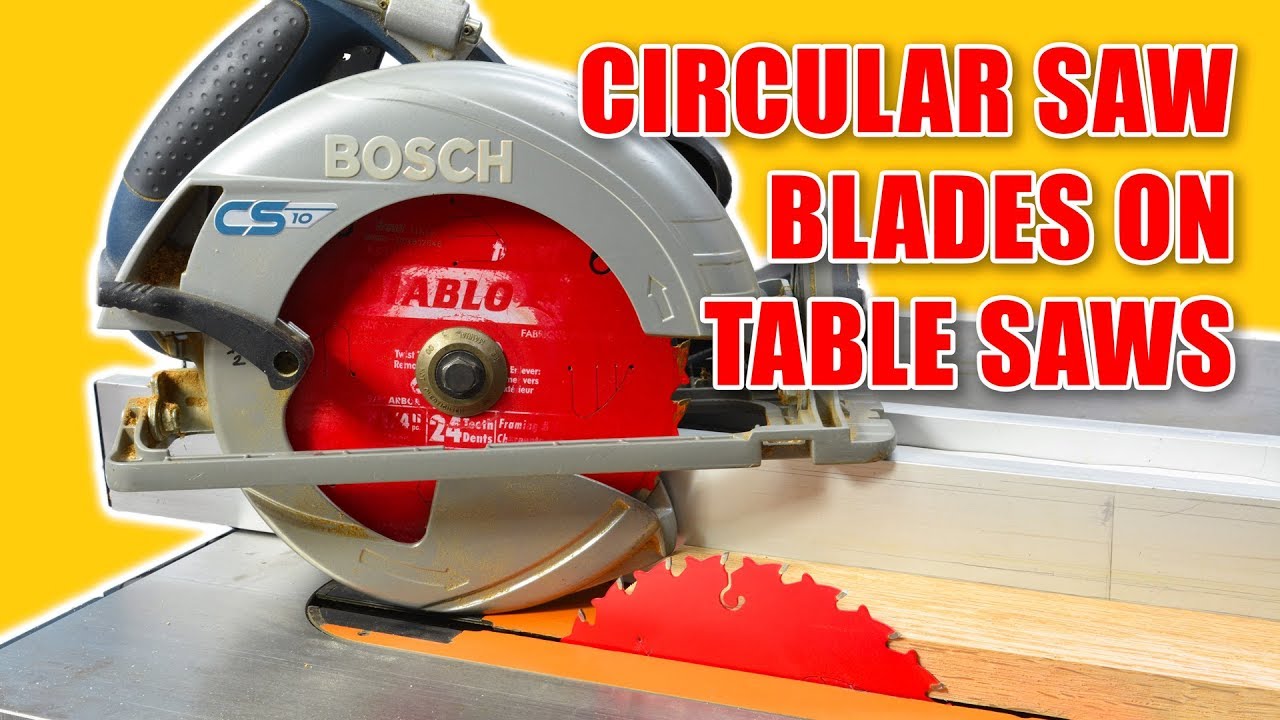

Are you wondering if you can use a circular saw blade on a table saw? Well, let me tell you, it’s a question that many woodworking enthusiasts have asked. So, let’s dive in and explore this topic together!

Using a circular saw blade on a table saw might seem like a quick fix or a way to save some money. But before you grab that circular saw blade and fit it onto your table saw, there are some important factors you need to consider.

In this article, we’ll discuss the compatibility of circular saw blades with table saws, the potential risks involved, and whether it’s a smart choice for your woodworking projects. So, let’s get started and uncover the answer to this exciting question!

Using a circular saw blade on a table saw is not recommended. Circular saw blades are designed for handheld use and have a different tooth geometry than table saw blades. Table saw blades are specifically designed for the unique requirements of the table saw, ensuring safety and optimal performance. It’s important to always use the right blade for the right tool to ensure accurate cuts and prevent accidents.

Can You Use a Circular Saw Blade on a Table Saw?

Introduction:

When it comes to woodworking tools, the circular saw and table saw are two essential pieces of equipment. Both tools have their specific functions and blades, but have you ever wondered if you can interchange the blades? In this article, we will explore whether or not it is possible to use a circular saw blade on a table saw, the potential risks and limitations, and alternative options for achieving the desired cuts.

Understanding the Differences in Blade Design

Circular saw blades and table saw blades may look similar, but they are designed for different purposes. A circular saw blade is typically smaller and has a kerf, or blade thickness, that is thinner than a table saw blade. Additionally, circular saw blades have a higher tooth count compared to table saw blades, allowing for smoother cuts in various materials.

Table saw blades, on the other hand, are generally larger and come in different types depending on the specific application. They have a thicker kerf to provide stability and reduce the risk of damage to the blade. Table saw blades also feature different tooth geometries and angles to accommodate different cutting needs, such as ripping or crosscutting.

