If you’ve ever wondered, “Can you use a lathe for milling?” Well, you’re in the right place! Whether you’re a budding DIY enthusiast or just curious about machining processes, this article will give you the lowdown on using a lathe for milling. So grab your safety goggles and let’s dive in!

When it comes to machining, a lathe is a versatile tool that primarily rotates the workpiece. But did you know that with a few modifications, a lathe can also be used for milling? That’s right! By attaching a milling fixture to the lathe’s toolpost and using appropriate cutting tools, you can achieve some milling operations on your trusty lathe.

So why would you want to use a lathe for milling? Well, it offers a cost-effective solution for small-scale milling tasks and saves valuable workspace. Plus, if you already have a lathe in your workshop, it’s a convenient way to expand your machining capabilities without investing in a separate milling machine. Exciting, isn’t it? Let’s explore further!

Can You Use a Lathe for Milling? Exploring the Possibilities

Introduction to Using a Lathe for Milling

When it comes to machining operations, lathes and milling machines are two of the most commonly used tools. While each has its specific functions, there is often curiosity around whether a lathe can be utilized for milling purposes. In this article, we will delve into the topic of using a lathe for milling and explore the possibilities it presents. Whether you’re a hobbyist or a professional machinist, understanding the potential of your lathe can open up new avenues for creativity and efficiency in your machining projects.

Understanding the Basics of a Lathe

Before we explore the feasibility of using a lathe for milling tasks, it’s essential to understand the basic workings of a lathe. A lathe is a machine tool that rotates a workpiece on its axis while using various cutting tools to shape, drill, or turn the workpiece into the desired shape. The cutting tools are typically fixed onto the tool post and move in different directions along the workpiece to achieve the desired result. Lathes are commonly used for tasks such as turning, facing, grooving, threading, and tapering.

One of the distinguishing features of a lathe is its ability to rotate the workpiece, allowing for intricate and precise cuts. However, unlike milling machines, lathes do not have the capability to move the cutting tool in multiple axes simultaneously. This limitation raises the question of whether a lathe can be effectively used for milling operations.

The Challenges of Using a Lathe for Milling

While a lathe can be adapted for certain milling tasks, there are several challenges that come with utilizing it as a milling machine. One of the primary hurdles is the absence of a vertical movement mechanism for the cutting tool. In milling machines, the cutting tool is able to move in multiple axes, including up and down, allowing for the creation of slots, pockets, and complex shapes. A lathe, on the other hand, lacks this vertical movement, making it difficult to achieve such features.

Another challenge posed by using a lathe for milling is the lack of a suitable work-holding mechanism. Milling machines are equipped with vices, clamps, or fixtures that securely hold the workpiece in place during the cutting process. Lathes typically rely on chucks or collets to grip the workpiece, which may not provide the same level of stability required for milling operations.

Despite these challenges, it is possible to perform certain milling tasks on a lathe with the right modifications and techniques. Machinists have developed various methods to overcome these limitations and achieve acceptable milling results using a lathe. Let’s delve into some of these approaches and explore the possibilities further.

