Have you ever wondered if you can use deck screws for woodworking? Well, you’ve come to the right place! Woodworking is a popular hobby, and the type of screws you use can make a big difference in the strength and durability of your projects. In this article, we’ll explore whether deck screws are a suitable option for woodworking, and what considerations you should keep in mind. So let’s dive in and find out!

When it comes to woodworking, using the right screws is crucial. Deck screws are commonly used for outdoor projects like building decks or fences, but can they be used for woodworking projects as well? The short answer is yes, but there are a few things you need to consider. Woodworking projects often require different types of screws, depending on the materials you’re working with and the specific demands of your project.

One important factor to consider is the type of wood you’re using. Deck screws are designed to be corrosion-resistant, which makes them ideal for outdoor use where they’ll be exposed to moisture and harsh weather conditions. However, if you’re working with softer woods like pine or cedar, deck screws may have a tendency to split the wood, as they are often self-tapping and have aggressive threads. So, while deck screws can be used for woodworking, it’s important to choose the right type and size of screws for your specific project to ensure the best results.

Now that we’ve answered the question, “can you use deck screws for woodworking?” you’re one step closer to mastering your woodworking projects. By understanding the strengths and limitations of deck screws, you can make an informed decision when choosing the right screws for your woodworking endeavors. So grab your tools and get ready to create something amazing!

Can You Use Deck Screws for Woodworking?

Woodworking requires a variety of fasteners, one of which is screws. They are essential for joining pieces of wood together securely. However, when it comes to choosing the right screws for your woodworking projects, you may wonder if you can use deck screws. Deck screws are specifically designed for outdoor decking applications, but can they be used for woodworking as well? In this article, we will explore the compatibility of deck screws for woodworking projects and discuss their advantages and disadvantages.

1. Understanding Deck Screws

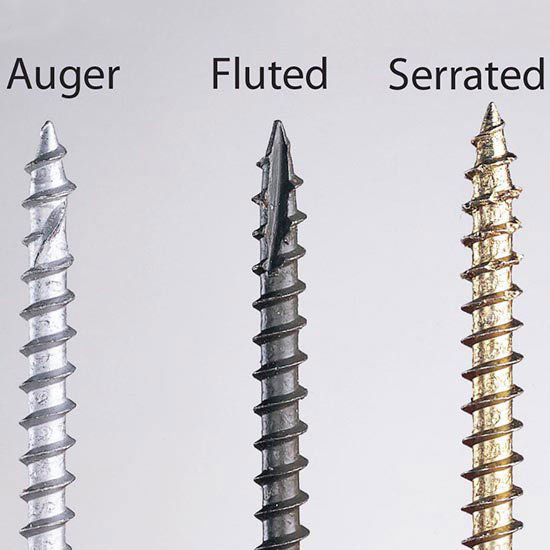

Deck screws are specifically engineered to withstand the harsh outdoor elements. They are made from corrosion-resistant materials, such as stainless steel or coated steel, to prevent rusting and damage from exposure to moisture. Deck screws have unique features, including a sharp point for easy penetration, deep threads for better grip, and a countersunk head that allows for flush or recessed installation.

When it comes to woodworking, deck screws can be a viable option depending on the project. They offer excellent holding power and can securely join pieces of wood together. However, there are a few considerations to keep in mind.

Firstly, deck screws may not be available in the same variety of lengths and sizes as traditional woodworking screws. This can limit their usability in certain woodworking applications where specific dimensions are crucial. Additionally, deck screws are typically coarse-threaded, which may not be ideal for certain woodworking projects that require a finer thread pitch for a more delicate finish.

2. Pros and Cons of Using Deck Screws for Woodworking

Before deciding whether to use deck screws for your woodworking projects, it’s essential to weigh the pros and cons. Here are a few advantages and disadvantages to consider:

Advantages:

– Durability: Deck screws are designed to withstand outdoor conditions, making them highly durable for woodworking projects that will be exposed to the elements.

– Holding Power: Deck screws have excellent holding power, thanks to their deep threads and sharp points. They can securely fasten wood pieces together, providing stability and strength.

– Corrosion Resistance: One of the main benefits of deck screws is their resistance to corrosion. This ensures that your woodworking projects will stand the test of time.

Disadvantages:

– Limited Size Options: Deck screws may not be available in the same variety of lengths and sizes as standard woodworking screws, potentially limiting their usability in certain projects.

– Coarse Thread: The coarse thread on deck screws may not be suitable for all woodworking applications. It may be too aggressive or not provide the fine finish required for delicate projects.

– Aesthetic Considerations: Depending on the project, the countersunk head of deck screws may not offer the desired aesthetic finish. Traditional woodworking screws often have decorative heads that add an extra touch of elegance to the piece.

3. When to Use Deck Screws for Woodworking

While deck screws may not be the optimal choice for every woodworking project, there are specific instances where they can be used effectively. Here are a few scenarios where deck screws can be a suitable option:

– Outdoor Furniture: If you are building outdoor furniture that will be exposed to the elements, deck screws are a reliable choice due to their corrosion resistance.

