Can you use a table saw for metal? If you’re curious about this, you’ve come to the right place! In this article, we’ll explore the possibilities and limitations of using a table saw for cutting metal. So, whether you’re a budding DIY enthusiast or just want to know more, let’s dive in!

Now, you might be wondering, why would anyone want to use a table saw for metal? Well, table saws are incredibly versatile tools that excel at cutting through wood. They have a powerful motor and a spinning blade that makes quick work of various woodworking projects. But when it comes to cutting metal, things can get a bit tricky.

Before we jump into the details, let’s address the big question straight away: Can you use a table saw for cutting metal? The short answer is yes, with some caveats. While a table saw can technically cut through certain types of metal, it’s not the ideal tool for the job. So, let’s explore why and what alternatives you have. Let’s get started!

While table saws are primarily designed for wood, it’s not recommended to use them for cutting metal. Metal cutting requires specialized tools like a metal cutting band saw or a circular saw with a metal-cutting blade. These tools have the power and appropriate safety features to handle the unique demands of metal cutting. Attempting to cut metal on a table saw can damage the saw, increase the risk of injury, and lead to poor quality cuts. Always use the right tool for the job to ensure safety and achieve optimal results.

Can You Use a Table Saw for Metal?

Table saws are a versatile tool commonly used for woodworking projects. However, many people wonder if they can also be used to cut metal. In this article, we will explore the possibility of using a table saw for metal and discuss the safety considerations, limitations, and alternatives.

1. Can You Cut Metal with a Table Saw?

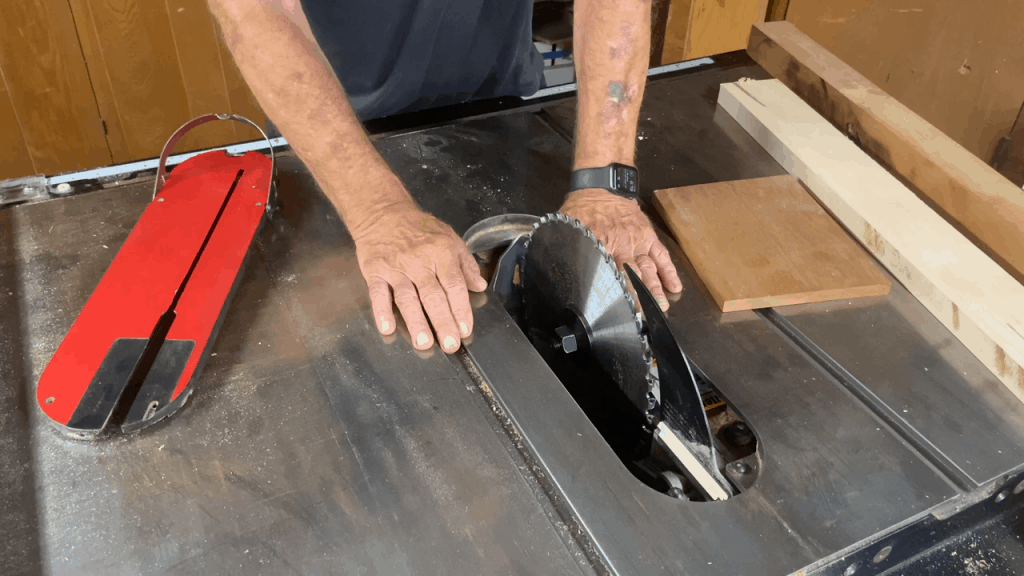

A table saw can be used to cut thin sheets of non-ferrous metals such as aluminum, brass, and copper. However, it is not recommended to use a regular table saw for cutting ferrous metals like steel or iron, as they are much denser and require specialized equipment. When cutting metal on a table saw, it is important to use the appropriate blade, such as a carbide-tipped blade designed for cutting non-ferrous metals.

Additionally, it is crucial to take extra safety precautions when cutting metal on a table saw. Metal chips and sparks can be hazardous, so wearing protective gear like safety goggles, gloves, and a face shield is essential. It is also recommended to use a metal-cutting lubricant to reduce heat and friction during the cutting process.

While a table saw can be used to cut thin sheets of non-ferrous metals, it is important to note that it may not provide the same level of precision and control as specialized metal-cutting tools. For more accurate and efficient metal cutting, it is recommended to use tools like a metal-cutting bandsaw or a plasma cutter.

2. Safety Considerations

When using a table saw to cut metal, safety should be the top priority. Here are some important safety considerations:

– Always wear appropriate safety gear, including safety goggles, gloves, and a face shield, to protect against metal chips and sparks.

– Use a carbide-tipped blade specifically designed for cutting non-ferrous metals.

– Install an appropriate blade guard to prevent accidental contact with the blade and to contain chips and sparks.

– Securely clamp the metal sheet to the table saw’s fence to ensure stability and accuracy during cutting.

– Use a metal-cutting lubricant to reduce heat and friction and to prolong the lifespan of the blade.

3. Limitations of Using a Table Saw for Metal

While a table saw can be used to cut thin sheets of non-ferrous metals, it does have some limitations:

– Thick or dense metals, such as steel or iron, cannot be cut effectively with a regular table saw. Specialized metal-cutting tools like bandsaws or plasma cutters are more suitable for these materials.

