When it comes to working with plastic, you might be wondering, “Can you use a circular saw on plastic?” It’s a great question, and I’m here to give you the lowdown. So grab your safety goggles and let’s dive right in!

If you’ve ever used a circular saw before, you know how powerful and versatile this tool can be. But can it handle plastic? Well, the answer is not as straightforward as you might think. While a circular saw can be used on some types of plastic, there are a few factors you need to consider.

First off, the type of plastic matters. Some plastics, like PVC or acrylic, are known to be more saw-friendly than others. Additionally, the thickness of the plastic plays a role in determining whether a circular saw is a suitable choice. So, before you start cutting, it’s essential to know what kind of plastic you’re working with and its thickness.

In the next few paragraphs, we’ll explore the do’s and don’ts of using a circular saw on plastic, as well as some helpful tips to ensure a smooth and safe cutting experience. So keep reading to become a plastic-cutting pro in no time!

Can You Use a Circular Saw on Plastic?: Everything You Need to Know

Plastic is a versatile material used in various industries, from construction to automotive. When it comes to cutting plastic, many DIY enthusiasts and professionals wonder if they can use a circular saw. In this article, we will explore the possibilities, safety considerations, and techniques involved in using a circular saw on plastic. Read on to discover the dos and don’ts of cutting plastic with a circular saw, allowing you to tackle your projects with confidence.

Understanding the Properties of Plastic

Before diving into the intricacies of using a circular saw on plastic, it’s essential to understand the properties of this material. Plastic is a synthetic material made from polymers, which can be molded into various shapes and sizes. It offers excellent durability, flexibility, and resistance to moisture and chemicals, making it a popular choice for many applications.

However, plastic can be challenging to cut due to its composition. Some types of plastic are prone to melting, chipping, or cracking under the heat and pressure generated by power tools such as circular saws. Nevertheless, with the right techniques and safety precautions, it is possible to achieve clean and precise cuts on plastic using a circular saw.

Now, let’s delve into the details of using a circular saw on plastic, focusing on the dos and don’ts that will help you achieve optimal results while ensuring safety.

Choosing the Right Circular Saw Blade

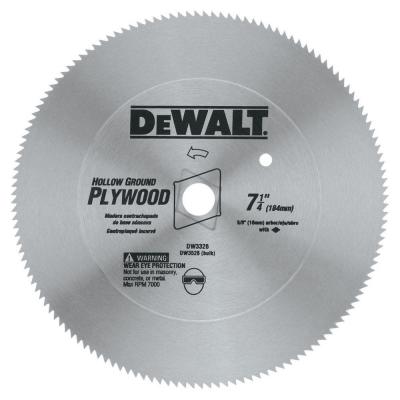

One of the most critical factors to consider when using a circular saw on plastic is the type of blade you use. Standard blades designed for cutting wood or metal are not suitable for plastic, as they can cause chipping, melting, or jagged cuts. To achieve clean and precise cuts on plastic, you need to invest in a high-quality plastic-cutting blade.

Plastic-cutting blades feature a high tooth count and have specially designed teeth that prevent melting and chipping. These blades usually have fine teeth with a high hook angle, allowing for smoother cutting and reduced heat buildup. When purchasing a plastic-cutting circular saw blade, look for labels such as “No Melt” or “Recommended for Plastic” to ensure you choose the right one for your project.

Additionally, consider the diameter and thickness of the blade. Smaller diameters are generally more suitable for thinner plastic sheets, while larger diameters are better for thicker materials. Make sure the blade has the appropriate thickness to avoid excessive vibration or bending during cutting.

Safety Precautions for Using a Circular Saw on Plastic

Safety should always be a top priority when using power tools, and using a circular saw on plastic is no exception. Here are some essential safety precautions to follow:

- Wear safety goggles and protective gloves to shield yourself from plastic debris.

- Secure the plastic sheet or workpiece firmly in place using clamps or a vise.

- Before cutting, inspect the plastic for any signs of damage or brittleness that may affect the cutting process.

- Set the cutting depth of the circular saw to a shallow level to minimize the risk of chipping or melting.

- Make sure the circular saw is unplugged or the battery is removed before changing the blade or making any adjustments.

- Apply steady and even pressure while cutting, allowing the blade to do the work without forcing it.

- Keep your hands and fingers away from the path of the saw blade at all times.

- Allow the blade to come to a complete stop before removing the cut pieces or making any adjustments.

Techniques for Cutting Plastic with a Circular Saw

Now that you have the right blade and safety precautions in place, let’s explore some techniques for cutting plastic with a circular saw:

1. Use a guide: To ensure straight and accurate cuts, consider using a guide or a straightedge parallel to the cut line. This will help you maintain a steady cutting path and prevent the blade from veering off course.

2. Score the plastic: For thicker plastic sheets, you can score the surface lightly with a utility knife before making the cut. This will create a groove that guides the circular saw, resulting in cleaner and smoother cuts.

3. Control the speed: Avoid using high speeds while cutting plastic. Reduce the saw’s speed to minimize friction and prevent the plastic from melting or chipping. Take your time and let the blade make gradual and controlled cuts.

4. Support the cut piece: When the cut is nearly complete, support the piece that is about to be cut off to prevent it from falling and creating an uneven cut. This will ensure clean and precise cuts from start to finish.

