Looking to transform your drill press into a versatile woodworking tool? Well, you may be wondering, can you use a drill press as a spindle sander? Let’s dive in and explore this fascinating possibility!

If you’ve got a drill press lying around, you might be excited to discover that with a few modifications, it can indeed be used as a spindle sander. But what exactly is a spindle sander? It’s a tool specifically designed to smooth and shape curved edges and contours on wood pieces.

Now, before we get too carried away, let’s unravel the details of how to transform your trusty drill press into a handy spindle sander. Ready to unleash your creativity and take your woodworking projects to the next level? Let’s get started!

Looking for an alternative to a spindle sander? While you can’t directly use a drill press as a spindle sander, there are workarounds to achieve similar results. Attach a sanding drum to your drill press and adjust the speed to match the required sanding speed. Ensure you have proper safety precautions in place and test on scrap material first. Remember, a drill press is not designed for sanding, so proceed with caution.

Can You Use a Drill Press as a Spindle Sander?

When it comes to woodworking, having the right tools for the job can make a world of difference. One question that often arises is whether a drill press can be used as a spindle sander. While both tools have their own unique purposes, it is possible to use a drill press as a makeshift spindle sander under certain conditions. In this article, we will explore the possibilities, benefits, and limitations of using a drill press as a spindle sander, and provide tips for achieving the best results.

Understanding the Differences between a Drill Press and a Spindle Sander

A drill press is a versatile tool used primarily for drilling holes accurately and consistently. It consists of a motor, a spindle, and a chuck that holds various drill bits. On the other hand, a spindle sander is specifically designed for sanding curved, contoured, or irregular surfaces. It features a spindle that holds sanding sleeves or drums of various sizes, allowing for precise sanding and shaping.

While a drill press can rotate the workpiece and perform sanding with sanding drums attached to the chuck, it lacks some crucial features when compared to a dedicated spindle sander. For example, a spindle sander often has a tilting table, which enables sanding at different angles. The oscillating action of a spindle sander also prevents the accumulation of heat on the workpiece, reducing the risk of burning the wood. Additionally, a spindle sander usually has a larger sanding surface area, providing better support for larger workpieces.

The Benefits of Using a Drill Press as a Spindle Sander

Despite the limitations, there are several benefits to using a drill press as a spindle sander. Firstly, it allows you to utilize a tool you already have in your workshop for additional purposes, saving both space and money. Secondly, a drill press typically has a powerful motor, resulting in higher sanding speeds compared to handheld spindle sanders. This can be advantageous when working with harder or denser materials that require more aggressive sanding. Lastly, a drill press provides a stable and precise platform, ensuring accurate sanding and reducing the risk of operator errors.

To optimize the performance of a drill press as a spindle sander, here are a few tips to keep in mind:

- Use the lowest possible speed setting on your drill press. This will help prevent the sanding drums from overheating and reduce the risk of damaging the workpiece.

- Ensure that the sanding drums are securely mounted in the chuck and properly centered. This will minimize vibration and result in smoother sanding.

- Consider using lightweight, softer sanding sleeves or drums to reduce the strain on the drill press motor and prolong its lifespan.

- Take frequent breaks to allow the drill press to cool down and prevent overheating. This is especially important when working on large or time-consuming projects.

- Always wear appropriate personal protective equipment, such as safety goggles and a dust mask, to protect yourself from flying debris and dust.

Alternatives to Using a Drill Press as a Spindle Sander

If you find yourself in a situation where you need a spindle sander but don’t have access to one, there are a few alternatives you can consider. One option is to use a handheld spindle sander, which is a compact and portable tool designed specifically for sanding curved surfaces. Another option is to use sanding drums or flap sanding wheels attached to a handheld power drill. While these alternatives may not provide the same level of precision and versatility as a dedicated spindle sander, they can still produce satisfactory results for smaller projects or occasional use.

Conclusion

While a drill press can be used as a spindle sander in certain situations, it is important to recognize the limitations and potential risks involved. A dedicated spindle sander offers superior capabilities and safety features that cannot be fully replicated by a drill press. However, with proper precautions and techniques, a drill press can still serve as a viable alternative for basic sanding tasks. Ultimately, the decision of whether to use a drill press as a spindle sander will depend on the specific requirements of your project, the available tools, and your comfort level with improvisation.

Key Takeaways: Can You Use a Drill Press as a Spindle Sander?

- 1. A drill press can be used as a makeshift spindle sander.

- 2. It is important to use the right attachments and sanding drums for the drill press.

- 3. The drill press should be set to a low speed for sanding tasks.

- 4. It may not be as efficient as a dedicated spindle sander, but it can still get the job done.

- 5. Make sure to take necessary safety precautions and wear protective gear when using a drill press as a spindle sander.

## Frequently Asked Questions

### Can a drill press be used as a spindle sander?

**Question 1: Is it possible to use a drill press as a spindle sander?**

Answer: While it may seem tempting to use a drill press as a spindle sander, it is not recommended. A drill press and a spindle sander are two different tools designed for specific tasks. A drill press is primarily used for drilling holes, while a spindle sander is designed for sanding curved edges and smoothing out surfaces. Trying to use a drill press as a spindle sander can result in an ineffective and potentially dangerous operation.