Modifying a Lathe for Milling: Techniques and Tips

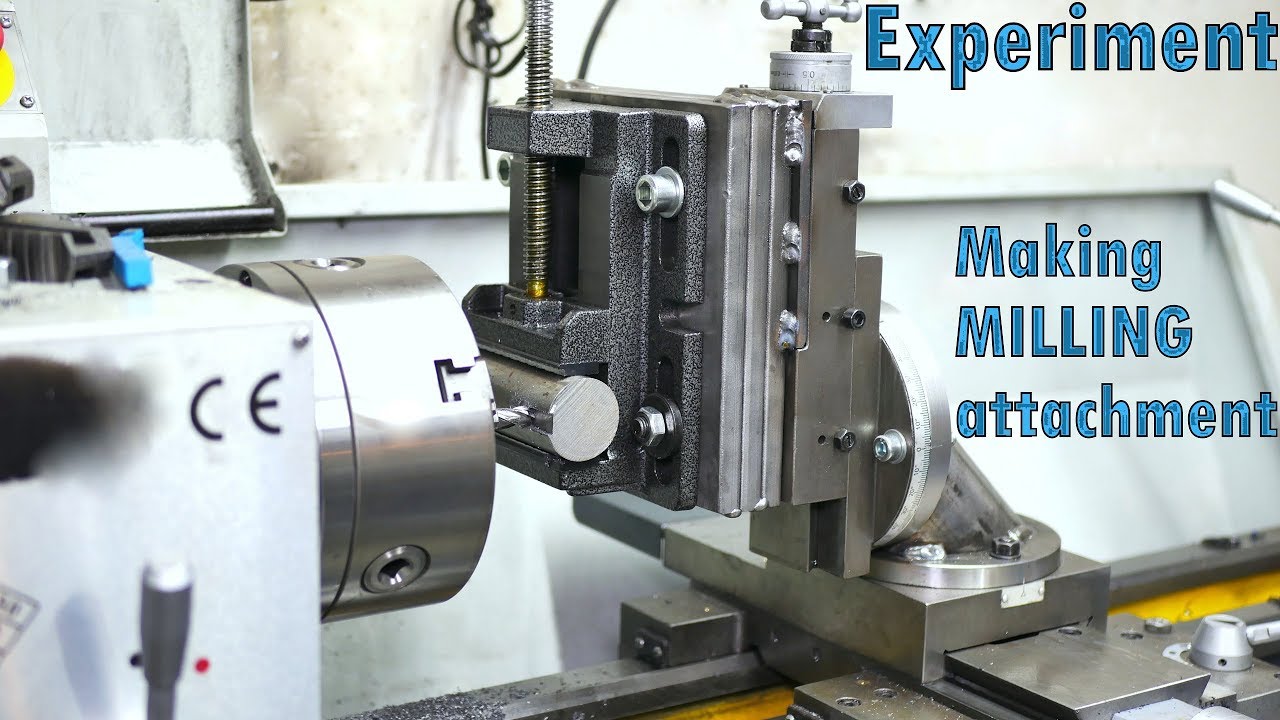

While a lathe may not be designed specifically for milling, there are modifications that can be made to enhance its milling capabilities. One common approach is to attach a milling attachment or a milling slide to the lathe’s tool post. These attachments allow for limited movement in the vertical and horizontal axes, enabling the execution of basic milling tasks.

Another technique involves utilizing a rotary table in conjunction with the lathe. A rotary table can be mounted on the lathe’s cross slide, providing the necessary rotational movement for milling operations. The combination of the lathe’s rotating capability and the rotary table’s movement can result in more intricate milling tasks being performed.

It’s important to note that these modifications and techniques have their limitations and may not match the precision and versatility of a dedicated milling machine. However, they can be a suitable alternative for small-scale milling projects or situations where access to a milling machine is limited.

Conclusion

While a lathe is primarily designed for turning operations, it can be adapted for certain milling tasks with the right modifications and techniques. However, it’s important to be aware of the limitations and challenges involved in using a lathe for milling. For more complex milling operations requiring precise movements in multiple axes, a dedicated milling machine is often the better choice. Nonetheless, with the appropriate modifications and skillful execution, a lathe can serve as a viable option for certain milling projects. So, whether you’re exploring the potential of your existing lathe or considering investing in a milling machine, understanding the possibilities and limitations of each tool will empower you to make informed decisions and enhance your machining capabilities.

Key Takeaways: Can You Use a Lathe for Milling?

- While a lathe is primarily designed for turning operations, it is possible to use it for milling certain materials.

- However, milling with a lathe is not as efficient or precise as using an actual milling machine.

- Milling on a lathe requires special attachments and tools, such as a milling attachment and a milling cutter.

- Using a lathe for milling can be a good option for small, simple milling tasks, but it is not recommended for complex or high-precision milling projects.

- If you are looking to perform milling operations regularly, it is advisable to invest in a dedicated milling machine for better results.

# Frequently Asked Questions

## Can a lathe be used for milling?

### Answer:

While a lathe is primarily designed for turning cylindrical pieces, it can be used for some milling functions. This process, known as lathe milling, involves mounting a milling cutter in the lathe chuck and using the lathe’s cross-slide and compound rest to move the workpiece. However, it’s important to note that a lathe is not designed for heavy milling operations and may have limitations in terms of speed, precision, and cutting depth.

Lathe milling is more suitable for lighter milling tasks, such as creating grooves, slots, or flat surfaces on small workpieces. It can be a useful technique if you don’t have access to a dedicated milling machine or if you need to perform simple milling operations occasionally. However, for complex milling tasks or high-precision work, a dedicated milling machine is recommended.

### Answer:

Yes, a lathe can be used for certain milling tasks. Lathe milling, also known as using a lathe for milling, involves attaching a milling cutter to the lathe chuck and using the lathe’s controls to move the workpiece. While a lathe is primarily designed for turning operations, this technique can be used for light milling work.

It’s important to understand that a lathe is not as versatile or precise as a dedicated milling machine. The cutting speed, depth, and accuracy may be limited when using a lathe for milling. For more complex or precise milling tasks, it is recommended to use a dedicated milling machine. However, if you have a lathe and need to perform simple milling operations, this technique can be a viable option.

Summary

So, can you use a lathe for milling? Well, technically, it is possible, but it’s not ideal. Lathes are designed for turning and shaping cylindrical objects, while mills are better suited for cutting flat surfaces and creating complex shapes. While you may be able to make some simple milling cuts on a lathe, it lacks the necessary features and capabilities of a dedicated milling machine. If you are serious about milling, it’s best to invest in a proper milling machine to ensure accurate and efficient results.

Additionally, using a lathe for milling can be dangerous if not done properly. The lack of stability and control can lead to unpredictable outcomes, putting you at risk of injury. It’s always important to prioritize safety and use the right tool for the job. So, while a lathe can provide a temporary solution for basic milling tasks, it’s important to consider the limitations and potential risks involved.