Have you ever wondered if you can use a table saw to cut metal? Well, you’re in the right place! Whether you’re a curious DIY enthusiast or a budding carpenter, this topic is sure to pique your interest. In this article, we’ll explore the possibilities and safety considerations of using a table saw to tackle metal-cutting tasks. So, let’s dive in and discover if it’s a match made in workshop heaven!

Now, you may be thinking, “Why would anyone want to cut metal with a table saw?” Fair question! Table saws are primarily designed for woodcutting, but with the right setup and precautions, they can handle metal too. We’ll uncover the why behind this intriguing possibility, as well as the potential challenges you might encounter along the way. So, buckle up and get ready for an exciting journey into the world of cutting metal with a table saw!

Before we begin, it’s crucial to emphasize safety. Metal cutting can pose unique risks, but fear not! We’ll walk you through essential safety measures to ensure you’re well-equipped to handle this task. From protective gear to proper techniques, we’ve got your back. So, let’s gear up and dive into the fascinating realm of using a table saw to cut metal!

Wondering if you can use a table saw to cut metal? While table saws are primarily designed for cutting wood, there are certain types of saw blades that can handle cutting through metal. However, it’s important to note that using a table saw to cut metal requires specific safety precautions and the right blade. Make sure to wear appropriate protective gear and use a carbide-tipped or diamond blade specifically designed for metal cutting.

Can You Use a Table Saw to Cut Metal?

In the world of woodworking, the table saw reigns supreme as the go-to tool for making precision cuts in wood. But what about cutting metal? Can a table saw handle this task as well? Let’s explore this question and delve into the possibilities, limitations, and safety considerations of using a table saw to cut metal.

Can a Table Saw Cut Metal: The Possibilities and Limitations

When it comes to cutting metal, a table saw can be a useful tool, but it does have its limitations. Let’s take a closer look at when and how you can use a table saw for cutting metal.

1. Metal Types

Not all types of metal are suitable for cutting on a table saw. Soft materials like aluminum and copper tend to be more manageable, while harder metals like steel require specialized blades and techniques. It’s important to consider the type of metal you’re working with before attempting to cut it on a table saw.

One thing to keep in mind is that metals like aluminum and copper can leave marks on the table saw’s surface, so taking proper precautions like using sacrificial surfaces or non-marring materials is crucial to prevent damage to your saw.

2. Blade Selection

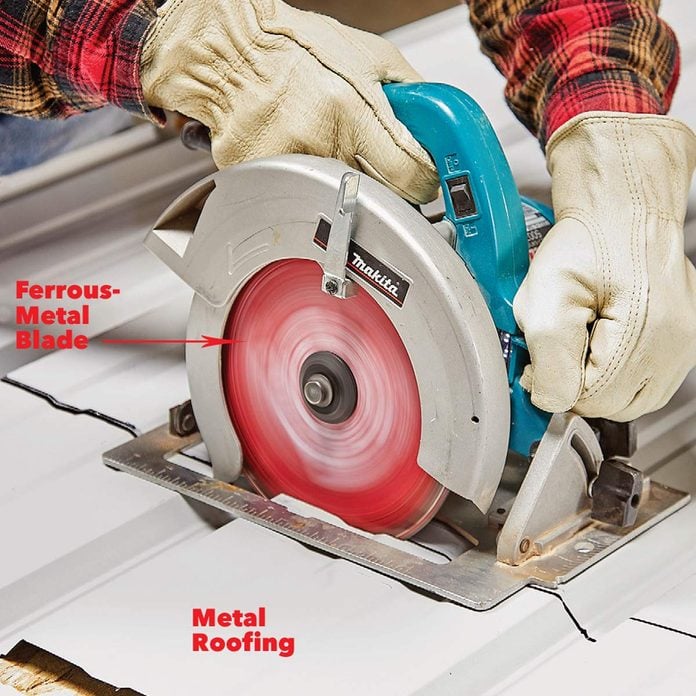

The blade you use on a table saw plays a significant role in cutting metal. Regular wood-cutting blades are not designed to cut through metal, so using them can result in poor cuts, damaged blades, or even dangerous kickbacks. Instead, opt for specialized metal-cutting blades specifically designed for table saw use.

These blades typically have a higher number of teeth and are made from stronger materials like carbide or diamond, allowing them to make smoother and more precise cuts in metal. It’s essential to choose the right blade for the type of metal you’re working with to ensure optimal results.

3. Blade Height and Angle

When cutting metal on a table saw, it’s crucial to set the blade height and angle correctly. Unlike wood, metal is denser and requires a slower feed rate to prevent overheating and blade wear. Setting the blade height slightly higher than the thickness of the metal and maintaining a shallow blade angle can help improve cutting performance and minimize the risk of blade damage.

However, it’s important to note that cutting metal generates sparks, and those sparks can potentially ignite sawdust or other flammable materials. Taking adequate safety measures like having a clean and clutter-free workspace, using protective goggles, and wearing fire-resistant clothing can mitigate this risk.

4. Safety Considerations

Using a table saw to cut metal requires extra caution and safety measures. Metal can be harder to control and more unpredictable than wood. The risk of kickbacks and flying debris is higher when cutting metal, so it’s important to use push sticks, feather boards, and other safety accessories to maintain control over the workpiece and minimize the risk of injury.

Additionally, metal generates heat when being cut, leading to potential thermal expansion. This can cause the workpiece to bind against the fence or kickback unexpectedly. Keeping a safe working distance from the blade and using appropriate feeding techniques can help reduce these risks.

5. Alternatives to Table Saws

While a table saw can serve as a viable option for cutting metal, there are alternatives that may be better suited for specific metal-cutting tasks.