Cleaning and Maintaining Your Circular Saw

After successfully cutting plastic with your circular saw, it’s essential to clean and maintain the tool to ensure its longevity and performance. Here are some tips for cleaning and maintaining your circular saw:

1. Remove plastic debris: After each use, remove any plastic debris that may have accumulated on and around the blade. Use a brush or compressed air to clean the saw thoroughly.

2. Lubricate moving parts: Apply lubricating oil to the blade arbor and other moving parts to reduce friction and prevent rusting.

3. Check for damage: Regularly inspect the blade, arbor, and other components for any signs of damage or wear. Replace any worn-out or damaged parts to maintain optimal cutting performance.

The Benefits of Using a Circular Saw on Plastic

Using a circular saw on plastic offers several benefits, making it a valuable tool for certain applications. Some advantages include:

- Precision cuts: A circular saw allows for precise and clean cuts, enabling you to achieve the desired shape and dimensions for your plastic projects.

- Efficiency: Circular saws are powerful and efficient tools that can quickly cut through plastic sheets and other plastic materials.

- Versatility: With the right blade, a circular saw can cut through a wide range of plastic materials, making it suitable for various projects.

- Cost-effective: Investing in a plastic-cutting blade for your circular saw is a cost-effective option compared to purchasing specialized tools for cutting plastic.

Conclusion

Using a circular saw on plastic is possible with the right blade, techniques, and safety precautions. By choosing a plastic-cutting blade, following safety guidelines, and employing proper cutting techniques, you can achieve clean and precise cuts on plastic materials. Remember to prioritize safety, invest in a high-quality blade, and maintain your circular saw regularly for optimal performance. Now that you have the knowledge, go ahead and tackle your plastic cutting projects with confidence!

Key Takeaways: Can You Use a Circular Saw on Plastic?

- No, it is not recommended to use a circular saw on plastic.

- Using a circular saw on plastic can cause melting, chipping, and rough cuts.

- Plastic is best suited for cutting with a jigsaw or a utility knife.

- When cutting plastic, use a fine-toothed blade for cleaner cuts.

- Always wear safety goggles and gloves when working with power tools.

Frequently Asked Questions

When it comes to using a circular saw on plastic, there are a few important considerations to keep in mind. We have compiled a list of commonly asked questions to help you better understand the process and ensure your safety while working with plastic materials.

1. Is it safe to use a circular saw on plastic?

Yes, it is generally safe to use a circular saw on plastic. However, it is important to take necessary precautions to prevent any accidents or damage to the material. Make sure to use a blade specifically designed for cutting plastic, as it will have a higher tooth count and a finer tooth profile.

Additionally, always wear appropriate safety gear, including safety glasses and gloves, to protect yourself from any potential hazards. Remember to take your time and make smooth, steady cuts to minimize the risk of the plastic melting or cracking.

2. Can I use a regular wood-cutting blade on plastic?

While it is technically possible to use a regular wood-cutting blade on plastic, it is not recommended. Wood-cutting blades have a larger tooth profile and fewer teeth per inch compared to blades designed specifically for cutting plastic. This can cause the plastic to melt or chip, leading to a rough and potentially dangerous cut.

To ensure clean and precise cuts, it is best to invest in a blade specifically designed for cutting plastic. These blades are made with materials and tooth profiles that are optimized for plastic, providing smoother cuts and minimizing the risk of damage to the material.

3. What type of circular saw is best for cutting plastic?

When it comes to cutting plastic, a circular saw with a lower blade speed and a higher tooth count is generally recommended. A slower blade speed helps prevent the plastic from melting or chipping, while a higher tooth count provides a finer and cleaner cut.

If you frequently work with plastic materials, you may want to consider investing in a circular saw with variable speed control. This allows you to adjust the blade speed according to the specific plastic material you are working with, ensuring optimal cutting results.

4. Are there any particular techniques for cutting plastic with a circular saw?

Yes, there are some techniques that can help you achieve better results when cutting plastic with a circular saw. First, make sure to secure the plastic material firmly in place, either by using clamps or a workbench. This will prevent it from moving or vibrating during the cutting process.

Additionally, try to make smooth and steady cuts, without applying excessive pressure or forcing the blade. Let the saw do the work, and allow the teeth to gradually cut through the plastic. This will minimize the risk of melting or cracking and ensure a cleaner cut.

5. What are some common applications for using a circular saw on plastic?

A circular saw can be used for a variety of applications involving plastic materials. Some common examples include cutting plastic sheets or panels for construction or DIY projects, trimming plastic piping, and creating custom shapes or designs out of plastic materials.

However, it is important to note that the suitability of a circular saw for specific plastic materials may vary. Always refer to the manufacturer’s recommendations and make sure to use the appropriate blade and cutting techniques for the particular type of plastic you are working with.

Summary:

Can you use a circular saw on plastic? It’s not a good idea. The high speed and powerful blades can cause the plastic to melt or shatter, creating a safety hazard. Instead, it’s recommended to use a saw specifically designed for cutting plastic, like a jigsaw or a bandsaw. These tools have slower blade speeds and finer teeth that are better suited for cutting through plastic materials. Remember to always wear appropriate safety gear, like goggles and gloves, when working with power tools to protect yourself from any flying debris. Use caution and make sure to follow the manufacturer’s instructions for the tool you are using.

In conclusion, if you need to cut plastic, it’s best to avoid using a circular saw. Instead, opt for a saw that is specifically designed for cutting plastic materials to ensure a safer and more accurate cut. Safety should always be a top priority when working with power tools.