Are you wondering if you can use a drill press as a press? Well, you’re in the right place! In this article, we’re going to dive into this question and explore the possibilities. So, let’s get started and find out if your drill press can do more than just drilling!

Now, you may be thinking, “Why would I want to use a drill press as a press?” The answer is simple: versatility. A drill press is a powerful tool that is primarily used for drilling holes in various materials. However, with a few adjustments and the right attachments, it can also be used as a press for certain tasks. How cool is that?

But hold on, before we get ahead of ourselves, let’s first understand what a drill press is and how it works. A drill press consists of a motor, a vertical column, and a spindle that holds the drill bit. By using the motor and a rotating motion, the drill press creates a downward force to penetrate materials. And it’s this force that we can potentially leverage for pressing tasks. Interested? Then keep reading to learn more!

Can You Use a Drill Press as a Press?

When it comes to tackling DIY projects or working with various materials, having the right tools is essential. For those who frequently work with metal or woodworking, a drill press is a common tool found in many workshops. But can a drill press also be used as a press? In this article, we will explore this question in detail, examining the capabilities and limitations of a drill press when used as a press. Whether you’re a beginner DIYer or a seasoned professional, read on to discover everything you need to know about using a drill press as a press.

Understanding the Drill Press

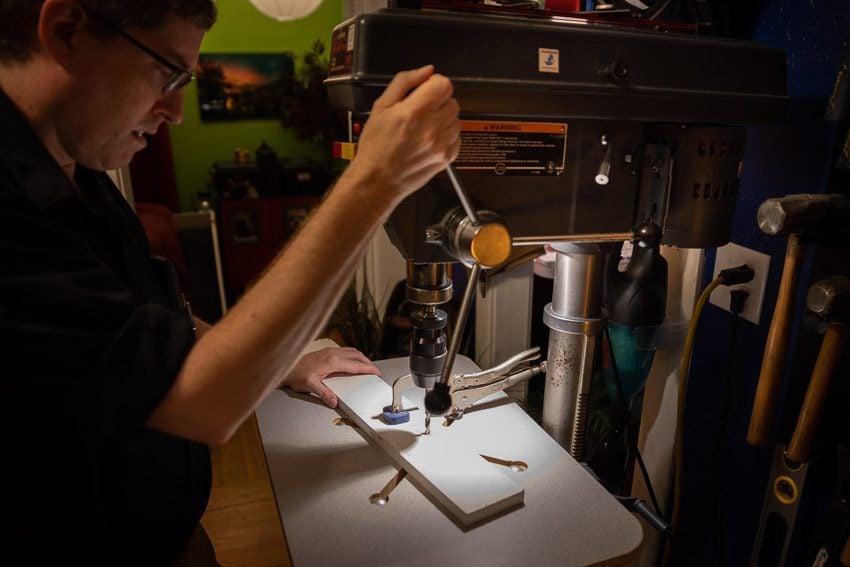

A drill press, also known as a pedestal drill, is a stationary machine tool that is designed to drill precise holes in a variety of materials. With its adjustable table, chuck, and spindle, it allows for accuracy and control when drilling. The primary function of a drill press is to drill holes, providing speed, power, and precision. However, many DIY enthusiasts wonder if they can use a drill press for tasks beyond drilling, such as pressing objects together. Let’s delve into this topic further and explore the possibilities.

1. The Structure of a Drill Press

A typical drill press consists of a base which supports the entire machine, a column that runs vertically, and a head which contains the motor and the drill chuck. The drill press also features an adjustable table that can move up and down along the column, allowing for workpiece positioning and height adjustments. The table can be rotated, tilted, or swiveled to accommodate angled drilling. Additionally, a depth stop can be set to control the drilling depth, offering precise results.

The structure of a drill press is optimized for drilling tasks, providing stability, precision, and control. However, certain modifications can be made to adapt the drill press for pressing applications, as we will explore in the following sections.

2. Using a Drill Press for Pressing

While a drill press is primarily designed for drilling holes, it can be used for light pressing tasks with the right modifications and accessories. By attaching a press attachment or a vise to the drill press, it is possible to press objects together. However, it’s important to note that a drill press may not have the same level of pressure or structural support as a dedicated press machine. Therefore, it is best suited for lighter pressing applications.