Band saws, for instance, are often preferred for cutting thicker metal stock or irregular shapes. Their continuous cutting motion and ability to use a wider range of blade types make them highly versatile. However, band saws may not deliver the same precision as a table saw in some cases.

Another alternative is using a metal-cutting circular saw or a dedicated metal-cutting machine. These tools are specifically designed for cutting metal and offer features and capabilities that surpass those of a traditional table saw.

The Benefits of Using a Table Saw to Cut Metal

Despite the limitations and safety considerations, there are distinct benefits to using a table saw for cutting metal.

1. Precision Cutting

A table saw is known for its precision cutting capabilities in woodworking, and it can deliver similar results when cutting metal. With the right blade and setup, a table saw can make clean, straight cuts, ensuring accuracy and tight tolerances.

2. Versatility

By equipping a table saw with a specialized metal-cutting blade, you can expand its versatility and tackle various materials without the need for multiple tools. This can be particularly beneficial for hobbyists or small-scale metalworking projects.

3. Efficiency

Table saws are efficient machines that allow for quick set-up and adjustment. Once properly configured for metal cutting, they can deliver consistent and repeatable results, saving time and effort.

4. Cost-Effectiveness

If you already own a table saw and need to cut metal occasionally, utilizing it for metal cutting tasks can be a cost-effective solution. Instead of investing in a separate metal-cutting machine, you can maximize the potential of your existing tool without breaking the bank.

Tips for Using a Table Saw to Cut Metal

To ensure safe and successful metal cutting on a table saw, here are some essential tips to keep in mind:

1. Use the Right Blade

Invest in high-quality metal-cutting blades specifically designed for table saw use. Choose the appropriate blade type and tooth count based on the metal you’re working with.

2. Take Safety Precautions

Wear protective goggles, gloves, and fire-resistant clothing. Keep your workspace clean and free of flammable materials. Use safety accessories like push sticks, feather boards, and hold-down clamps to maintain control over the workpiece.

3. Practice Proper Feeding Techniques

Feed the metal into the blade slowly and steadily to prevent overheating, blade wear, and potential kickbacks. Avoid rushing or forcing the metal through the blade.

4. Know the Limits

Understand the limitations of your table saw when it comes to cutting metal. If the project requires intricate or specialized cuts, consider using alternative tools like band saws or dedicated metal-cutting machines.

In conclusion, while a table saw can handle cutting metal, it’s important to approach the task with caution, adhere to safety measures, and use the right blades and techniques. Always prioritize your safety and choose the right tool for the job based on your specific metal-cutting needs.

Key Takeaways: Can You Use a Table Saw to Cut Metal?

- Using a table saw to cut metal is not recommended.

- Table saws are designed for cutting wood, not metal.

- Using a table saw to cut metal can damage the saw blade and the metal being cut.

- Table saws lack the necessary power and specialized features for cutting metal.

- It’s important to use the right tool for the job – for cutting metal, use a dedicated metal-cutting saw or blade.

Frequently Asked Questions

When it comes to using a table saw, many people wonder if it can be used to cut metal. Here are some common questions and answers related to this topic.

1. Can you cut metal with a regular table saw?

No, a regular table saw is not specifically designed for cutting metal. It is mainly used for cutting wood and other softer materials. Trying to cut metal with a regular table saw can damage the blade and pose a safety risk.

If you need to cut metal, it is best to use a saw specifically designed for metal, such as a metal-cutting bandsaw, a cold saw, or an abrasive chop saw.

2. What are the risks of using a table saw to cut metal?

Using a regular table saw to cut metal can lead to several risks. Firstly, the blade can get damaged or dulled quickly when cutting through metal, resulting in a reduced cutting performance and potential safety hazards. Additionally, metal debris can fly off the blade, posing a risk of injury to the user or others nearby.

Furthermore, most table saws are not equipped with the necessary safety features, such as special blades or guards, to safely cut through metal. It is essential to prioritize safety and use the appropriate tools for the job.

3. Are there any table saw alternatives for cutting metal?

Yes, there are several alternatives to using a table saw for cutting metal. One popular option is a metal-cutting bandsaw, which is specifically designed for cutting metal. These saws have a slower speed and a blade with more teeth, allowing for cleaner and more accurate cuts on metal materials.

Another alternative is a cold saw, which uses a circular blade, coolant, and a slow cutting speed to minimize heat and produce precise cuts in metal. Additionally, an abrasive chop saw, which utilizes a high-speed abrasive wheel, can also be used for cutting metal.

4. Can you modify a table saw for cutting metal?

While it is technically possible to modify a table saw for cutting metal, it is not recommended. Modifying the saw may void its warranty, compromise its safety features, and lead to inaccurate or unsafe cuts. It is best to invest in a tool specifically designed for cutting metal to ensure efficient and safe metal cutting.

If you frequently work with metal, it is advisable to invest in a dedicated metal-cutting saw rather than attempting to modify a table saw. This will provide better results and reduce the risk of accidents.

5. What safety precautions should be followed when cutting metal?

When cutting metal, it is crucial to follow proper safety precautions. Firstly, always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection. This will help protect against the potential hazards associated with metal cutting, such as flying sparks and debris.

Additionally, ensure that the work area is clean and free from clutter, as metal scraps and tools can increase the risk of accidents. Always use the correct tool and blade for cutting metal, and follow the manufacturer’s instructions for safe operation. Lastly, take your time, maintain focus, and work at a controlled pace to ensure accuracy and reduce the risk of injuries.

Summary

Using a table saw to cut metal can be dangerous and is not recommended for several reasons. Firstly, the high speed of the saw blade can cause the metal to heat up and potentially warp or damage it. Secondly, table saws are typically designed for cutting wood, not metal, so they may not have the necessary features or safety measures in place. It is best to use a saw specifically designed for cutting metal to ensure safety and accurate results.