Wondering if you can use any circular saw with a track? Well, you’re in the right place! Let’s dive into the world of circular saws and tracks to find out how they work together.

Using a circular saw with a track can make your woodworking projects more precise and efficient. But not all circular saws are compatible with tracks. So, it’s essential to understand which ones are and how to use them effectively.

In this article, we’ll explore the compatibility of circular saws with tracks and provide valuable insights to help you make the most of your woodworking adventures. So, let’s get started and unlock the secrets of using circular saws with tracks!

If you’re wondering whether you can use any circular saw with a track, the answer is yes! Using a circular saw with a track allows for more precise and straight cuts. Simply attach a compatible track to your circular saw and start cutting. Make sure to choose a track that is the right size and compatible with your saw model. With the right setup, you’ll be able to achieve clean and accurate cuts every time.

Can You Use Any Circular Saw with a Track?

In the world of woodworking and DIY projects, precision and accuracy are essential. One tool that can help achieve this is a track system, which allows you to guide your circular saw along a fixed path. But can you use any circular saw with a track? In this article, we will delve into this question and explore the compatibility between circular saws and track systems. Whether you are a professional woodworker or a hobbyist, understanding the capabilities of your tools is crucial for achieving the best results.

The Benefits of Using a Circular Saw with a Track

A circular saw paired with a track system offers several advantages that can elevate your cutting game to the next level. Let’s take a closer look at the benefits:

1. Enhanced Precision and Accuracy:

One of the key advantages of using a circular saw with a track is the ability to achieve precise and accurate cuts. The track acts as a guide, ensuring that the saw moves in a straight line, eliminating the risk of veering off course. This feature is especially useful when making long, straight cuts, such as when cutting plywood sheets or trimming doors.

Additionally, the track system often includes built-in measurements, allowing you to make precise cuts without the need for manual marking and measuring. This saves time and reduces the margin for error, resulting in cleaner and more professional-looking cuts.

Furthermore, using a track system minimizes the risk of blade deflection. When cutting freehand, there is a higher chance of the circular saw’s blade bending, leading to less accurate cuts. The track helps stabilize the blade, ensuring that it remains aligned during the entire cutting process.

2. Versatility and Flexibility:

Another advantage of using a circular saw with a track is the versatility it offers. Most track systems are compatible with various sizes and models of circular saws, allowing you to use different saws based on the requirements of your project.

This flexibility enables you to tackle a wide range of cutting tasks, from ripping boards to cross-cutting sheet goods. Whether you’re working on a small craft project or building furniture, a circular saw with a track system can adapt to your needs, providing consistent results every time.

3. Safety and Control:

Using a circular saw with a track system can enhance safety and control while making cuts. The track acts as a barrier, reducing the risk of accidental slips or kickbacks. This is especially beneficial for beginner woodworkers or those who are less experienced with power tools.

Additionally, the track system often includes anti-splinter strips, which help prevent tear-out along the cut line. This feature is especially important when working with fragile or expensive materials, as it ensures clean and damage-free cuts.

Furthermore, the fixed path provided by the track system promotes better control over the saw, allowing you to focus on maneuvering the tool rather than worrying about staying on track. This can result in increased confidence and improved cutting accuracy.

Things to Consider When Choosing a Circular Saw for Track Compatibility

While track systems are designed to be compatible with various circular saws, there are a few factors to consider when selecting a circular saw for use with a track system. These include:

1. Base Plate Design:

The base plate of the circular saw is a critical element to consider as it needs to be compatible with the track system. Look for saws with base plates that feature guide channels or slots that align with the track’s guide ribs. This ensures a secure fit between the saw and the track, allowing for smooth and accurate cuts.

Some manufacturers offer specific base plates designed for their track systems, providing optimum compatibility and performance. If you are investing in a track system, it may be worth considering a circular saw from the same manufacturer.

2. Track Compatibility:

Not all track systems are created equal, and some may only be compatible with specific circular saw brands or models. Before purchasing a circular saw or track system, check the manufacturer’s recommendations to ensure compatibility.

It’s also important to consider the length of the track and whether it suits the types of cuts you commonly make. Longer tracks are ideal for cutting large sheets of material, while shorter tracks may be suitable for smaller-scale projects.