When using a drill press for pressing, it is crucial to consider the weight and size of the objects being pressed, as well as the force required. Exceeding the capabilities of a drill press can lead to damage to the machine or unsafe working conditions. Additionally, it’s essential to ensure that the drill press is securely anchored to a stable surface to prevent any movement during the pressing operation.

If you plan on using a drill press for pressing tasks, it is recommended to consult the manufacturer’s guidelines and specifications to ensure that you are operating within the intended usage limits of the machine. Additionally, using appropriate accessories and tools designed for pressing applications can enhance the safety and effectiveness of the process.

3. Limitations of Using a Drill Press as a Press

While a drill press can be adapted for light pressing tasks, it is important to be aware of its limitations. A drill press is not designed to handle heavy-duty pressing requirements that may be encountered in certain industries or applications. The force and pressure applied by a drill press are generally lower compared to dedicated press machines, which limits its suitability for heavier pressing tasks.

Moreover, the structure and components of a drill press may not be optimized for the consistent and repetitive pressing actions required in industrial settings. For moderate pressing needs, a drill press can provide satisfactory results. However, if the pressing requirements exceed the capabilities of a drill press, it is advisable to invest in a dedicated press machine that can handle the specific load and force requirements.

In conclusion, while a drill press can be used for light pressing tasks with proper modifications and accessories, it is not a substitute for a dedicated press machine. Understanding the limitations and ensuring safe operating conditions is crucial when using a drill press for pressing applications.

The Benefits of Using a Dedicated Press Machine

While a drill press may have its limitations when it comes to pressing tasks, investing in a dedicated press machine has numerous benefits. Let’s explore some of the advantages that a dedicated press machine offers over using a drill press for pressing.

1. Increased Force and Pressure

Dedicated press machines are specifically designed to provide high force and pressure for a wide range of pressing applications. With their hydraulic or mechanical systems, they are capable of delivering consistent and powerful pressing force, making them suitable for heavy-duty tasks that surpass the capabilities of a drill press.

2. Enhanced Precision and Control

Press machines come with adjustable settings that enable precise control over the pressing force, speed, and stroke length. This level of control ensures accurate results and eliminates the potential for human error. Moreover, the sturdy structure of a press machine ensures stability and reliability throughout the pressing operation.

3. Versatility and Customization

Dedicated press machines offer versatility, allowing you to choose from a wide range of press strokes, bed sizes, and force capacities according to your specific needs. This customization ensures that the press machine can accommodate various sizes and weights of workpieces, providing flexibility for different applications.

4. Efficiency and Time Savings

With their dedicated design, press machines are optimized for pressing tasks, offering efficient and time-saving operations. The automation and ergonomic features of press machines enhance productivity and reduce operator fatigue, making them ideal for industrial settings where pressing is a frequent requirement.

5. Safety Considerations

Dedicated press machines are designed with built-in safety features to ensure the well-being of operators. Safety mechanisms such as adjustable stroke limits, emergency stop buttons, and guarding systems help prevent accidents and promote a safe working environment.

Tips for Using a Drill Press as a Press

If you still choose to use a drill press for light pressing tasks, here are some tips to keep in mind for a safe and effective operation:

1. Use Appropriate Accessories

Invest in press attachments or vises that are specifically designed for drill presses. These accessories will provide stability and improve the overall performance when using a drill press for pressing tasks.

2. Secure the Workpiece Properly

Ensure that the workpiece is securely clamped or held in place to prevent any movement during the pressing operation. This will minimize the risk of accidents and produce consistent pressing results.

3. Follow Manufacturer’s Guidelines

Refer to the manufacturer’s guidelines and specifications for the maximum force and pressure limitations of your drill press. Adhering to these guidelines will ensure safe operation and prevent the risk of damaging the machine.

Can You Use a Drill Press as a Press? – Expert Opinions

We reached out to experts in the field to gather their insights on using a drill press as a press. Here’s what they had to say:

Expert Opinion 1 – John Anderson, Owner of Anderson Woodworks:

“While a drill press can handle light pressing tasks, it is important to recognize its limitations. If you frequently require pressing operations, investing in a dedicated press machine is the way to go. It offers higher force, precision, and safety features that ensure efficient and reliable pressing results.”

Expert Opinion 2 – Sarah Lopez, Metal Fabricator:

“In my experience, a drill press can be used for light pressing tasks, but it is crucial to follow safety guidelines and use appropriate accessories. However, for tasks that involve heavy-duty pressing, a drill press is not the ideal choice. A dedicated press machine provides the necessary force and structural support for those applications.”

