Looking to expand your knowledge of machining tools? Curious about whether you can use an end mill in a lathe? Well, you’ve come to the right place! We’re here to answer all your burning questions about these powerful tools and their compatibility. So sit tight and get ready for an exciting journey into the world of machining!

Now, you might be wondering, “Can you use an end mill in a lathe?” It’s a great question, and the answer may surprise you. While traditional lathes are primarily designed for turning operations, there are certain situations where you can utilize an end mill in a lathe.

So, buckle up and join us as we delve into the world of machining to uncover the ins and outs of using an end mill in a lathe. Let’s explore the possibilities and discover how you can maximize the potential of these fantastic tools together!

- Secure the end mill in a collet or a proper milling chuck.

- Choose the appropriate speed and feed rate for your lathe.

- Position the end mill against the workpiece and ensure it is aligned properly.

- Engage the lathe spindle and slowly feed the end mill into the workpiece.

- Rotate the lathe chuck by hand to ensure smooth and accurate cutting.

Using an end mill in a lathe requires careful setup and execution, but it can expand the capabilities of your lathe for milling operations.

Can You Use an End Mill in a Lathe?

Introduction: When it comes to machining, there are different tools that serve specific purposes. Two common tools used in machining are end mills and lathes. End mills are typically used in milling machines, while lathes are designed for turning operations. However, there may be instances where you wonder if it’s possible to use an end mill in a lathe. In this article, we will explore the compatibility of using an end mill in a lathe, its advantages and disadvantages, as well as some practical tips.