3. Power and Performance:

When using a circular saw with a track system, it’s crucial to ensure that the saw has enough power and performance to handle the cutting tasks you have in mind. Consider the motor’s horsepower, blade speed, and cutting depth capacity to ensure it meets your specific needs.

A more powerful saw may be required for cutting through thick or dense materials, while a lighter, portable saw may be sufficient for lighter-duty projects. Take into account the type of materials you typically work with and choose a circular saw that can handle those demands.

Basic Steps for Using a Circular Saw with a Track

Now that we have discussed the benefits and considerations of using a circular saw with a track, let’s walk through the basic steps for using this setup:

Step 1: Set Up the Track System:

Start by laying out the track on your workpiece, ensuring it is straight and properly aligned. Most track systems have an anti-slip coating on the underside, which helps keep the track securely in place.

If necessary, use clamps or other securing mechanisms to hold the track in position. It’s important to ensure that the track is stable and won’t shift during the cutting process.

Step 2: Prepare the Circular Saw:

Attach the compatible base plate to your circular saw, making sure it is securely fastened. Check that the blade is sharp and in good condition, as a dull blade can lead to rough cuts or splintering.

Adjust the cutting depth of the circular saw according to the thickness of your material. Most circular saws have a depth adjustment mechanism that allows you to set the desired cutting depth.