– Table saws are designed primarily for woodworking applications, and their cutting speed and power may not be optimized for cutting metal.

– The lack of a coolant system on a table saw can make it difficult to dissipate heat generated during the cutting process, which may cause the blade to wear out more quickly.

4. Alternatives for Cutting Metal

If you frequently work with metal or need to cut thicker or denser materials, it is recommended to use specialized metal-cutting tools. Here are some alternatives to using a table saw for cutting metal:

– Metal-cutting bandsaw: A bandsaw designed for cutting metal offers better control, precision, and cutting capacity for various types of metals.

– Plasma cutter: A plasma cutter uses a high-velocity jet of ionized gas to cut through metal quickly and efficiently.

– Waterjet cutter: A waterjet cutter uses a high-pressure jet of water mixed with an abrasive material to cut through metal with precision.

Using a Table Saw for Metal: Things to Consider

While a table saw can be used to cut thin sheets of non-ferrous metals, it is important to consider the safety precautions, limitations, and alternatives before proceeding. Always prioritize safety by wearing appropriate protective gear and taking the necessary safety measures. Assess your specific cutting needs and materials to determine if a table saw is the best tool for the job or if a specialized metal-cutting tool would be more suitable.

Key Takeaways: Can You Use a Table Saw for Metal?

1. Using a table saw for cutting metal is not recommended.

2. Table saws are designed for cutting wood and may not be able to handle the force and heat generated by cutting metal.

3. Metal cutting requires special tools and techniques, such as using a metal-cutting bandsaw or angle grinder.

4. Using a table saw for metal can damage the saw blade and pose safety risks.

5. It is always best to use the right tools for the job to ensure safety and achieve accurate results.

Frequently Asked Questions

Curious about using a table saw for metal? Here are some commonly asked questions and their answers to help you out!

1. Can a table saw be used for cutting metal?

Yes, a table saw can be used for cutting metal, but it requires the right blade and precautions. You’ll need a special blade designed for cutting metal, such as a carbide-tipped blade with closely spaced teeth. These blades are specifically made to handle the hardness and density of metal, ensuring clean and precise cuts.

However, it’s important to note that using a table saw for metal does come with risks. Metal shavings can cause sparks, so make sure your work area is clear of flammable materials. Additionally, the heat generated during cutting can cause the metal to expand, potentially causing the blade to bind or kick back. Always wear suitable safety gear, like gloves and safety glasses, and work slowly and carefully.

2. What are the benefits of using a table saw for metal cutting?

Using a table saw for cutting metal offers several benefits. Firstly, it provides more stability and control compared to using handheld tools. The table and fence of the saw help in guiding the metal, resulting in more accurate cuts. Additionally, the adjustable cutting depth and angle settings of a table saw allow for more precise and customizable cuts.

Moreover, using a table saw can save you time and effort. Instead of cutting by hand, which can be labor-intensive and time-consuming, a table saw allows for faster and more efficient cutting. With the right setup and precautions, a table saw can be a reliable tool for metalworking projects.

3. What types of metal can be cut with a table saw?

A table saw can cut various types of metal, including aluminum, brass, copper, and steel. However, the thickness and hardness of the metal will determine the saw’s ability to cut through it. Thinner and softer metals are generally easier to cut, while thicker and harder metals may require more specialized blades and equipment.

It’s important to remember that each metal has its own unique properties, and certain metals may require different cutting techniques or specific blade types. Always check the manufacturer’s recommendations and consult with experts if you’re unsure about cutting a specific type of metal.

4. Are there any limitations to using a table saw for metal cutting?

Yes, there are some limitations to using a table saw for cutting metal. One limitation is the size of the material. Table saws have a limited cutting capacity, so if you need to cut larger pieces of metal, you may need alternative tools or larger industrial-grade table saws.

Furthermore, a regular table saw may not be suitable for extremely hard metals, such as hardened steel or iron. These materials may require specialty saws with higher power and more robust construction. Always consider the type and thickness of the metal you plan to cut and ensure you have the appropriate tools.

5. What safety precautions should I follow when using a table saw for cutting metal?

When using a table saw for cutting metal, it’s crucial to prioritize safety. Here are some essential precautions to follow:

Firstly, wear appropriate safety gear, including safety glasses, gloves, and hearing protection. Metalworking can create sparks and debris, so protect yourself accordingly.

Secondly, ensure the work area is well-ventilated and clear of flammable materials. Metal shavings can create sparks, which could cause a fire hazard.

Lastly, take your time and work cautiously. Keep the metal firmly against the table and fence, using a push stick or jig if necessary. Don’t rush the cuts, and avoid forcing the metal through the blade. Remember, safety should always be your top priority.

Summary

Can you use a table saw for metal? Nope, it’s not the best tool for the job. Table saws are designed for cutting wood, not metal. Metal requires different tools like a bandsaw or angle grinder. Safety is also a big concern, as using a table saw for metal can cause sparks and damage the blade.

But don’t worry! There are plenty of other tools available that can handle your metal cutting needs. Just make sure to choose the right tool for the job and always prioritize safety. Happy cutting!