The Compatibility of Using an End Mill in a Lathe

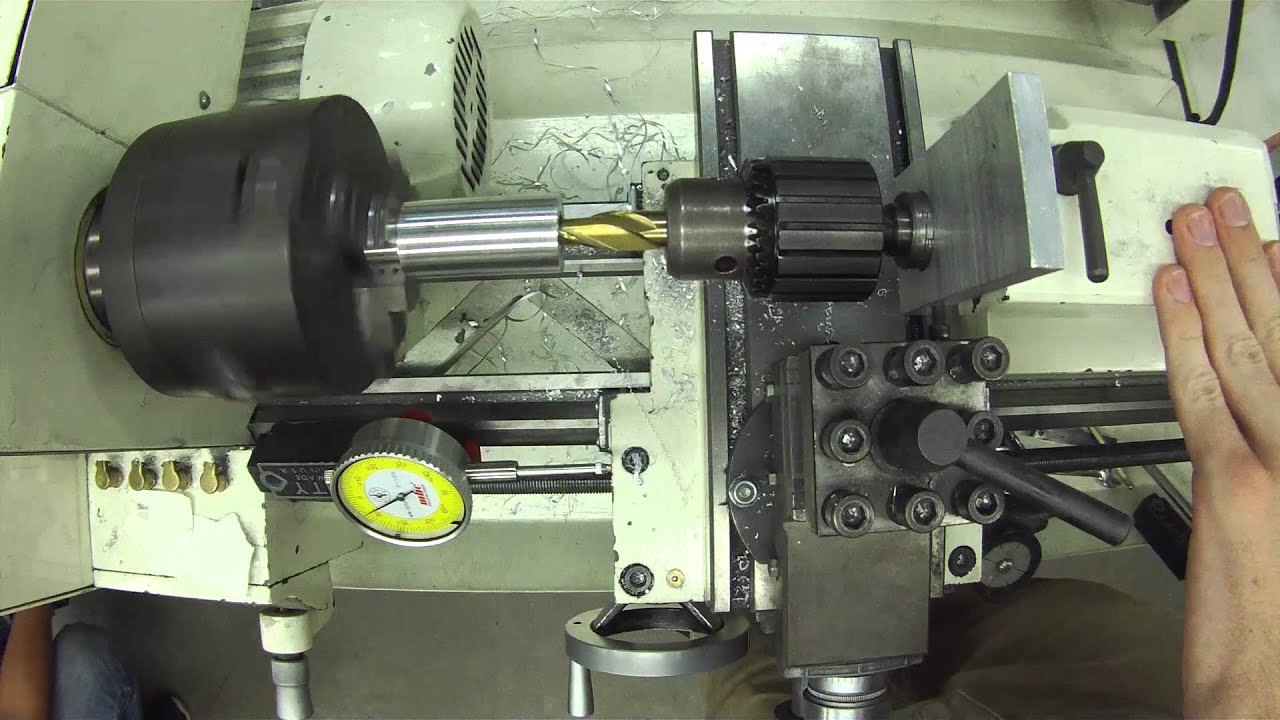

Using an end mill in a lathe is not the standard practice, but it is possible in certain situations. An end mill is designed to be used in a milling machine where the workpiece is stationary and the cutter moves in multiple directions to remove material. On the other hand, a lathe is used for rotating the workpiece and cutting tools are typically fixed in position. However, if you have a lathe with a milling attachment or a lathe with a rotating spindle, it is possible to mount an end mill and perform milling operations.

One of the main considerations when using an end mill in a lathe is the stability of the setup. Since lathes are not specifically designed for milling, you may experience limitations in terms of rigidity and tool positioning. It’s important to ensure that the setup is secure and that the cutting forces can be properly handled by the lathe. Additionally, the size and type of end mill you use should be suitable for the lathe’s capabilities to avoid damaging either the machine or the workpiece.

While using an end mill in a lathe may have its limitations, it can be a viable option for certain applications. It allows you to perform milling operations on cylindrical or round workpieces without the need for a separate milling machine. However, it’s essential to carefully evaluate the compatibility of your lathe and the specific end mill you intend to use to ensure safe and efficient machining.

Advantages and Disadvantages of Using an End Mill in a Lathe

Advantages:

- No need for a separate milling machine: One of the main advantages of using an end mill in a lathe is the ability to perform milling operations without investing in an additional machine. This can be cost-effective, especially for small-scale machining operations.

- Versatility: Using an end mill in a lathe allows you to perform a range of milling operations, such as slotting, drilling, and contouring, on cylindrical or round workpieces.

- Space-saving: If you have limited workspace, combining the functionalities of a lathe and a mill can be beneficial as it requires less floor space compared to having both machines separately.

Disadvantages:

- Limited rigidity: Lathes are not designed for the same level of rigidity and stability as milling machines. This may result in reduced accuracy and surface finish when using an end mill in a lathe.

- Tool positioning: The fixed tool positioning in a lathe may limit the range of milling operations you can perform. It may be more challenging to achieve complex shapes and features compared to using a dedicated milling machine.

- Lower spindle speeds: Lathes typically have lower spindle speeds compared to milling machines. This can affect the cutting efficiency and surface finish, especially when using smaller diameter end mills.

Tips for Using an End Mill in a Lathe

If you decide to use an end mill in a lathe, here are some tips to ensure a successful machining process:

- Choose the right end mill: Select a suitable end mill based on the material you are machining, the desired cutting parameters, and the capabilities of your lathe. Consider factors such as flute count, coating, and cutting edge geometry.

- Secure the workpiece: Ensure that the workpiece is securely held in place to prevent any movement or vibration during the milling process. Use appropriate clamping or fixturing techniques for the specific workpiece geometry.

- Set proper speeds and feeds: Adjust the spindle speed and feed rate according to the material and the specific end mill being used. Consult the manufacturer’s recommendations and make adjustments as necessary to achieve optimal cutting performance.

- Take light cuts: Due to the lower rigidity of a lathe setup, it is advisable to take light cuts instead of heavy machining passes. This helps to reduce the cutting forces and minimize the chances of tool breakage or damage to the lathe.

- Monitor the process: Pay close attention to the machining process and monitor for any signs of tool wear, vibrations, or other issues. Make any necessary adjustments during the machining process to maintain quality and accuracy.

- Practice safety precautions: Always follow safety guidelines when operating any machining equipment. Wear appropriate personal protective equipment, use guards when applicable, and ensure a clean and organized work area.

- Seek expert advice if unsure: If you are unsure about using an end mill in your lathe or have specific questions regarding your setup, it is advisable to consult with experts or experienced machinists who can provide guidance based on their knowledge and expertise.

Additional H2 Headings:

Benefits of Using a Dedicated Milling Machine

Introduction: While using an end mill in a lathe can have its advantages, there are also benefits to using a dedicated milling machine. In this section, we will explore the advantages of using a milling machine for milling operations, as well as its capabilities compared to a lathe.