Using a drill press as a spindle sander can be dangerous because spindle sanders are equipped with oscillating drums that move up and down. This motion helps to evenly distribute the sanding action across the surface. A drill press, on the other hand, does not have this oscillating feature, which can lead to uneven sanding and potentially damage the workpiece.

**Question 2: What are the risks of using a drill press as a spindle sander?**

Answer: Using a drill press as a spindle sander can pose several risks. As mentioned earlier, a drill press lacks the oscillating motion that is crucial for sanding curved edges and achieving even results. This can leave unsightly sanding marks and uneven surfaces on your workpiece. Moreover, the sharp edges of the drilling spindle in a drill press can inadvertently dig into the workpiece, causing damage and ruining your project.

Additionally, drill presses are designed to withstand the downward force exerted during drilling. The bearings and mechanisms of a drill press are not built to handle the horizontal forces involved in sanding. This can lead to premature wear and tear on your drill press, reducing its lifespan and compromising its drilling capabilities. It’s best to invest in a dedicated spindle sander for optimal sanding results and to protect the integrity of your drill press.

**Question 3: What is the purpose of a spindle sander?**

Answer: A spindle sander is a specialized tool used for sanding curved edges, smoothing out surfaces, and removing material from contoured workpieces. It features a drum or spindle that rotates and oscillates vertically, giving it a finer sanding action compared to other sanding tools. The oscillating motion helps to prevent sanding marks and produces a smoother finish.

The primary purpose of a spindle sander is to sand and shape curves, such as those found in chair legs, table edges, or decorative woodwork. Its drum size and interchangeable sleeves allow for sanding operations of various diameters, making it versatile for different projects. Additionally, some spindle sanders are equipped with tilting tables, which enable sanding at angles, further expanding their functionality.

**Question 4: What are the benefits of using a dedicated spindle sander?**

Answer: Using a dedicated spindle sander offers several benefits over trying to use a drill press as a substitute. Firstly, dedicated spindle sanders have oscillating drums that provide a more even sanding action. This results in smoother finishes and reduces the risk of leaving sanding marks on your workpiece.

Secondly, spindle sanders often have tilting tables that allow for sanding at different angles, providing greater versatility in shaping and smoothing curved edges. Adjusting the table angle enables you to achieve precise beveling or chamfering effects on your workpiece.

Lastly, using a dedicated spindle sander preserves the integrity of your drill press. By using the right tool for each job, you reduce strain on your drill press and extend its lifespan. This eliminates the risks of premature wear and tear and ensures that you have a reliable tool for drilling tasks.

**Question 5: Are there any alternatives to a spindle sander?**

Answer: If you don’t have access to a spindle sander or prefer not to invest in one, there are alternative methods you can use to achieve similar results. One option is to use different sanding attachments on a handheld rotary tool, such as a Dremel. These attachments can provide precise sanding capabilities for smaller and more intricate workpieces.

Another alternative is using sandpaper wrapped around various-sized dowels, allowing you to manually sand contours and curved edges. This method requires more effort and precision but can still yield satisfactory results, especially for smaller projects.

It’s important to note that while these alternatives can work, they may not provide the same level of convenience and efficiency as a dedicated spindle sander. However, they can be suitable options if you’re working on a limited budget or have specific size limitations for your project.

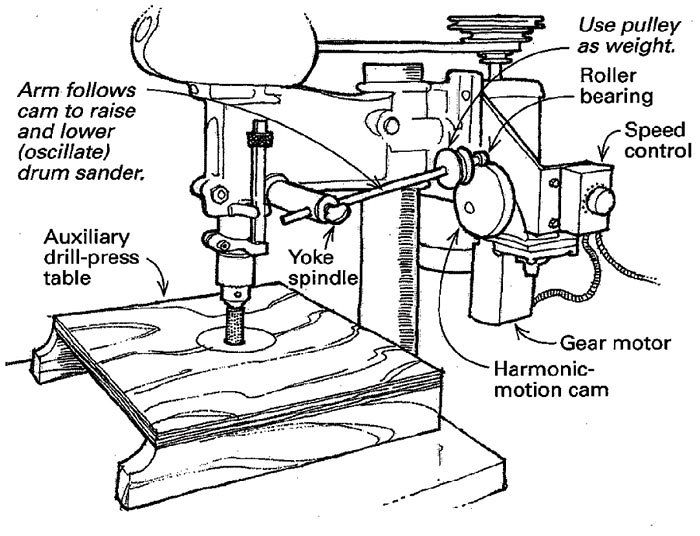

How To Turn Your Drill Press Into a Spindle Sander

Summary

Using a drill press as a spindle sander can be dangerous and ineffective. The drill press lacks the necessary features to provide precise sanding and may cause the material to splinter. It’s best to invest in a dedicated spindle sander for better results and safety.