If you’re wondering, “can you use a shop vac on a table saw?” – you’ve come to the right place! Let’s dive right in and explore this question.

Now, picture this: you’re in your workshop, ready to tackle a woodworking project. The table saw is buzzing with power, and you want to keep things neat and tidy. But can you connect a shop vac to your table saw?

Join me on this journey as we uncover the answer to this query and discover the best way to keep your workspace clean and sawdust-free. So, buckle up and let’s get started!

Using a shop vac on a table saw is a common practice for dust collection. By attaching the shop vac to the table saw’s dust port, you can effectively minimize the mess created by sawdust. It’s important to make sure the shop vac has sufficient suction power and a suitable filter to handle the fine dust particles produced by the table saw. Regular maintenance and cleaning of the shop vac are also necessary to ensure optimal performance.

Can You Use a Shop Vac on a Table Saw?

Table saws are a staple in many woodworking shops, and keeping the work area clean is crucial for safety and efficiency. One common question that arises is whether a shop vac can be used to collect dust and debris from a table saw. In this article, we will explore the compatibility of shop vacuums with table saws, the benefits and drawbacks of using a shop vac, and tips for effective dust collection.

Why Use a Shop Vac on a Table Saw?

When it comes to dust collection on a table saw, a shop vac can be a handy tool. Here are a few reasons why many woodworkers prefer using a shop vac:

- Efficient Dust Removal: Shop vacuums are designed to remove dust and debris effectively, which is essential when working with a table saw that generates a significant amount of sawdust. By connecting a shop vac to your table saw, you can keep your work area clean and prevent dust from accumulating on your tools or entering your lungs.

- Portability: Shop vacuums are typically compact and portable, making it easy to move them around your workspace. This versatility allows you to position the vacuum in the most convenient location to capture the dust generated by your table saw.

- Compatibility: Most shop vacuums come with attachments and accessories that can be connected to different tools, including table saws. This compatibility ensures a hassle-free setup and efficient dust collection.

The Benefits of Using a Shop Vac on a Table Saw

Utilizing a shop vac on your table saw offers several advantages:

- Cleaner Work Environment: The primary benefit of using a shop vac on a table saw is maintaining a clean and dust-free workspace. This not only improves visibility but also reduces the risk of accidents caused by slipping on sawdust or improper tool operation due to obscured vision.

- Improved Efficiency: With a shop vac connected to your table saw, you spend less time manually sweeping or brushing away sawdust. This allows you to focus on your woodworking projects and increases overall efficiency in the workshop.

- Health and Safety: A shop vac effectively captures sawdust and other airborne particles, preventing them from being inhaled. This is important for protecting your respiratory health and reducing the risk of conditions such as asthma or lung-related issues.

The Drawbacks of Using a Shop Vac on a Table Saw

While shop vacs can be beneficial for dust collection on a table saw, there are a few drawbacks to consider:

- Limited Capacity: Shop vacuums generally have smaller capacities compared to dedicated dust collectors. This means you may need to empty the vacuum more frequently, especially when working on larger projects that produce a significant amount of sawdust.

- Noisy Operation: Shop vacuums can be quite loud, which can be distracting and potentially harmful to your hearing. Using hearing protection when working with a shop vac is recommended to reduce the risk of hearing damage.

- Potential Clogging: Depending on the size and power of your shop vacuum, it may be more prone to clogging when dealing with larger wood chips or debris. Regular maintenance and cleaning of the vacuum are essential to ensure optimal performance.

Tips for Using a Shop Vac on a Table Saw

To maximize the effectiveness of a shop vac for dust collection on a table saw, consider the following tips:

- Invest in a High-Quality Shop Vac: Consider purchasing a shop vacuum specifically designed for woodworking applications. These vacuums often have more robust filtration systems to capture fine dust particles and minimize clogging.

- Use Proper Attachments and Accessories: Ensure that you have the appropriate attachments and accessories to connect your shop vac to the table saw. This may include adapters or specialized attachments designed for table saw dust collection ports.

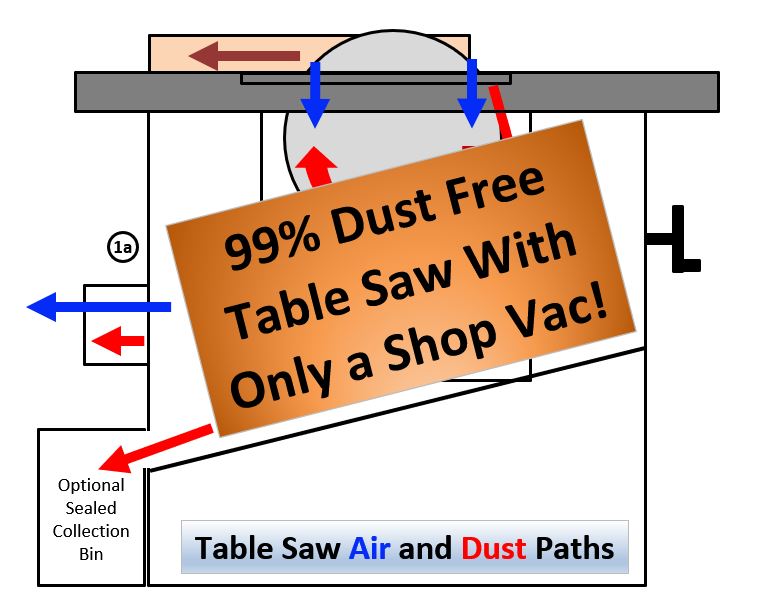

- Position the Vacuum Strategically: Place the shop vac near the area where the majority of dust is generated, usually at the rear or under the table saw. This helps to capture the dust at its source and prevent it from dispersing into the air.