Given these differences in design, it is essential to use the appropriate saw blade for the corresponding tool to ensure optimal performance and safety during operation.

The Risks and Limitations of using a Circular Saw Blade on a Table Saw

Attempting to use a circular saw blade on a table saw can be extremely dangerous and should be avoided. The thinner kerf of a circular saw blade may cause it to get stuck in the cut, leading to kickback and potential injury. The lower tooth count on a circular saw blade also makes it less suitable for cutting efficiently on a table saw, resulting in rough cuts and potential damage to the workpiece and blade.

Furthermore, using a circular saw blade on a table saw can put excessive strain on the motor and the arbor of the table saw, leading to premature wear and potential damage. The table saw is not designed to handle the lateral forces and the cutting action of a circular saw blade, which can ultimately compromise the safety and functionality of the machine.

It is crucial to prioritize safety and use the appropriate blade for the intended tool to avoid accidents, maintain the longevity of your equipment, and achieve precise and clean cuts.

Alternatives to Consider

If you are looking for alternatives to achieve similar cutting results as a circular saw blade on a table saw, there are a few options available.

One option is to invest in a quality table saw blade that is designed for the specific type of cut you need. Table saw blades come in various types, such as rip blades for cutting along the grain or crosscut blades for cutting across the grain. By selecting the right blade for the job, you can achieve clean and accurate cuts with the added safety and stability that a table saw provides.

Another alternative is to use a specialized dado blade set on your table saw. A dado blade set allows you to create wide, flat-bottomed grooves or dadoes that can be useful for joinery or enhancing the strength of your woodworking projects. However, it is important to follow the manufacturer’s instructions and use appropriate safety precautions when using dado blades.

Ultimately, it is always recommended to use the correct tool and blade combination for the intended task to ensure safety, precision, and optimal results.

Choosing the Right Blade for Your Table Saw

Understanding the Differences Between Circular Saw Blades and Table Saw Blades

Benefits of Using the Correct Blade for Your Table Saw

The Importance of Blade Selection for Safety and Precision

Using the appropriate blade on your table saw is not just a matter of achieving the desired cut quality but also an essential aspect of ensuring your safety during the cutting process. The wrong blade can lead to kickback, uneven cuts, and potential damage to both the workpiece and the machine itself. By choosing the right blade, you can minimize the risks involved and maximize the accuracy of your cuts.

Table saw blades come in different sizes, tooth configurations, and materials, each designed for specific applications. It is crucial to consider factors such as the type of material you will be cutting, the desired result, and the overall condition of your table saw. By understanding these factors, you can select the most appropriate blade to achieve safe and accurate cuts.

In addition to safety, the correct blade selection also ensures the longevity of your table saw. Using the wrong blade can put excessive strain on the motor, arbor, and other components of the machine, leading to premature wear and potential damage. By using the right blade for the task at hand, you can extend the lifespan of your table saw and optimize its performance.

Common Types of Table Saw Blades

There are several common types of table saw blades available, each designed to cater to specific cutting needs. Here are a few examples:

- Rip Blades: These blades have a fewer number of large, closely spaced teeth designed to cut efficiently along the grain of the wood. They are ideal for ripping boards or cutting stock to width.

- Crosscut Blades: Crosscut blades have many more teeth than rip blades, and they are designed to produce smooth, clean cuts across the grain. They are suitable for cutting plywood, solid wood, and other materials where a fine finish is desired.

- Combination Blades: Combination blades are versatile blades that combine elements of rip and crosscut blades. They feature a mix of large and small teeth, making them suitable for a variety of cutting tasks.

- Dado Blades: Dado blades consist of two outer blades with a series of chippers that allow for the creation of wider grooves or dadoes. They are particularly useful for joinery, box joints, and rabbets.

These are just a few examples, and there are many other specialized blades available for specific applications. It is essential to understand the capabilities of each type of blade and choose the one that suits your needs and the materials you will be working with.

Additional Tips for Blade Selection

When selecting a blade for your table saw, consider the following tips to ensure the best results:

- Choose a blade with the correct tooth count for the job at hand. A higher tooth count generally provides a smoother cut, while a lower tooth count is better suited for rapid stock removal.

- Match the blade’s tooth geometry to the type of cut you need. Different tooth angles and shapes are designed for specific actions, such as ripping, crosscutting, or general-purpose cutting.

- Consider the material of the blade. Carbide-tipped blades tend to last longer and maintain their sharpness, but they are more expensive. High-speed steel blades are more affordable but may need to be sharpened more frequently.

- Check the diameter and arbor size of the blade to ensure compatibility with your table saw’s specifications.

- Regularly inspect your blades for any signs of damage, such as missing or chipped teeth. Replace damaged blades to ensure optimal performance and safety.