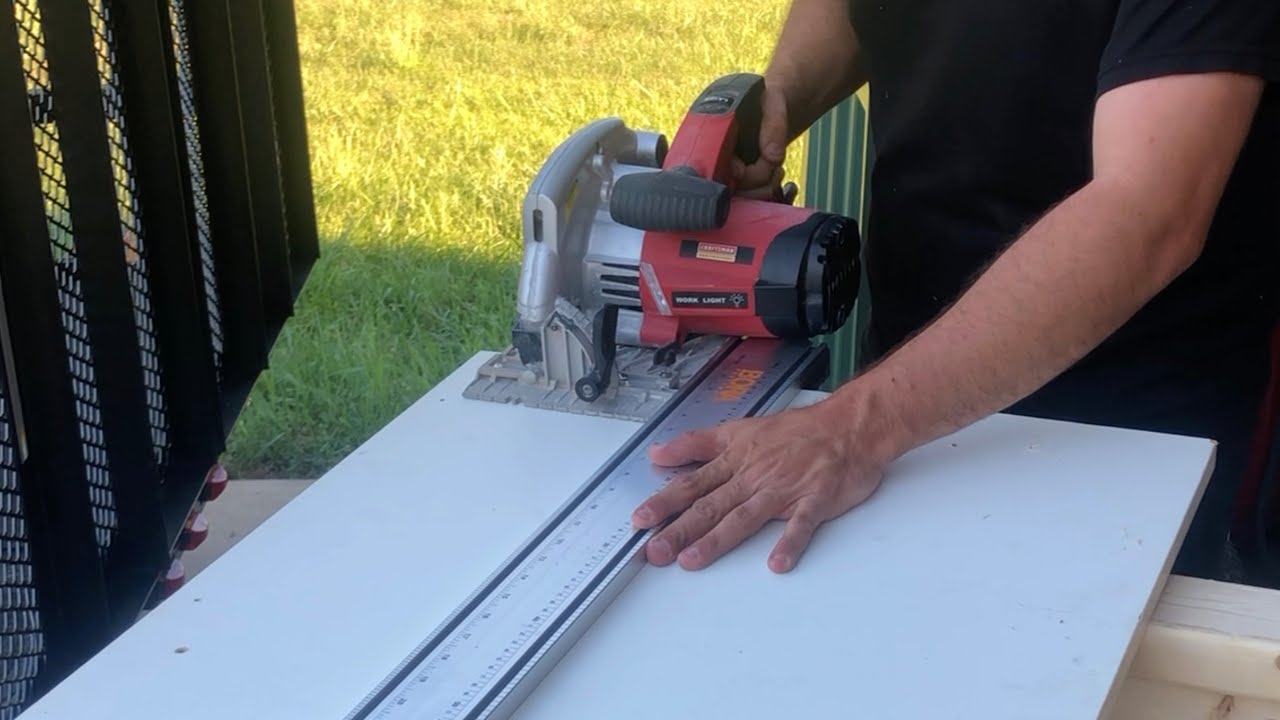

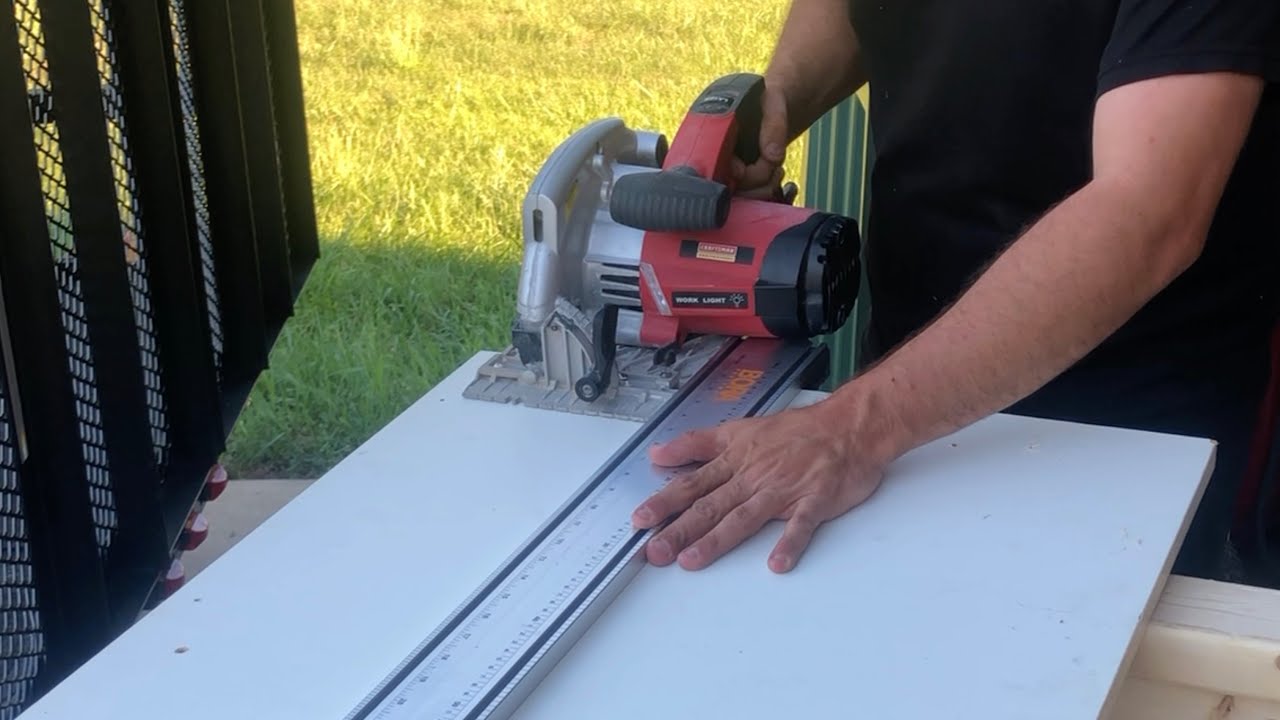

Step 3: Align the Saw with the Track:

Place the circular saw onto the track, aligning the guide channels or slots on the saw’s base plate with the guide ribs on the track. Ensure a snug fit between the saw and the track.

Some circular saws have a locking mechanism that helps secure the saw in place on the track. Engage the locking mechanism, if available, to prevent lateral movement of the saw during cutting.

Step 4: Make the Cut:

Start the circular saw and slowly guide it along the track, maintaining a firm grip and applying steady pressure. Let the saw do the work, allowing the blade to cut through the material without forcing it.

Use both hands to control the saw, keeping your fingers away from the blade and ensuring a stable and balanced cutting motion. Follow the marked path on the track, and continue cutting until you reach the end of the material.

Step 5: Repeat and Adjust as Needed:

If you need to make additional cuts, repeat the process starting from Step 3. Take your time and double-check the alignment before each cut to ensure accuracy.

If adjustments are necessary, such as changing the cutting depth or repositioning the track, make the necessary changes before proceeding with the next cut.

Conclusion

Using a circular saw with a track system can greatly enhance the precision, accuracy, and versatility of your woodworking projects. Although compatibility between circular saws and track systems is essential, many circular saws are designed to work seamlessly with various track systems.

By considering factors such as base plate design, track compatibility, and the power and performance of the circular saw, you can ensure a smooth and successful cutting experience. Remember to follow the manufacturer’s instructions for your specific circular saw and track system to achieve the best results.