- Regularly Empty and Clean the Shop Vac: Empty the shop vac and clean the filters regularly to maintain optimal performance. Clogged filters can hinder the suction power and reduce dust collection efficiency.

- Consider Supplementing with Overhead Collection: In addition to using a shop vac, you may also want to install an overhead dust collection system for even better dust control. This can be especially beneficial for larger and more powerful table saws.

Summary

Using a shop vac on a table saw can be a practical and effective way to collect dust and debris in the woodworking workshop. While shop vacuums offer benefits such as efficient dust removal and portability, they also have limitations, including limited capacity and potential clogging. By following the tips mentioned above, you can maximize the efficiency of a shop vac on your table saw and maintain a cleaner and safer work environment. Remember to prioritize your health and safety by wearing appropriate protective gear and regularly maintaining your shop vacuum for optimal performance.

Key Takeaways – Can You Use a Shop Vac on a Table Saw?

- It is not recommended to use a shop vac directly on a table saw.

- A shop vac may not have enough power to effectively remove sawdust from a table saw.

- Using a shop vac on a table saw can potentially damage the motor or other components of the vacuum.

- It is safer to use a dust collection system specifically designed for table saws.

- Investing in a proper dust collection system helps to maintain a clean and safe work environment.

Frequently Asked Questions

When it comes to woodworking and cleanup, using the right equipment is important. Here are some common questions about using a shop vac on a table saw.

1. Can a shop vac be used to collect sawdust from a table saw?

Absolutely! A shop vac can be a great tool for collecting sawdust from a table saw. It has a strong suction power that can effectively pull in the sawdust and keep your workspace clean. Just make sure to use a vacuum with a fine dust filter to prevent the dust from circulating back into the air.

Additionally, you may need to attach a dust collection attachment to your table saw to connect it to the shop vac. This will help direct the sawdust into the vacuum and ensure efficient cleanup.

2. Is it safe to use a shop vac near a table saw?

Yes, it is generally safe to use a shop vac near a table saw, but there are a few precautions to keep in mind. Make sure the shop vac is positioned in a stable location, away from the table saw’s cutting area to prevent it from being accidentally knocked over.

Moreover, always check that the power cords of the shop vac and the table saw are properly secured and out of the way to avoid any tripping hazards. Also, be mindful of any loose clothing or accessories that may get caught by the saw while working.

3. Can a shop vac replace a dust collector for a table saw?

While using a shop vac for collecting sawdust is effective, it may not completely replace a dedicated dust collector for your table saw. A shop vac is designed for smaller, portable applications and may not have the capacity to handle large amounts of sawdust generated by a table saw.

If you frequently use your table saw and generate a significant amount of sawdust, investing in a dust collector specifically designed for table saws would be more ideal. It will have a higher capacity and better filtration system, resulting in more efficient dust collection and cleaner air in your workshop.

4. What should I consider when using a shop vac on a table saw?

When using a shop vac on a table saw, consider the size and type of shop vac you are using. A larger capacity shop vac will allow you to collect more sawdust without needing to empty it frequently.

Additionally, check the compatibility of your shop vac with the table saw dust collection system. Some table saws may require specific adapters or attachments to connect to a shop vac, so ensure you have the necessary equipment for a seamless setup.

5. How often should I clean the shop vac filter when using it with a table saw?

The frequency of cleaning the shop vac filter will depend on the amount of sawdust being collected. It’s a good practice to check the filter regularly during use. If you notice a significant reduction in suction power or if the filter becomes visibly clogged, it’s time to clean it.

Cleaning the filter can be as simple as removing it from the shop vac and tapping or brushing off the accumulated dust. If the filter is in poor condition or cannot be cleaned effectively, consider replacing it to ensure optimal performance.

Attach a Table Saw to Your Shop Vac Dust Collection System

Summary

Can you use a shop vac on a table saw? The answer is no. Using a shop vac on a table saw can lead to serious safety hazards.

A shop vac is not designed to handle large amounts of sawdust produced by a table saw. It may not have enough power to effectively collect the dust, which can clog the vacuum and cause it to overheat. This can damage the vacuum and potentially start a fire.

Instead, it is recommended to use a dust collection system specifically designed for table saws. These systems are more powerful and have efficient dust collection bags or filters to safely handle the large volume of sawdust produced. Always prioritize safety and use the right equipment for the job.