– Structural Projects: When working on structural woodworking projects, such as building a shed or a deck, deck screws can provide the necessary strength and durability.

– Utility Projects: For utility-based projects that prioritize functionality over aesthetic appeal, deck screws can be a cost-effective and efficient option.

Overall, while deck screws can certainly be used for woodworking projects, it’s important to consider the specific requirements of your project before making a final decision. Assess the size, thread pitch, and aesthetic considerations to ensure that deck screws are the right choice for your woodworking needs.

Benefits of Using Deck Screws for Woodworking

When considering the use of deck screws for woodworking projects, it’s essential to weigh the benefits they offer. While they may not be the most versatile option, deck screws have distinct advantages that make them suitable for certain applications. Let’s explore the benefits of using deck screws for woodworking:

Deck Screws vs. Traditional Woodworking Screws: A Comparison

In the world of screws, traditional woodworking screws have long been the go-to choice for many craftsmen. However, with the introduction of deck screws, a debate has emerged regarding which one is superior. Let’s compare deck screws and traditional woodworking screws in terms of key factors:

Tips for Using Deck Screws in Woodworking Projects

If you’ve decided to use deck screws for your woodworking projects, here are some helpful tips to ensure a successful outcome:

Conclusion

Using deck screws for woodworking can be a viable option depending on the specific requirements of your project. They offer durability, holding power, and corrosion resistance, making them suitable for outdoor furniture, structural projects, and utility-based woodworking. However, it’s important to consider their limitations, such as limited size options and coarse thread. By carefully assessing your project’s needs and considering the pros and cons, you can confidently decide whether deck screws are the right choice for your woodworking endeavors. Remember to always prioritize safety and precision when working with any type of screws in your woodworking projects.

Can You Use Deck Screws for Woodworking?

Yes, you can use deck screws for woodworking, but it’s not always the best choice. Here are some key takeaways to consider:

- Deck screws have coarse threads designed for outdoor use and to grip wood securely.

- They are not as aesthetically pleasing as other woodworking screws.

- Deck screws can be difficult to countersink properly in woodworking projects.

- They may not provide enough holding power for certain woodworking applications.

- For quality woodworking projects, it is recommended to use specialized woodworking screws.

Frequently Asked Questions

In woodworking, the choice of screws is crucial to ensure the longevity and durability of your projects. While deck screws may seem similar to woodworking screws, there are some key differences that need to be considered. Here are some common questions related to using deck screws for woodworking.

1. What are the main differences between deck screws and woodworking screws?

Deck screws are designed specifically for outdoor decking applications, where they need to withstand exposure to the elements. They typically have a corrosion-resistant coating and are made from materials like stainless steel or coated steel. Woodworking screws, on the other hand, are designed for indoor use and often have a different thread design and no coating.

Additionally, woodworking screws often have a smaller head size, allowing for a flush or countersunk finish, while deck screws usually have a larger head designed for use with exterior decking materials.

2. Can you use deck screws for woodworking projects?

While it is possible to use deck screws for woodworking projects, it is generally not recommended. Deck screws may not provide the same level of structural integrity and holding power as dedicated woodworking screws. The larger heads and coarse threads of deck screws may also result in splitting or damaging the wood.

For optimal results, it is advisable to use woodworking screws that are specifically designed for the task. These screws are often available in different lengths, materials, and head styles, allowing you to choose the right screws for your project.

3. Are there any advantages to using deck screws for woodworking?

While deck screws may not be the ideal choice for woodworking projects, there are some situations where they may be used as an alternative. If you are working on a project that requires a temporary connection or if you are unable to find woodworking screws, deck screws can serve as a temporary solution.

However, it is important to keep in mind that deck screws may not provide the same level of durability and longevity as woodworking screws. It is recommended to use deck screws as a temporary option only and replace them with proper woodworking screws as soon as possible.

4. What are the potential drawbacks of using deck screws for woodworking?

Using deck screws for woodworking projects can have several drawbacks. The larger heads of deck screws may not provide a clean, flush finish, which can be undesirable for certain woodworking applications. The coarse threads can also lead to splitting or damaging the wood, especially when working with delicate or hardwoods.

In addition, the corrosion-resistant coating on deck screws may not be necessary for indoor woodworking projects and can add unnecessary cost. It is generally more cost-effective and practical to use woodworking screws that are specifically designed for the task.

5. How can I ensure the longevity and durability of my woodworking projects?

To ensure the longevity and durability of your woodworking projects, it is important to choose the right screws for the job. Use dedicated woodworking screws that are designed for indoor use and have the appropriate thread design, head size, and material.

Additionally, consider pre-drilling pilot holes to prevent splitting and use clamps or other securing methods to hold the wood pieces in place during assembly. Properly sealing or finishing the wood can also help protect it from moisture damage and enhance its durability.

Summary

So, can you use deck screws for woodworking? Well, it depends on what you’re making!

Deck screws are great for outdoor projects like decks or fences, but for indoor furniture or delicate pieces, you’ll want to use wood screws. Wood screws have a sharper point and are less likely to split the wood. Remember, using the right screw for the job will ensure a stronger and more secure final product!