Key Differences Between End Mills and Lathe Tools

Introduction: End mills and lathe tools are distinct in their design and intended usage. Understanding the key differences between these tools can help you make informed decisions when choosing the right tool for your machining needs. In this section, we will compare end mills and lathe tools in terms of their design, cutting capabilities, and applications.

Conclusion

In this article, we discussed the compatibility of using an end mill in a lathe, its advantages and disadvantages, as well as some practical tips for successful machining. While using an end mill in a lathe is not the standard practice, it can be a viable option for certain applications. However, it’s important to carefully evaluate the compatibility and limitations of your lathe and the specific end mill you intend to use to ensure safe and efficient machining. Additionally, considering the benefits of using a dedicated milling machine and understanding the key differences between end mills and lathe tools can further inform your decision-making process. Ultimately, the choice between using an end mill in a lathe or opting for a dedicated milling machine will depend on the specific requirements of your machining projects and the resources available to you.

Key Takeaways: Can You Use an End Mill in a Lathe?

- 1. An end mill, which is typically used in milling machines, is not designed to be used in a lathe. Lathes are designed for cylindrical turning operations.

- 2. Attempting to use an end mill in a lathe can result in poor results and potential damage to the machine.

- 3. End mills are optimized for cutting on the sides and bottom, while lathes are optimized for cutting on the outside of cylindrical workpieces.

- 4. It is important to use the correct tooling for each specific machine to achieve the best results.

- 5. If you need to perform milling operations on a lathe, it is recommended to use a milling attachment or a milling machine for better results.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we provide answers to common queries about using an end mill in a lathe. Whether you’re a beginner or experienced machinist, these answers will help you understand the compatibility and best practices for using an end mill in a lathe.

1. What is the main difference between a lathe and a mill?

While both machines are used for machining, a lathe and a mill serve different purposes. A lathe is primarily used for shaping cylindrical or round objects, such as rods or spindles. It rotates the workpiece while a cutting tool removes material to achieve the desired shape. On the other hand, a mill is designed to cut and shape flat surfaces and perform various milling operations by moving the workpiece and the cutting tool.

So, the key difference is that a lathe rotates the workpiece for cutting, while a mill moves the cutting tool.

2. Can you use an end mill in a lathe?

Technically, it is possible to use an end mill in a lathe to perform certain tasks. However, it is not a common practice and should be approached with caution. End mills are primarily designed for use in milling machines where the workpiece remains stationary, and the cutting tool moves. Using an end mill in a lathe, where the workpiece rotates, can be challenging and may cause issues such as chatter, poor surface finish, and tool breakage.

If you need to perform milling operations on a lathe, it is recommended to use dedicated lathe milling attachments or to consider using a milling machine instead, which is designed specifically for such tasks.

3. Is it possible to achieve accurate results by using an end mill in a lathe?

While it may be possible to achieve acceptable results with careful setup and proper techniques, using an end mill in a lathe is generally not the most accurate method. The design and setup of a lathe are optimized for turning operations, and the machine’s precision and rigidity may not be suitable for precise milling work.

If accuracy is crucial for your project, it is recommended to use a milling machine, which is designed to provide more precise control and stability for milling operations.

4. Are there any safety concerns when using an end mill in a lathe?

Yes, there are safety concerns associated with using an end mill in a lathe. The rotational forces and vibrations generated when using an end mill in a lathe can be greater compared to using it in a milling machine. This can increase the risk of tool breakage, workpiece ejection, and other safety hazards.

Always prioritize safety when machining and follow the manufacturer’s guidelines for both the lathe and the end mill. Consult with experienced machinists or professionals if you need assistance in determining the safest and most efficient machining methods.

5. What are the alternatives to using an end mill in a lathe?

If you need to perform milling operations and do not have access to a milling machine, there are alternative methods you can consider. One option is to use lathe milling attachments, which are designed specifically for milling on a lathe. These attachments provide more stability and control for milling operations on a lathe.

Another alternative is to outsource your milling tasks to a machine shop or use a CNC (Computer Numerical Control) milling service. These options can ensure accurate and precise milling results without the need for investing in milling equipment.

Summary

So, can you use an end mill in a lathe? The answer is no. End mills are designed for milling operations, not lathe work. Lathe tools and end mills have different shapes and functions. It’s important to use the right tool for the right job to ensure safety and achieve the best results. If you need to perform milling operations, it’s best to use a milling machine instead of a lathe. Remember, always use the appropriate tool for the task at hand!