create beautiful and functional projects using soft wood on a lathe.

- Remember to wear safety gear and follow proper techniques when woodturning.

Frequently Asked Questions

If you’re wondering about working with soft wood on a lathe, we’ve got answers for you! Check out these frequently asked questions:

1. What types of soft wood can be turned on a lathe?

Soft woods like pine, cedar, and spruce are suitable for turning on a lathe. Their lower density makes them easier to cut and shape, making them great choices for beginners or those looking for a smoother turning experience. These woods are also readily available and often more affordable compared to harder types of wood.

However, it’s crucial to consider the characteristics of the specific soft wood you’re working with. Some soft woods may have more knots, resin, or variations in grain, which can affect the turning process. It’s best to familiarize yourself with the specific properties of the soft wood you plan to work with.

2. Can soft wood be turned into intricate designs on a lathe?

Absolutely! Soft wood can be turned into beautifully intricate designs on a lathe. Although soft wood may be more prone to tearing or splintering compared to harder woods, with proper techniques and tools, it is still possible to create detailed and intricate designs.

It’s important to use sharp tools and take light cuts to avoid tear-out and minimize damage to the wood. Additionally, practicing on scrap pieces and experimenting with different cutting techniques can help you achieve the intricate designs you desire. With patience and practice, you’ll be able to create stunning masterpieces even with soft wood.

3. What are the benefits of turning soft wood on a lathe?

Turning soft wood on a lathe offers several benefits. Firstly, soft wood is generally more forgiving to work with, making it ideal for beginners or those still developing their turning skills. The lower density of soft wood allows for smoother and faster cutting, making the turning process more efficient.

Furthermore, soft woods are often more readily available and cost-effective compared to harder woods. This makes them a great choice for projects where budget or availability may be a concern. Soft wood can also have a unique and appealing aesthetic, with its lighter tones and visible grain patterns.

4. Are there any limitations when turning soft wood on a lathe?

While turning soft wood on a lathe has its advantages, it’s important to be aware of its limitations. Soft wood can be more prone to tear-out or splintering compared to harder woods, especially when working on intricate details or challenging grain patterns.

Additionally, the soft nature of the wood may restrict the size or weight of the projects you can create. Since soft wood is less dense, it may not be as suitable for large or heavy-turning projects. Consider the specific requirements and limitations of your project before deciding to use soft wood on a lathe.

5. How can I enhance the finish of soft wood turned on a lathe?

To enhance the finish of soft wood turned on a lathe, there are a few techniques you can employ. Sanding is an essential step in achieving a smooth and polished finish. Starting with a coarse grit sandpaper and gradually transitioning to finer grits will help you achieve a professional-looking result.

Using suitable wood finishes, such as varnishes or oils, can also bring out the natural beauty of the soft wood. These finishes not only provide protection but also add depth and richness to the wood’s appearance. Experimenting with different finishes and techniques can help you achieve the desired finish for your soft wood projects.

Summary

Turning soft wood on a lathe is possible, but it might be more challenging than using harder wood. Softwood, like pine or cedar, can be prone to tear-outs and splintering if not handled properly. It’s important to use sharp tools and take light cuts to avoid damaging the wood. Despite these challenges, with practice and patience, it is possible to create beautiful turned objects with softwood on a lathe.

Additionally, it’s important to consider the type of project you want to create. Softwood is more suitable for decorative or smaller items, rather than larger functional pieces. It’s also worth mentioning that the final finish can make a big difference in the appearance and durability of the turned wood. Applying a protective coating, like a sealant or varnish, can help enhance the beauty and lifespan of the softwood project. So, while turning soft wood on a lathe may require some extra care, it can still be a rewarding and enjoyable woodworking experience.