Next time you embark on a woodworking project that requires precise and straight cuts, consider using a circular saw with a track system for professional-level accuracy and results.

Key Takeaways: Can You Use Any Circular Saw with a Track?

- Not all circular saws are designed to be used with a track.

- Some circular saw models have specific features to be compatible with tracks.

- Using a circular saw with a track provides increased accuracy and precision.

- Check the specifications and instructions of your circular saw to determine if it can be used with a track.

- If your circular saw is not compatible with a track, consider purchasing a dedicated track saw for better results.

Frequently Asked Questions

When it comes to using a circular saw with a track, there are some important considerations to keep in mind. Here are some common questions that people have about this topic.

1. How do I know if my circular saw is compatible with a track?

The compatibility of your circular saw with a track depends on a few factors. First, check if your circular saw has a groove or channel for a track. This groove allows the saw to ride smoothly along the track. Additionally, ensure that the width of the track is compatible with the base plate of your circular saw. Some tracks are designed to fit specific models or brands of circular saws, so it’s important to check the compatibility before using a track.

If your circular saw doesn’t have a groove for a track, you may be able to purchase an accessory that attaches to the saw and allows it to work with a track. These accessories typically include an attachment that clamps onto the saw and provides a channel for the track. Just make sure to follow the manufacturer’s instructions and guidelines for using the accessory safely and effectively.

2. Can I use any track with my circular saw?

While there are universal tracks available on the market, it’s important to note that not all tracks will work with every circular saw. The width of the track should match the base plate of your circular saw to ensure a proper fit. Additionally, some tracks may be designed specifically for certain types or brands of circular saws, so it’s important to check the compatibility before purchasing a track.

When choosing a track, consider the length and durability as well. Longer tracks are useful for cutting longer boards, while shorter tracks can be more portable and easier to maneuver. Look for tracks made from high-quality materials that offer stability and precision during cutting. Reading reviews and researching different track options can help you find the best one for your circular saw.

3. Are there any advantages to using a circular saw with a track?

Using a circular saw with a track offers several advantages. First and foremost, it improves the accuracy of your cuts. The track acts as a guide, ensuring that your cuts are straight and precise. This can be particularly useful for tasks like cutting large sheets of plywood or making long, straight cuts.

Additionally, using a track can improve safety by reducing the risk of the saw slipping or veering off course. The track provides a stable base for the saw, minimizing the chances of accidents or mistakes. Finally, using a track can also save time and effort by eliminating the need for measuring and marking multiple cuts. With a track, you can simply align the saw with the desired cutting line on the track and make your cut.

4. Can I use a circular saw with a track for bevel cuts?

Yes, many tracks are designed to accommodate bevel cuts. Look for tracks that have adjustable angle settings to allow for bevel cuts at different angles. Additionally, ensure that your circular saw has the capability to make bevel cuts as well. Some saws have a bevel adjustment feature that allows you to tilt the blade to the desired angle for bevel cuts.

When using a circular saw with a track for bevel cuts, it’s important to secure the track correctly and adjust the angle settings accurately. Follow the manufacturer’s instructions for setting up and using the track properly to ensure safe and precise bevel cuts.

5. Can I use a circular saw with a track for plunge cuts?

While a circular saw with a track is primarily designed for straight cuts, some tracks may have features that allow for plunge cuts as well. Plunge cuts are vertical cuts made by starting the cut in the middle of the material rather than at the edge.

If you require the ability to make plunge cuts with your circular saw, look for tracks that have a plunge-cutting feature or accessory. This could be in the form of a detachable stop that allows the saw to plunge into the material at a specific depth. However, it’s important to note that not all tracks offer this feature, so be sure to check the specifications and capabilities of the track before attempting plunge cuts.

Summary

Using any circular saw with a track can make your cutting tasks more accurate and precise. By attaching the track to the workpiece, you can ensure straight and clean cuts every time. However, it’s important to choose a circular saw that is compatible with the track system you plan to use.

Before buying a circular saw, check if it is designed to work with a track. Look for saws that have a built-in track system or ones that are compatible with aftermarket track attachments. Also, consider the size and weight of the saw to ensure it can smoothly glide along the track without any issues. Always follow the manufacturer’s instructions and practice proper safety precautions when using any power tool.