By following these tips and selecting the appropriate blade for your table saw, you can achieve clean, precise cuts while maintaining safety and prolonging the lifespan of your equipment.

Conclusion

In conclusion, it is not recommended to use a circular saw blade on a table saw. The differences in design and functionality between the two tools make it unsafe and potentially damaging to both the workpiece and the table saw itself. Instead, it is crucial to use the correct blade for the corresponding tool to ensure optimal performance, safety, and quality of cuts. Consider investing in a quality table saw blade that suits your specific cutting needs, and always prioritize safety by adhering to proper operating procedures and selecting the right tool for the job.

Can You Use a Circular Saw Blade on a Table Saw?

Wondering if it’s safe to use a circular saw blade on a table saw? Here are some key takeaways to consider:

- It is not recommended to use a circular saw blade on a table saw.

- Circular saw blades and table saw blades have different tooth configurations.

- Table saw blades are designed for ripping and cross-cutting wood on a table saw.

- Using a circular saw blade on a table saw can lead to kickback and other safety hazards.

- Always use the appropriate blade for the tool to ensure safety and optimal performance.

Frequently Asked Questions

Welcome to our FAQs on using circular saw blades on a table saw! If you’re wondering about the compatibility of these two tools, you’ve come to the right place. Read on to find answers to your burning questions!

1. Can I use a circular saw blade on a table saw?

No, you cannot use a circular saw blade on a table saw. While both types of saws have circular blades, they are designed differently and have distinct purposes. Circular saw blades are typically smaller in diameter and have a higher number of teeth. They are intended for handheld use and are perfect for making quick and rough cuts on various materials.

On the other hand, table saw blades are larger and have fewer teeth. They are specifically designed for use with a table saw, which allows for more precise and controlled cuts. Table saw blades are fixed in place and provide stability and accuracy, making them ideal for woodworking projects that require straight, clean, and smooth cuts.

2. Why is it not recommended to use a circular saw blade on a table saw?

It is not recommended to use a circular saw blade on a table saw because the two blades have different features and are designed for different applications. While it may seem like the blades are interchangeable, using a circular saw blade on a table saw can lead to safety hazards and inefficient results.

Circular saw blades are not built to withstand the high RPMs (rotations per minute) of a table saw. This can cause the blade to overheat, warp, or even break, posing a risk of accidents. Additionally, circular saw blades are not optimized for the cutting actions and precision that a table saw provides, resulting in less accurate cuts with rough edges and splintering.

3. Can I modify a circular saw blade to fit a table saw?

No, it is not recommended to modify a circular saw blade to fit a table saw. Blades designed for circular saws have different dimensions and features that are not compatible with a table saw. Altering the blade can compromise its structural integrity and lead to safety issues.

Instead, it is advisable to invest in a high-quality table saw blade that is specifically designed for use with a table saw. These blades are built to meet the requirements of the table saw, ensuring safety, efficiency, and optimal cutting performance.

4. What are the advantages of using a table saw blade on a table saw?

Using a table saw blade on a table saw offers several advantages. First and foremost, these blades are specifically designed for the table saw, ensuring compatibility and optimal performance. They are engineered to withstand the high RPMs of a table saw, providing durability and safety.

Table saw blades are also designed to deliver precise, clean, and accurate cuts. They have fewer teeth which help reduce the chance of kickback, making them safer to use. Additionally, table saw blades come in various types, such as rip blades, crosscut blades, and combination blades, allowing you to choose the right blade based on your cutting needs, whether it’s ripping through wood or making fine crosscuts.

5. How can I choose the right table saw blade for my needs?

To choose the right table saw blade for your needs, consider the type of cuts you will be making. If you primarily work with hardwood, a rip blade with fewer teeth is ideal for efficient cutting along the grain. For crosscuts or general woodworking, a crosscut blade with more teeth will deliver cleaner and smoother cuts.

Furthermore, the quality of the blade plays a significant role in the results. Look for blades made from high-quality materials, such as carbide-tipped blades, which offer longer-lasting sharpness and durability. Lastly, consider the thickness and size of the material you will be cutting and ensure that the blade’s specifications match your requirements.

Using Circular Saw Blades on a Table Saw for Woodworking

Summary

You may think it’s okay to use a circular saw blade on a table saw, but it’s not. These blades are not designed for the high speed and power of a table saw, and using them can be dangerous. Circular saw blades have a different tooth configuration than table saw blades, which can cause kickback and lead to accidents. It’s important to use the right blade for the right tool to ensure safety and proper cutting.

If you want to use a table saw, make sure to get the right blade for it. Table saw blades are specifically made to handle the power and speed of a table saw, providing clean and accurate cuts. They have a different tooth geometry that helps prevent kickback and ensures smooth cutting. So, remember, always use the correct blade for your tool to stay safe and get the best results.