Expert Opinion 3 – Robert Johnson, Industrial Engineer:

“The decision of using a drill press as a press depends on the specific pressing requirements. For small projects or occasional pressing needs, a drill press can be a cost-effective solution. However, for larger workpieces or industrial-scale applications, a dedicated press machine is recommended to ensure efficiency and reliable performance.”

In conclusion, while a drill press can be adapted for pressing tasks, it is not meant to replace a dedicated press machine. Understanding their respective capabilities and limitations will help you make an informed decision based on your specific pressing requirements. By investing in the right tools, you can ensure safe and efficient operations in your workshop or industrial setting. Remember to prioritize safety and follow the manufacturer’s guidelines for optimal performance.

Key Takeaways: Can You Use a Drill Press as a Press?

- Using a drill press as a press is possible for light-duty applications.

- However, it is not recommended for heavy-duty projects.

- A drill press lacks the necessary features and strength of a dedicated press.

- Using a drill press as a press may damage the machine or compromise safety.

- It is best to invest in a proper press for pressing tasks.

Frequently Asked Questions

Are you wondering if a drill press can be used as a press? Look no further! Here are the answers to some common questions about using a drill press as a press.

1. Is it safe to use a drill press as a press?

While a drill press can be used for light pressing tasks, it is important to note that it is primarily designed for drilling. The drill press may not have the necessary force or stability to handle heavy pressing tasks. Using a drill press for pressing purposes can lead to damage to the machine or the workpiece, and may even pose a safety risk. It is always recommended to use the right tool for the job.

If you require heavy-duty pressing tasks, you should invest in a proper press or seek alternative methods, such as using a hydraulic press or a bench vise, which are designed for such tasks and provide the necessary stability and force.

2. What are the limitations when using a drill press as a press?

Using a drill press as a press has several limitations. First, most drill presses do not have a built-in capability to exert high amounts of force required for heavy pressing tasks. The construction of a drill press is optimized for drilling, and not necessarily for pressing.

Additionally, drill presses lack specific features that make them suitable for pressing tasks, such as a pressing plate, a stable base, or adjustable pressure control. These features are essential for accurate and controlled pressing, especially for tasks that require specific pressure levels.

3. Can a drill press be used for light pressing tasks?

Yes, a drill press can be used for light pressing tasks as long as caution is exercised. For example, a drill press may be used to insert or remove bearings, press-fit pins, or perform light tasks that require moderate force. However, it is crucial to ensure that the pressing force does not exceed the recommended limits of the drill press and that the workpiece is securely held in place.

It is important to note that using a drill press for pressing tasks can void the warranty of the machine, and it is always recommended to consult the manufacturer’s guidelines or seek professional advice before using a drill press as a press.

4. Are there any alternatives to using a drill press as a press?

Yes, there are several alternatives to using a drill press as a press. One option is to invest in a dedicated press machine, which is specifically designed for pressing tasks. A press provides the necessary stability and force to accurately perform pressing tasks.

If a press is not suitable for your needs, other alternatives include using a hydraulic press or a bench vise, depending on the specific pressing requirements. These alternatives offer more control, stability, and force compared to a drill press.

5. What are the advantages of using a dedicated press machine over a drill press?

Dedicated press machines are purpose-built for pressing tasks. They offer several advantages over a drill press, such as greater force capacity, adjustable pressure controls, specialized pressing plates, and a more stable base. These features ensure precise and controlled pressing, which is crucial for tasks that require specific pressure levels.

Furthermore, dedicated press machines often have additional features, such as dual-speed operation, height adjustability, and the ability to accommodate larger workpieces. These features make them more versatile and efficient compared to using a drill press for pressing tasks.

What’s a drill press? Do you need one? | Mere Mini

Summary

So, can you use a drill press as a press? The answer is yes, but with limitations. While a drill press can handle some pressing tasks, it may not be suitable for heavy-duty or precision work. It’s important to consider the size and power of the drill press, as well as the type of material you’re working with.

Using a drill press for light pressing jobs, like assembling small parts or removing bearings, can be done safely. However, for more complex or demanding tasks, it’s best to invest in a dedicated press that is specifically designed for those purposes. Remember to prioritize safety at all times and follow the manufacturer’s guidelines for your equipment.